Horizontal Load Case and Tray Packers

Accessible, Versatile Case & Tray Packing

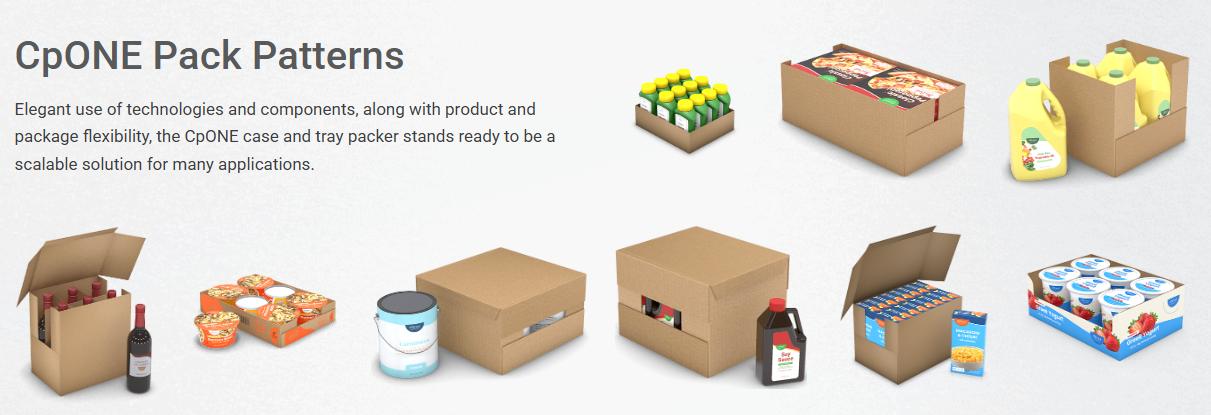

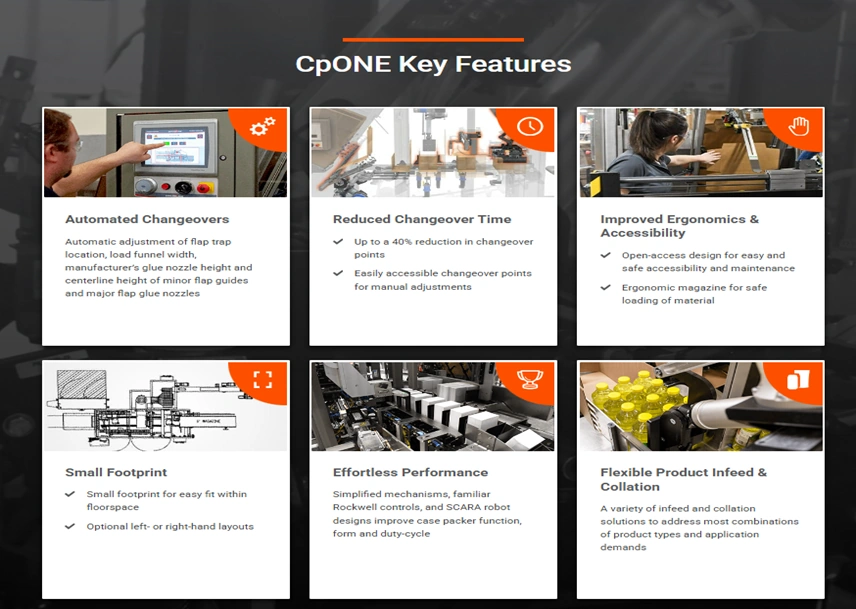

The CpONE case packer delivers a powerful blend of simplicity, performance, and accessibility, making it the ideal solution for manufacturers seeking straightforward, efficient secondary packaging automation.

