Shrink Tunnels

As efficient and flexible as our packaging machines

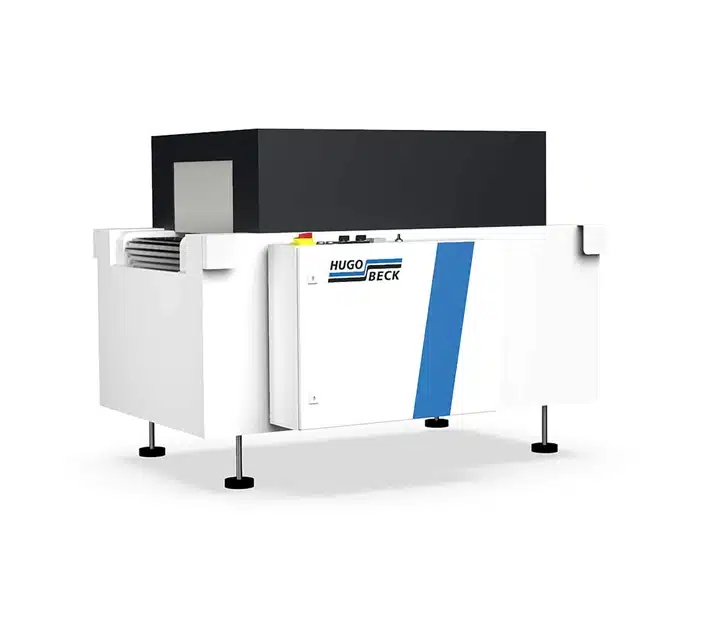

Items that have initially been bagged using a machine from Hugo Beck often need to be shrunk so as to ensure a tight-fitting film and the perfect packaging finish to meet the highest standards. Adapted for each packaging system, Hugo Beck supply’s the appropriate shrink tunnel in all sizes and performance ranges for the production of high-quality shrink packaging. As such, Hugo Beck manufacture shrink tunnels in a number of versions, with a variety of rods and chains that operate like a link mesh belt. Textile mesh belts are also possible for very light products. In each case, the length of the shrink tunnel depends on the speed of packaging and on the film material selected. The decision on whether to use a shrink tunnel with circulating air or convection principle is defined depending on the individual product application of the customer.

