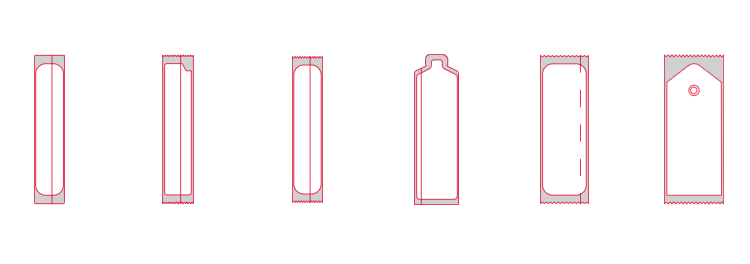

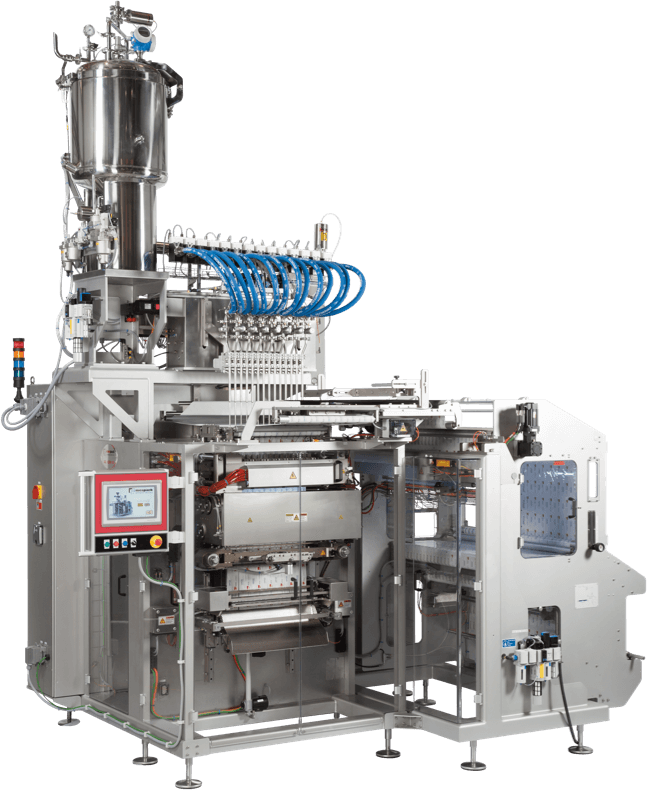

Vertical Form Fill and Seal

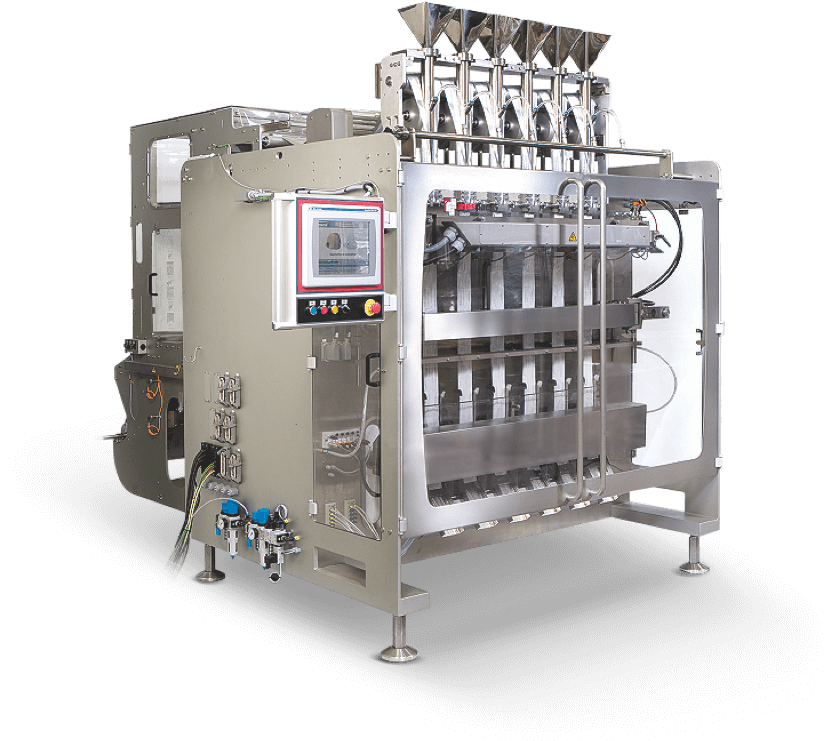

MODELS MS1200, MS1000, MS600, MS350

Main standard features

- Independent servo driven film unwind system

- Pneumatical film brake system with proportional unwind speed

- Servo driven main film drive system

- Servo driven horizontal seal jaws

- Pneumatical expandible reel shaft

- Adjustable horizontal cutting knives (flat or zig-zag)