Specifications:

|

Speed

|

Up to 45 cases/minute; Scalable configurations address different applications, speed & investment levels |

|

Case Types

|

Wraparound cases, knockdown cases & trays

|

|

Frame/Finish

|

Powder coated cold-rolled bar stock, sheet & tubular steel; Axalta 616 Gray Metallic color;Washdown options available

|

|

Magazine Capacity

|

6′ (1829 mm) |

| Glue System | Nordson ProBlue® Flex |

| Adjustments | HMI selectable recipes, automatic position actuators, threaded screws, hand wheels & hand knobs with position pointers & numeric scales |

| Safety | Guarded for current OSHA standards; Clear sightlines through & around the machine; Respects one-meter-reach rule |

| Electrical | Rockwell Automation programmable logic controller, servo & AC drives, & PanelView+ HMI |

| Servo Motors | Rockwell VPL & Wittenstein TPM, NEMA 12 wiring & enclosures, floor mounted, overhead mounted optional; Washdown options available |

| Power | 480 V, 50/60 HZ |

| Air | 90 PSI (6.2 bar) |

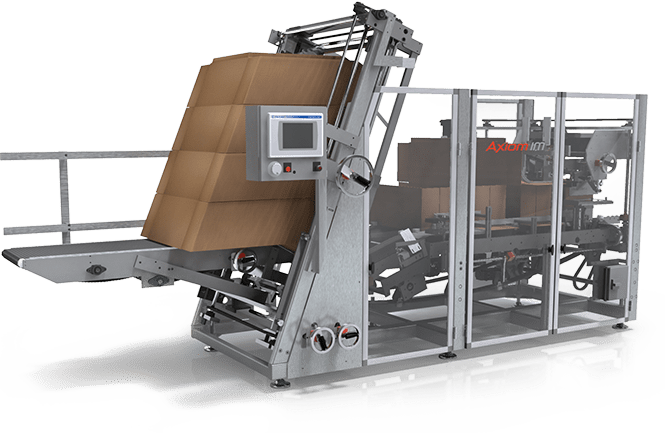

High-Speed, Customized Case & Tray Packing

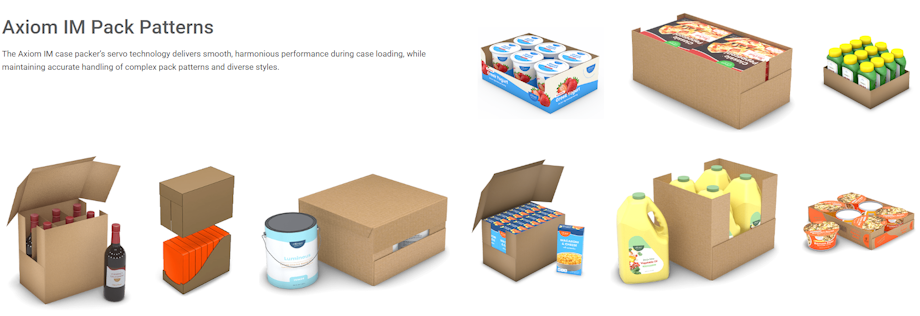

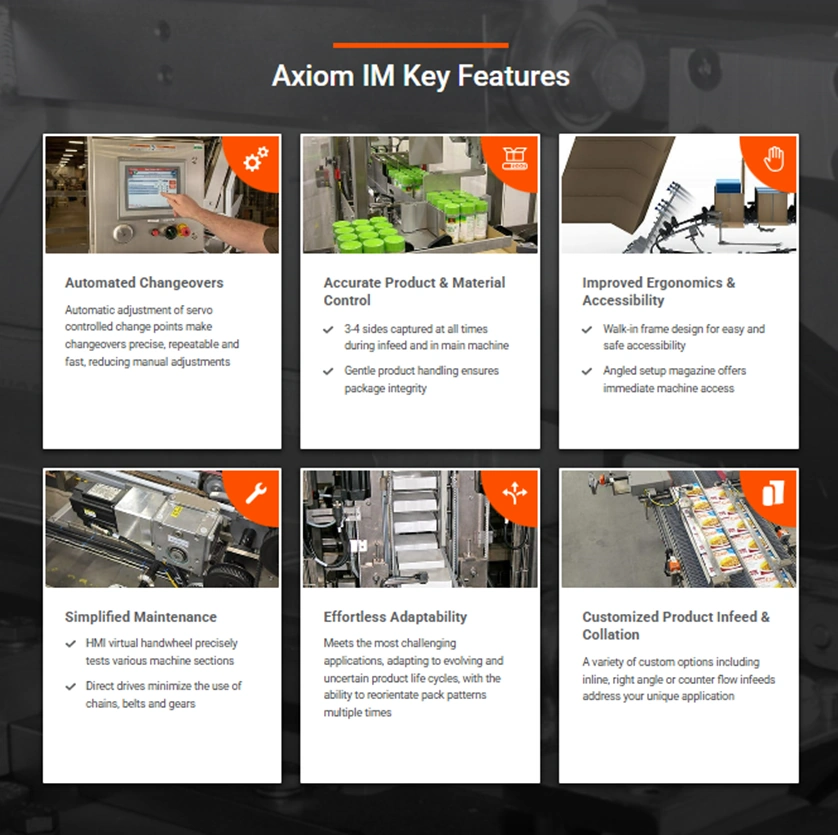

The Axiom IM case packer is the industry-proven workhorse for high-speed, customizable case packing, operating at 45–60 cases per minute with servo-driven precision.

Specifications:

| Drive | Servo motors |

| Flight Chains | #2060 chains |

| Speed | Up to 45 cases/minute; Product and pack pattern dependent |

| Product/Package Size Range | Per project specification |

| Magazine Capacity | 6′ (1829 mm); 8 blanks per inch |

| Frame/Finish | Powder-coated cold-rolled steel; optional stainless steel frame. All parts in contact with product are stainless steel, anodized aluminum and plastic OEM parts with manufacturer’s standard finish. |

| Glue System | Nordson ProBlue® Flex |

| Flap Closing & Compression | Servo motors |

| Adjustments | Threaded screws, handwheels and hand knobs with position pointers and scales; Digital scales, phase adjustments and recipe control of servo motions and glue (optional) |

| Safety | Guarded for current OSHA standards; Clear sightlines through and around machine; Respect one-meter-reach rule |

| Electrical | Allen Bradley motion/logic control, PanelView, NEMA12 wiring and enclosures; NEMA 4/4X wiring and enclosures (optional); Washdown options available for stainless steel frame upgrade |

