Starwheel (Pot Filling Closing | Pot Filling Machines | Starwheel | Starwheel | Packaging Automation Ltd)

The Starwheel offers the ultimate in pot sealing and closing flexibility, in either a single or twin wheel configuration. It is designed to handle rigid walled, non de-nestable containers with the option to create a seal using a pre-cut lid or reel fed film.

The Starwheel can also be integrated with an automatic screw capper or induction sealer as well as a wide range of fillers to give a fully versatile solution.

Production speeds are dependent on the product consistency, fill volume and closure type but can be up to 100 containers per minute.

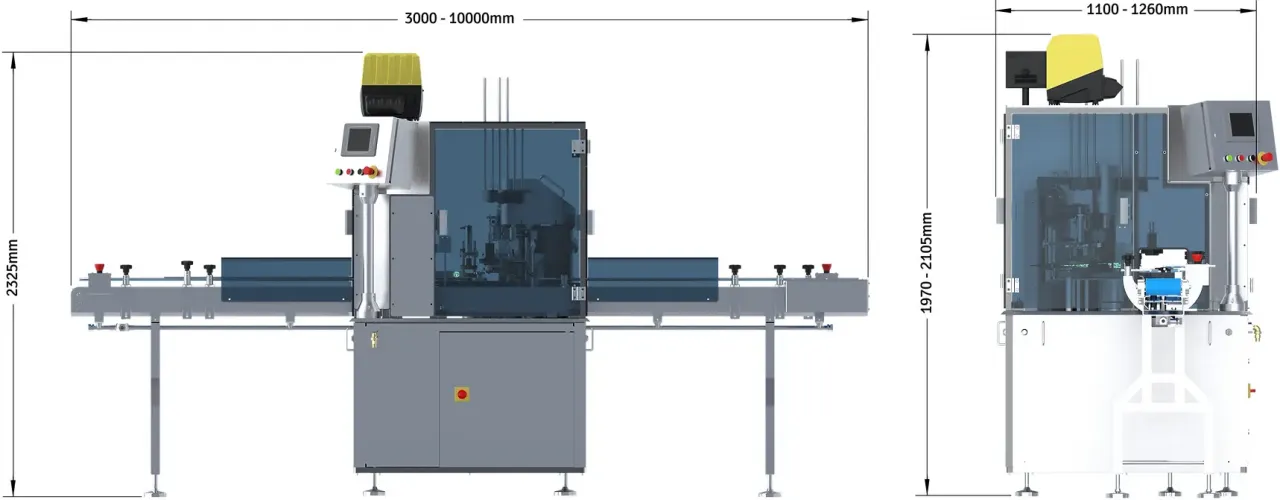

Technical Specifications:

| Starwheel Specifications | |

| Height | 1970 – 2105mm |

| Width | 3000 – 10000mm |

| Depth | 110 – 1260mm |

| Electrical Supply | 32A 415V 3 Phase N+E 16A max/phase 50/60Hz |

| Pneumatic Supply | 10cfm 80psi (5.5bar) |

Features:

Machine Features

- Single or twin lane option

- Simple fully automatic operation

- Multi positional operator friendly touch screen provides real time machine status, self diagnostic and operator prompts

- A very robust structure and component design means greater reliability and reduced downtime

- No container no index detection sensor

- Automatic pre-cut lid pick and place

- Pre-cut lid, foil and plastic sealing

- High accuracy indexing rotary table

- Digital temperature control ensures that an accurate temperature is maintained

- Pre-set accurate recipe based program

- Hygienic, wash down construction to food industry standards

- Stainless steel modular in-feed and eject conveyor

- Sale, lease purchase and rental options tailored to suit all requirements

Materials

The Starwheel has the ability to heat seal reel fed film, pre-cut foil, paper or laminate lids to preformed trays and containers of CPET, Polypropylene, PVC, Styrene, Board, Smooth walled foil, pre-cut board, Paper, Plastic, and many other types of container.

Options

- MAP-F (Modified Atmosphere Packaging)

- Automatic over cap applier

- Can be integrated with automatic screw capper or induction sealer

- Multi fill stations for layered products

- Date coder integration ready

- Servo controlled volumetric piston filler

- Stainless steel 55 litre machine mounted product tank

- Product tank agitation

- Double skinned tanks for hot products

- CIP – Clean In Place process options

- Tank temperature probe for accurate product temperatures

- Tank level probe for automatic fill

- Hot product fill nozzle and piston parts

- Interchangeable nozzle types

- Closed loop weight control system linked to online check-weigher for automatic fill volume adjustment

- Stainless steel laser cut guards

- Rotary accumulation table

- Can be integrated with additional dry product filling equipment

Packaging Materials:

- Plastic trays

PP, A-PET, C-PET, R-PET, PS

- Pulp and Board trays

Pre-cut board or pulp trays

- Lidding materials

Film lidding material on a reel

Pre-cut foil, paper or laminate lids