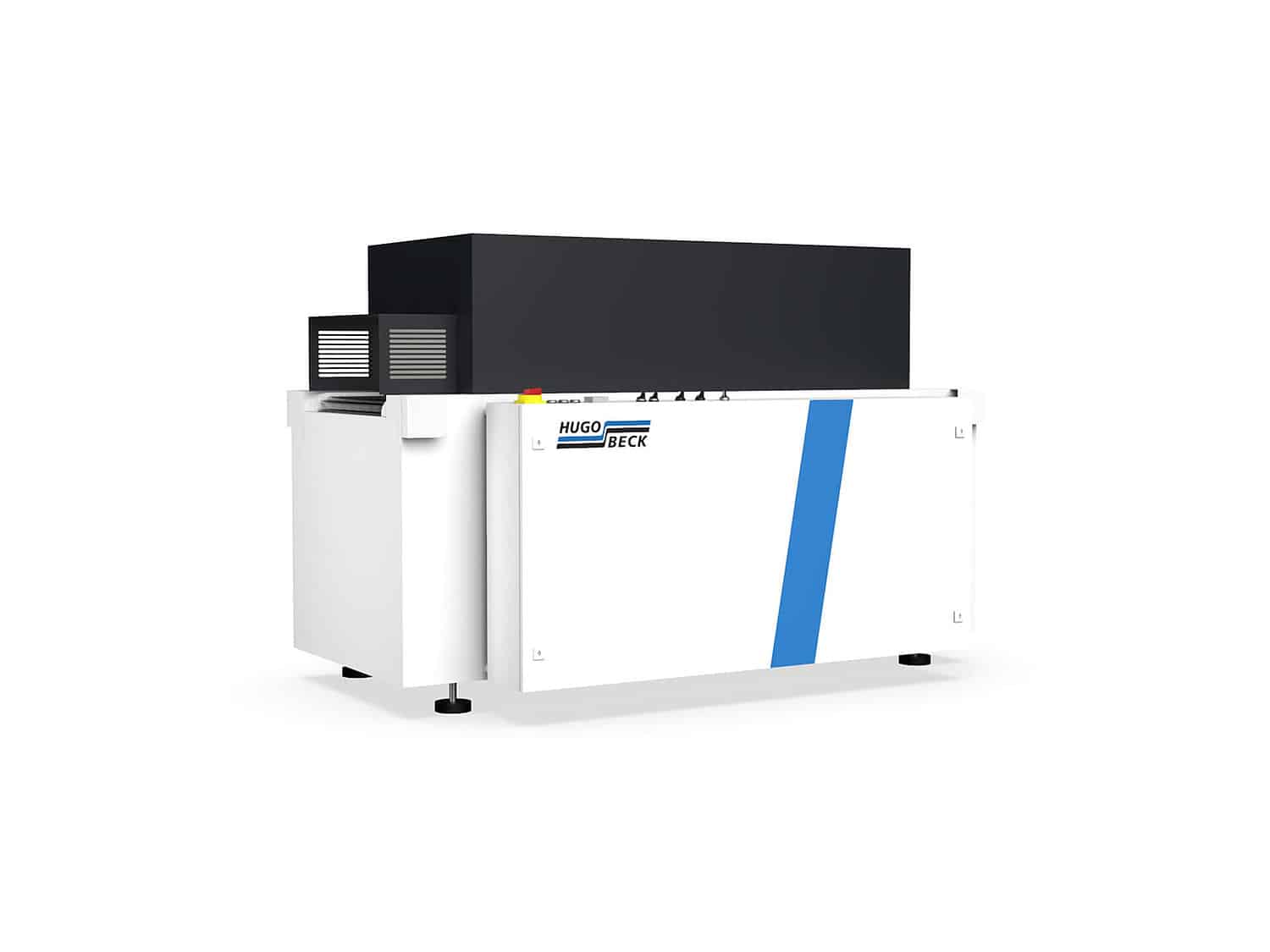

Circulating Air (Type SLB)

A tunnel with high thermal efficiency and various adjustment options for optimum shrink results. The shrink tunnel blows the heated air onto the product at the infeed area from the bottom and both sides. This creates an air flow towards the outfeed area, where the heated air continuously enters a vacuum and recirculates.