| Power | 480 V, 50/60 HZ, 3 PH |

| Air | 90 PSI (6.2 bar) |

Ultra-Fast Continuous Motion Case & Tray Packer

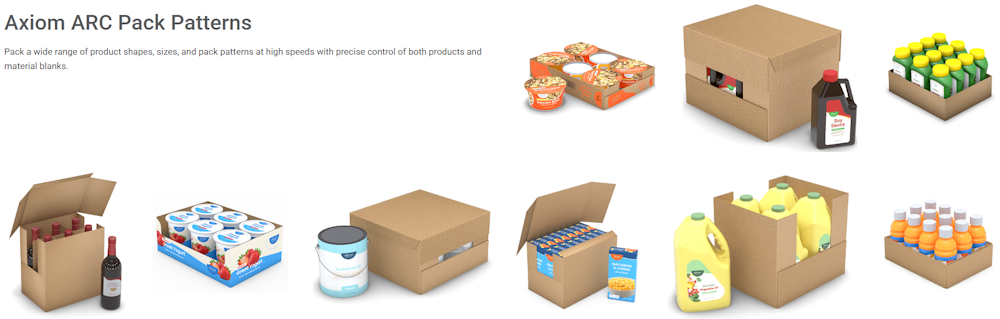

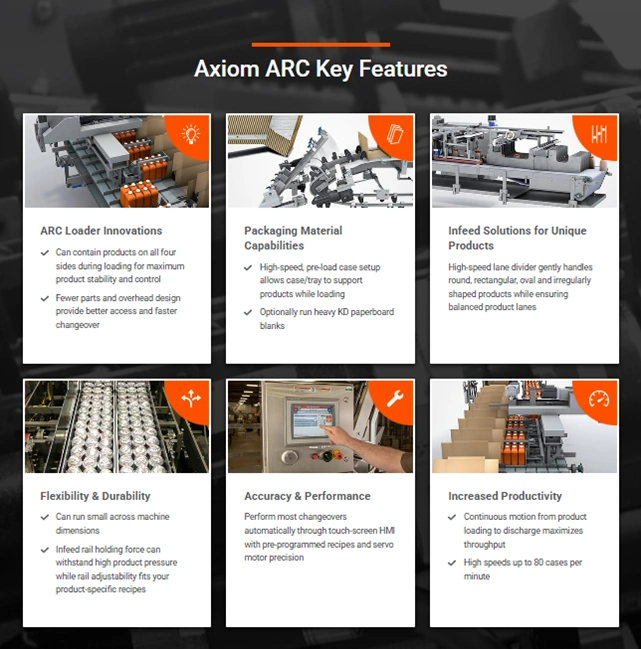

The Axiom ARC case packer redefines high-speed case packing, delivering exceptional product stability at speeds up to 80 cases per minute with continuous motion technology.

Specifications:

| Speed | Up to 80 cases/minute; Product and pack pattern dependent |

| Min. Case Size | 6″ L* x 8″ W x 3.5″ V |

| Max Case Size | 12″ L* x 21″ W x 13″ V |

| Case Types |

Wraparound cases (RSC, POL FOL or harness-style flaps); Pre-glued knock-down KD cases; |

| Magazine Capacity | 6′ (1829 mm) |

| Glue System | Nordson ProBlue® Flex |

| Product Loading | High-speed continuous-motion ARC loader; Product containment and product stabilizing features are available |

| Adjustments | Tool-free changeover, HMI selectable recipes, threaded screws, handwheels, and handknobs with position pointers and digital scales |

| Frame / Finish | Powder-coated tubular cold-rolled steel; Axalta 616 Gray Metallic color |

| Drive | Servo motors |

| Electrical | Rockwell Automation (AB) programmable logic controller, servos, drives and PV+ HMI; NEMA 12 wiring and enclosures; Washdown (optional) |

| Power | One main drop and one glue drop 480 VAC, 50/60 HZ, 3 PH; Other power sources available |