- Motor driven circular knives

- PLC independent temperature control seal bars

- PLC auto-controlled lubrication

- Free operation access to side of the machine

- Micro-switch protected transparent polycarbonate guardings

- Integrated electrical cabinet (optional)

- Full servo version available

- Laser coders and scorers (optional)

- ATEX compliance (optional)

- Film sterilization system (optional)

- Laminar flow (optional)

- Integrated film splice system in the unwinder (optional)

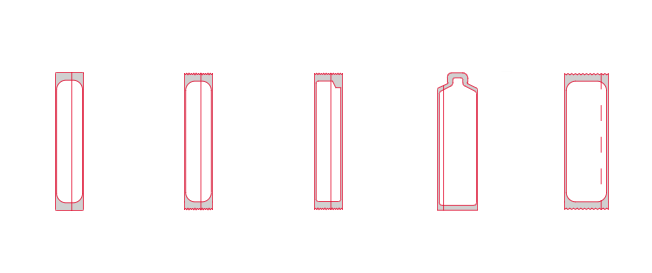

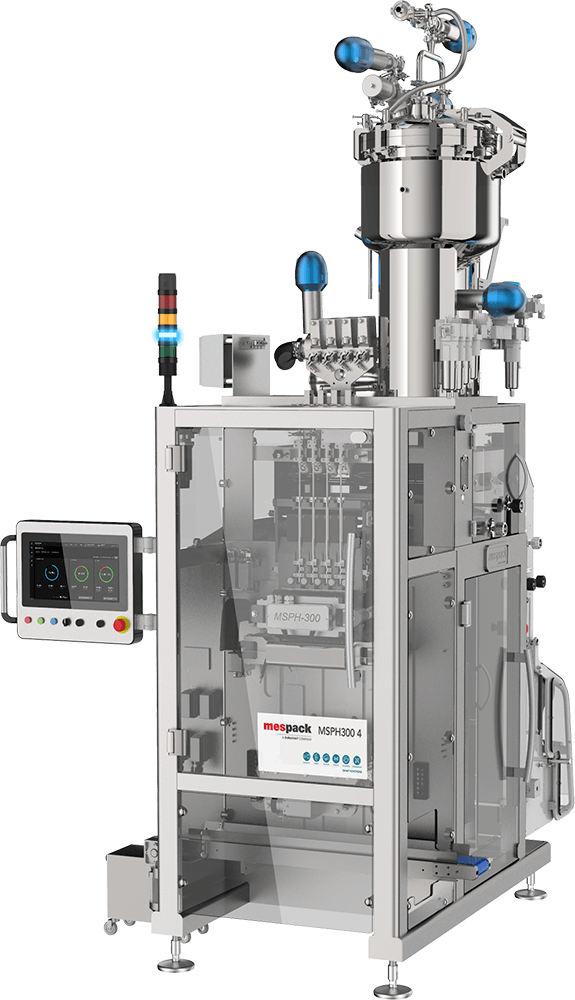

MODELS MSPH600, MSPH300

Main standard features

- Full servo and stainless-steel machine

- Protocol DQ/IQ/OQ/PQ

- Artificial vision camera

- Individual exit chute

- High performance, precision, and reliability

- Compliance with GMP, GAMP5, FDA, and 21 CFR Part 11

- Athena enabled (HMI and IIoT)

- Up to 14 lanes and 840 sticks per minute

MODELS ML1200, ML1000

Main standard features

- One brushless motor for the main film drive system and vertical cutting knives

- Two brushless motors for unwinder

- Two brushless motors for the vertical seal bars

- One brushless motor for horizontal cutting knives

- One brushless motor for horizontal seal bars

- Mono block tubular steel frame

- Integrated electric cabinet

- Micro switch protected polycarbonate guardings

- 18.5” color touch screen

- Free access to the entire machine

- PLC controlled temperatures in each seal bar

- PLC controlled auto lubrication

- Splice table in unwinder for quick reel change

- Auger cleaning management system

- Automatic reel edge aligner in unwinder

- TPM features

- CIP facilities

- Compliance with the primary manufacturing standards

- Laser coders and scorers (optional)

- ATEX compliance (optional)

- Film sterilization system (optional)

- Laminar flow (optional)

MODELS MLC1200, MLC1000

Main standard features

- One brushless motor for the main film drive system and vertical cutting knives

- Two brushless motors for unwinder

- Two brushless motors for the vertical seal bars

- One brushless motor for horizontal cutting knives

- One brushless motor for horizontal seal bars

- Mono block tubular steel frame

- Integrated electric cabinet

- Micro switch protected polycarbonate guardings

- 18.5” color touch screen

- Free access to the entire machine

- PLC controlled temperatures in each seal bar

- PLC controlled auto lubrication

- Splice table in unwinder for quick reel change

- Auger cleaning management system

- Automatic reel edge aligner in unwinder

- TPM features

- CIP facilities

- Compliance with the primary manufacturing standards

- Laser coders and scorers (optional)

- ATEX compliance (optional)

- Film sterilization system (optional)

- Laminar flow (optional)