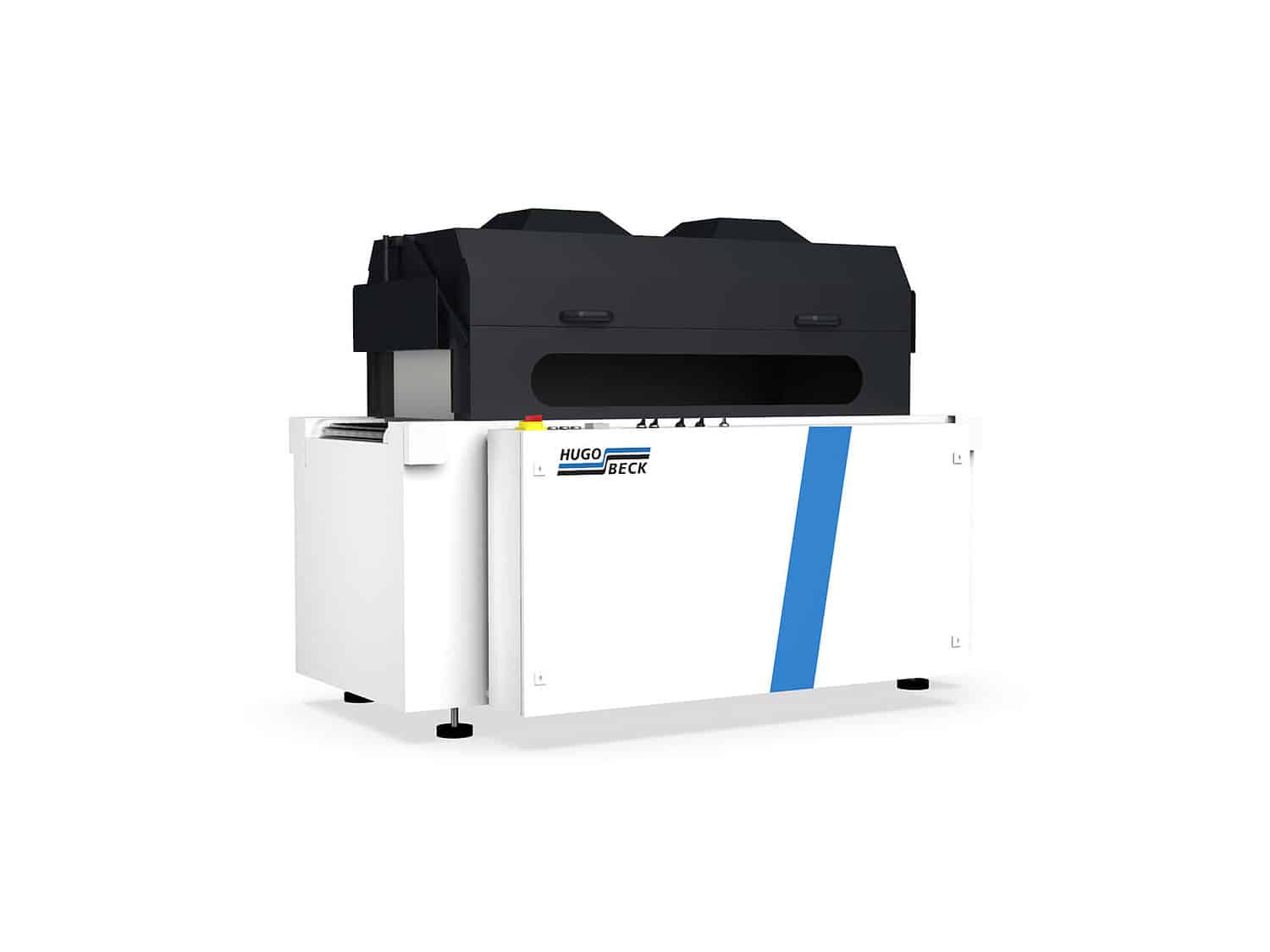

Convection (Type SL)

Optimum performance thanks to the high air flow coupled with low energy consumption. Ventilators control and evenly distribute the heated air within the shrink tunnel. This produces perfect shrink results while keeping adjustments to an absolute minimum.