| Air | 90 PSI (6.2 bar) |

* Note: L indicates travel direction

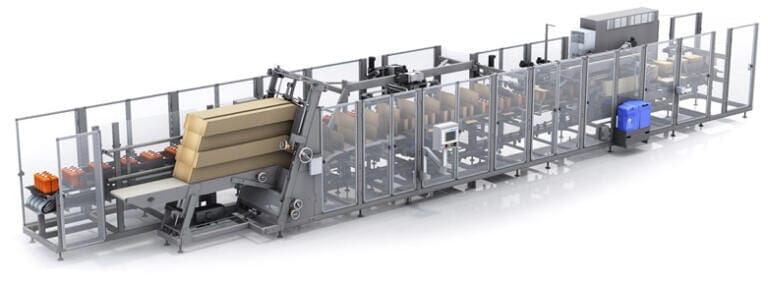

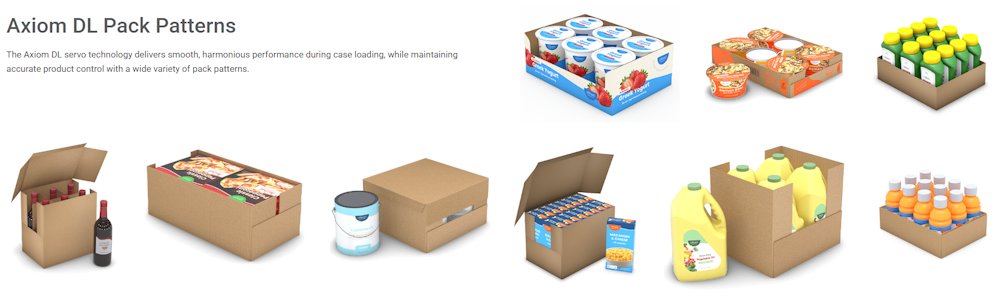

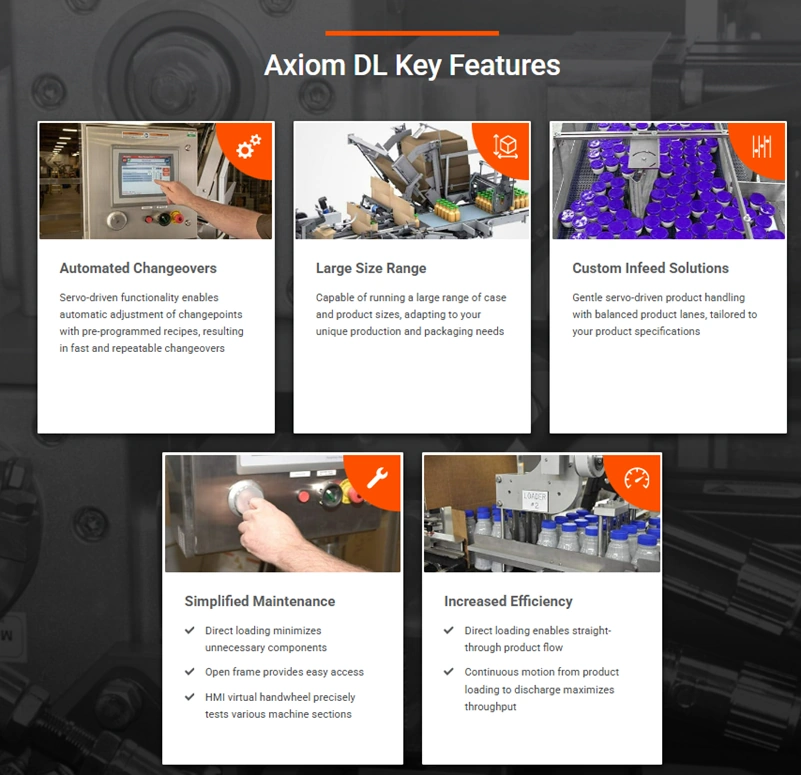

Mid-Speed Continuous Motion with Direct Case Loading

Operating at speeds up to 55 cases per minute, it uses an overhead sweeping motion to load products directly onto case or tray blanks, ensuring compact design and straight-through product flow. Featuring servo-driven automation, Axiom DL offers quick changeovers, precise case loading, and efficient infeed technology, making it ideal for cartons, bottles, cans, jars, and jugs.

Specifications:

Speed

Up to 55 cases/minute

Flight Chains

2060 chains

Drive

Servo motors

Product / Package Size Range

Per project specification

Magazine Capacity

6′ (1829 mm);

8 blanks per inch

Frame / Finish

Powder-coated cold-rolled steel; optional stainless steel frame. All parts in contact with product are stainless steel, anodized aluminum and plastic OEM parts with manufacturer’s standard finish.