Technical Data

| Tunnel-Length | 1,20 m – 5,5 m |

| Tunnel-Width | 0,5 m – 1 m |

| Downloads | Brochure Complete Packaging Solutions |

Other Resources

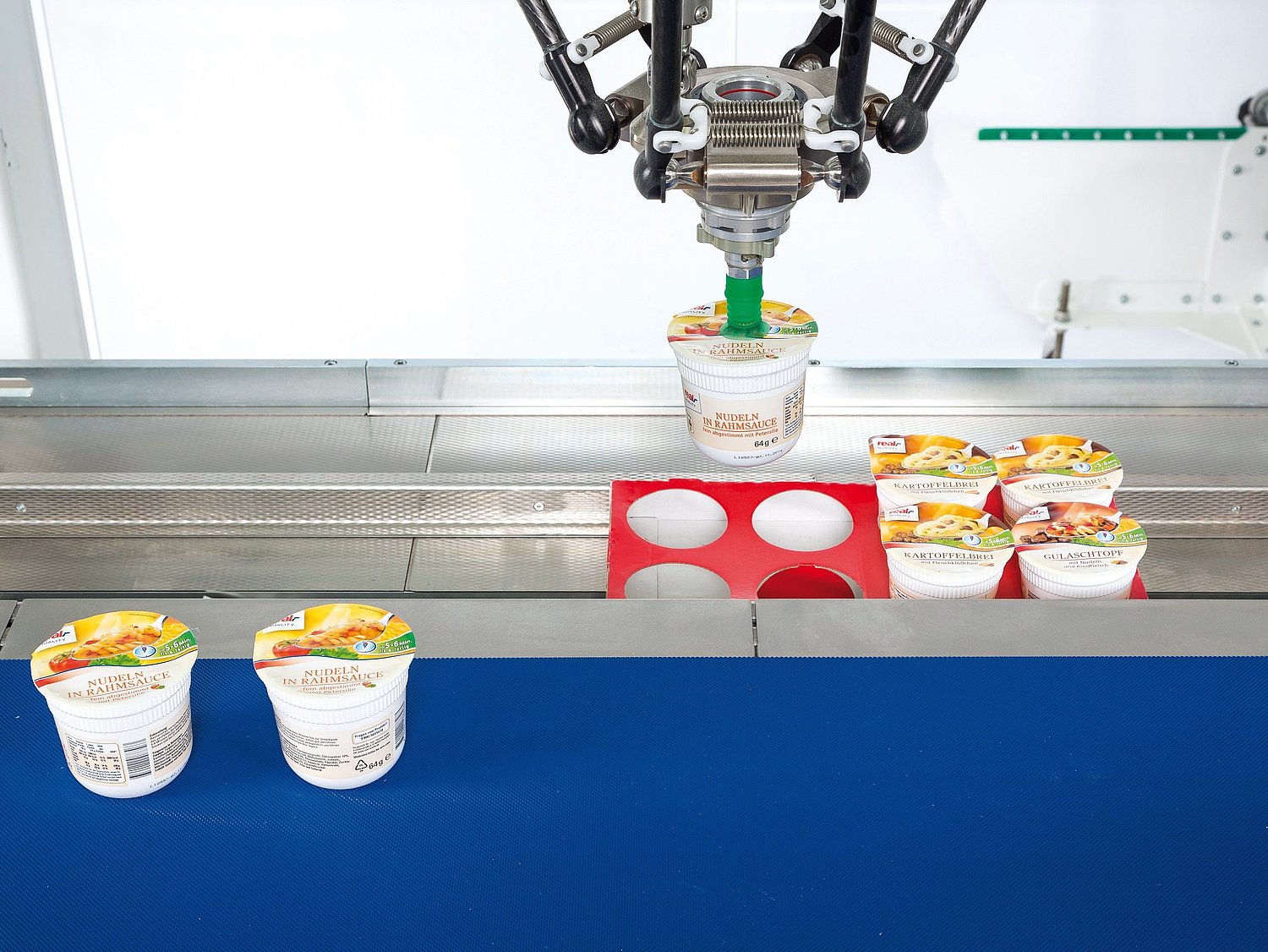

AUTOMATION – Robots and Handling SYSTEMS

Efficient and flexible automation solutions

Hugo Beck can claim a decade-long development tradition when it comes to automation. We offer support with our expertise throughout the entire automation process, from project planning and manufacture right through to integration into complex packaging lines. Handling systems such as portals, grouping solutions, stacking and counting devices, cross pusher to name but a few, are integrated reliably into the packaging solutions by our technicians.