Glue System

Nordson ProBlue® Flex

Adjustments

Threaded screws, handwheels and hand knobs with position pointers and scales; Digital scales, phase adjustments and recipe control of servo motions and glue (optional)

Safety

Guarded for current OSHA standards; Clear sightlines through and around machine; Respect one-meter-reach rule

Electrical

Allen Bradley motion/logic control, PanelView, NEMA12 wiring and enclosures; NEMA 4/4X wiring and enclosures (optional); Washdown options available for stainless steel frame upgrade

Power

480 V, 50/60 HZ, 3 PH

Air

90 PSI (6.2 bar)

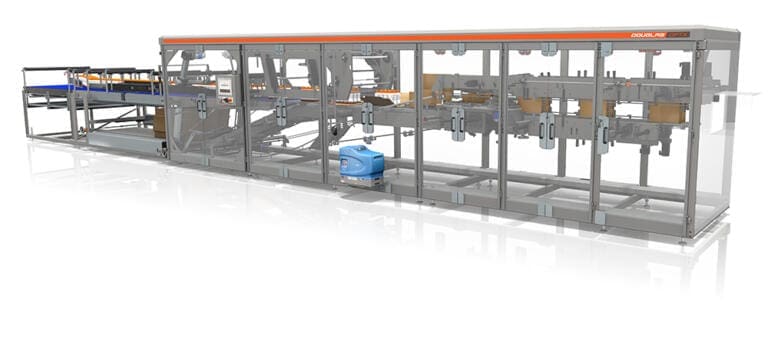

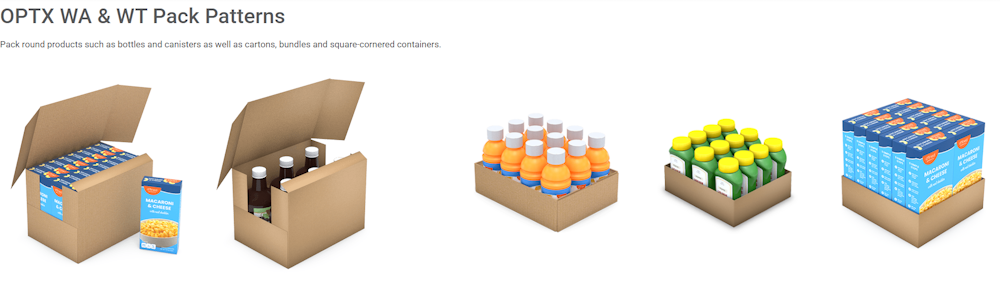

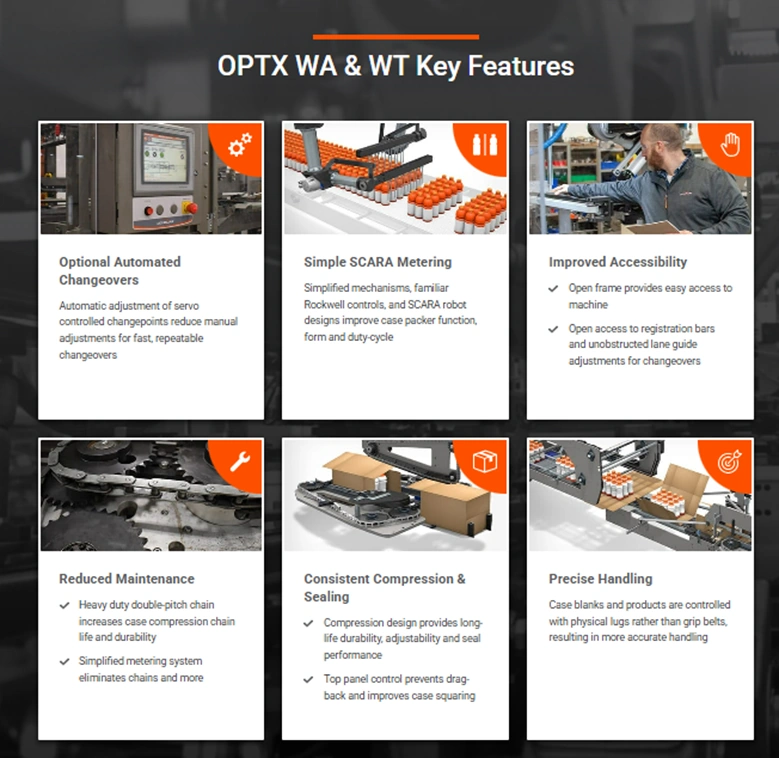

High Performance for Wraparound Packaging

The OPTX WA & WT wraparound case and tray packers offer adaptable, consistent product loading as well as reliable case and tray forming and sealing.