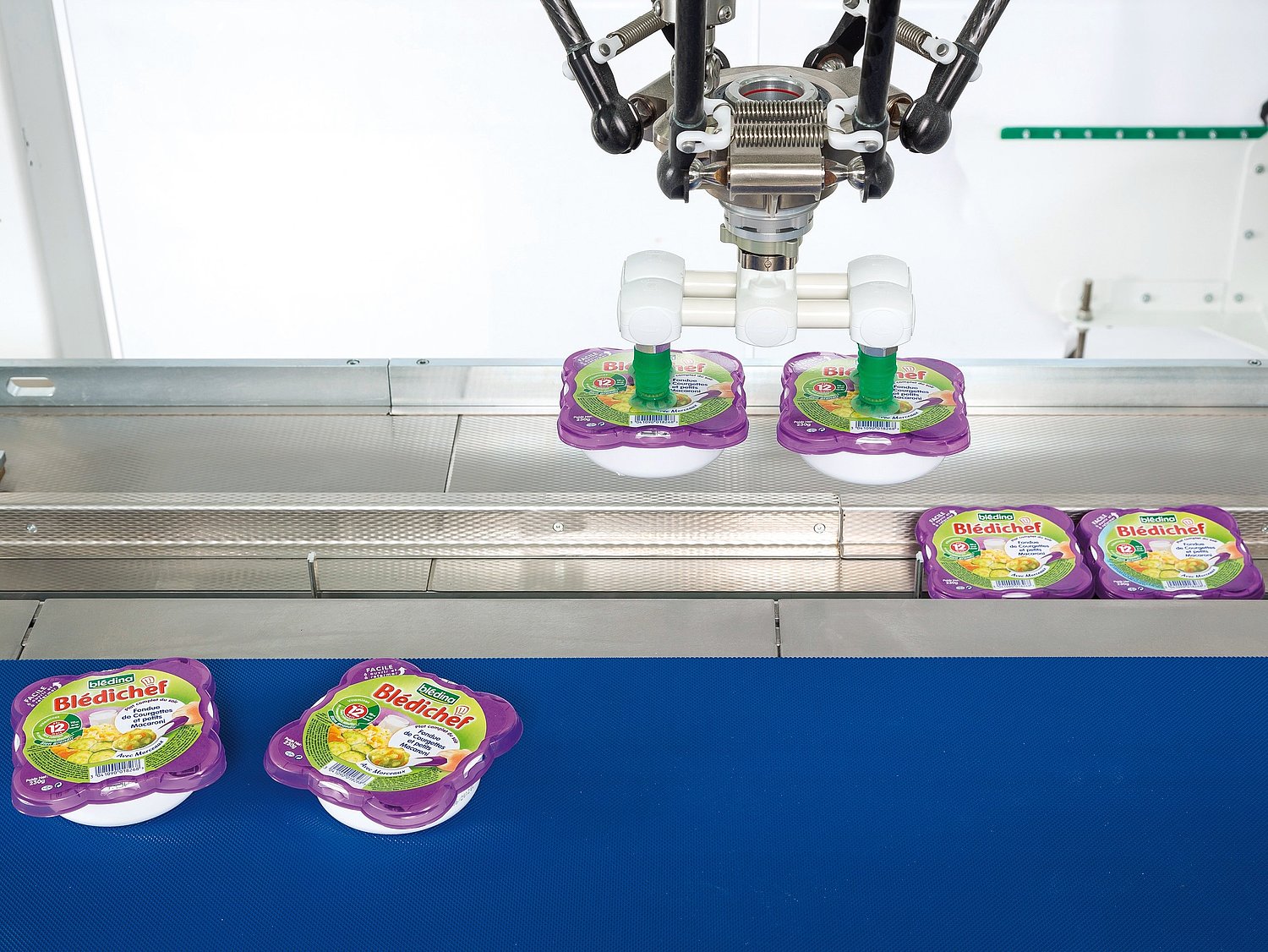

Furthermore, various robots’ systems are used across many industries for the automated feeding of products, helping to for example grip, position, stack, group, stage products. From a parallel robot (also known as a spider robot) all the way through to a SCARA robot – anything is flexibly possible and delivered fully integrated according to each customer ‘s needs.

Both robots and handling systems can all be purchased independently of Hugo Beck packaging machines.

Benefits

- Complete solutions from a single source

- Flexible technology options

- Customised handling systems

- Integration of robot systems from a variety of manufacturers

- Integration into existing and projected packaging lines