Specifications:

| Speed | Up to 80 packs/minute |

| Case/Tray Types | OPTX WA: Wraparound cases; OPTX WT: Wraparound cases and trays |

| Min. Case Size | 6″ (152 mm) x 5” (127 mm) x 5.75” (146 mm)* |

| Max Case Size | 20” (508 mm) x 14” (356 mm) x 16” (406 mm)*; Max Case Blank: 27“ x 54” |

| Min Tray Size | 5” (127 mm) x 3” (76 mm) x 9.25” (235 mm)* |

| Max Tray Size | 13” (330 mm) x 14” (356 mm) x 22” (558 mm)*; 12” (305 mm) max vertical if shrink wrapping downstream |

| Magazine Capacity | 10’ (3 m) |

| Glue System | Nordson ProBlue® Flex |

| Adjustments | HMI selectable recipes, automatic position actuators, threaded screws, hand wheels and hand knobs with position pointers and numeric scales |

| Guarding | Category 3 guarding; Full length 1/2” (12.7 mm) acrylic guard doors (main machine) and clear polycarbonate |

| Electrical | Rockwell Automation (AB) programmable logic controller, servo and AC drives, PanelView+ HMI; Washdown options available |

| Power | 480 V; 50/60 HZ; 3 PH; Second 480 V drop for glue unit |

| Air | 90 PSI (6.2 bar) |

*Note: Measurements indicate Direction of Travel x Vertical x Across Machine

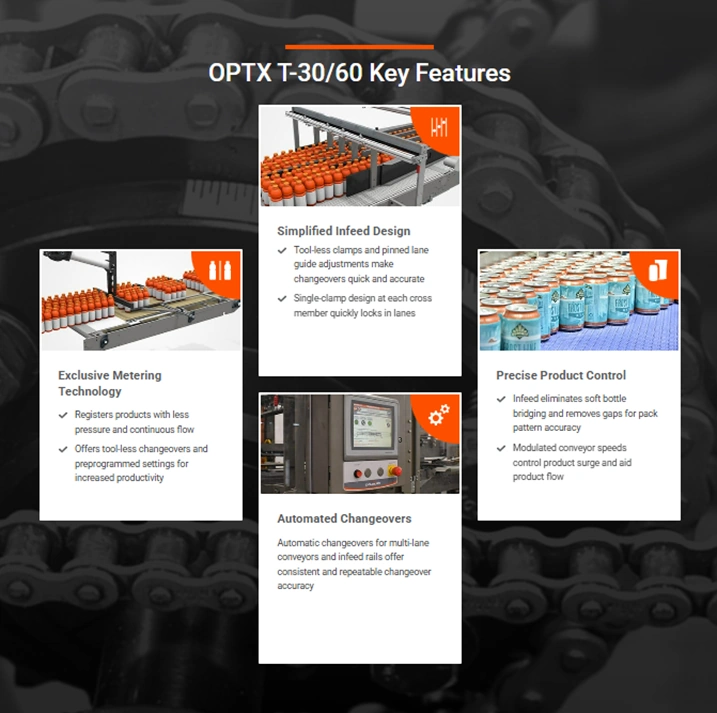

Simple, Accurate Tray Packing

The OPTX T-30 and T-60 tray packers offer precise tray forming, smooth product infeed, and accurate product metering in an uninterrupted workflow.

OPTX T-30/60 Pack Patterns

Achieve reliable tray forming and pack pattern accuracy for both round and rectangular shaped products.

Specifications:

| Speed OPTX T-30 | Up to 30 cycles/minute |

| Speed OPTX T-60 | Up to 60 cycles/minute |

| Min. Package Size | 5″ (127 mm) x 3″ (76 mm) x 9.5″ (241 mm)* |

| Max Package Size | 14″ (355 mm) x 12″ (305 mm) x 22″ (558 mm)* |

*Note: Measurements indicate Direction of Travel x Vertical x Across Machine

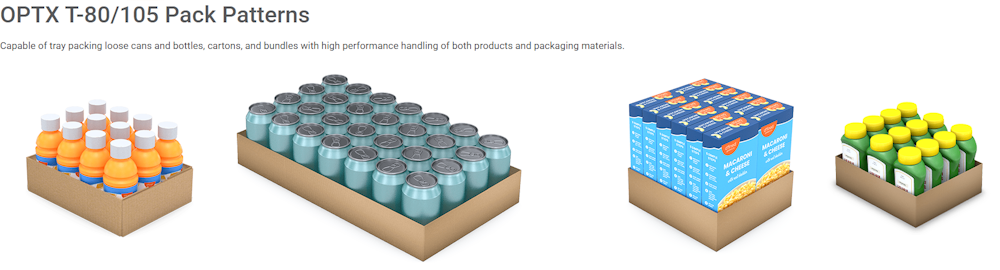

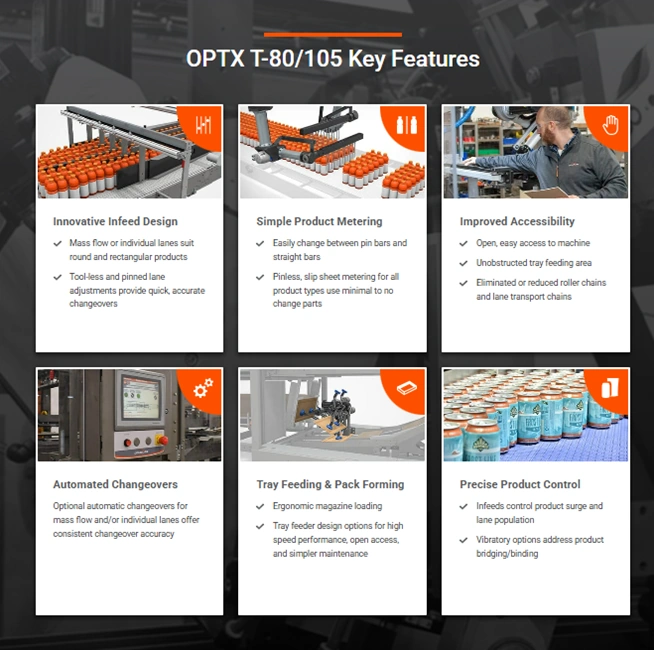

High Speed Tray Packing

The OPTX T-80 and T-105 offer precise tray forming, smooth product infeed, and accurate product metering with a high-speed workflow.

Specifications:

| OPTX T-80 Speed | Up to 80 cycles/minute |

| OPTX T-105 Speed | Up to 105 cycles/minute |

| Min. Package Size | 5″ (127 mm) x 3″ (76 mm) x 9.25″ (235 mm)* |

| Max Package Size | 13″ (330 mm) x 12″ (305 mm) x 22″ (558 mm)* |

*Note: Measurements indicate Direction of Travel x Vertical x Across Machine

Specifications:

| OPTX T-80 Speed | Up to 80 cycles/minute |

| OPTX T-105 Speed | Up to 105 cycles/minute |

| Min. Package Size | 5″ (127 mm) x 3″ (76 mm) x 9.25″ (235 mm)* |

| Max Package Size | 13″ (330 mm) x 12″ (305 mm) x 22″ (558 mm)* |

*Note: Measurements indicate Direction of Travel x Vertical x Across Machine

GuidePoint™

Empower your workforce and drive productivity with GuidePoint, a tablet-based knowledge and support center that offers a game-changing alternative to traditional manuals and machine documentation.