Shrink Film

SEALED AIR® Shrink Films – Durable, Efficient, and Sustainable

SEALED AIR® and CRYOVAC® shrink films offer exceptional strength, designed to protect products of all sizes, from large goods to smaller parcels. These films provide enhanced seal strength and outperform thicker materials, ensuring product safety while reducing raw material use and energy consumption.

CRYOVAC® Shrink Films

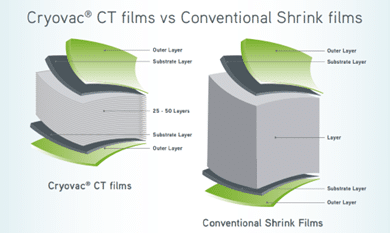

Patented CRYOVAC® brand multi-purpose shrink films deliver outstanding shrinkage, strength, and merchandise appeal, all while reducing material usage without sacrificing performance. The CRYOVAC® brand CT series films are advanced, incorporating up to 50 discrete micro-layers, compared to traditional shrink films, which typically contain just one to five layers.

These shrink films offer exceptional high-abuse properties, along with the added benefit of up to 50% reduction in packaging weight, providing a more efficient and sustainable packaging solution.

Features and Benefits

- Enhanced Merchandising Appeal: Boosts product presentation for a more attractive display.

- Outstanding Resistance: Provides superior protection for products during handling and distribution.

- Pack Integrity: Ensures products are fully wrapped, maintaining their integrity.

- Higher Productivity: Longer rolls result in fewer changeovers and less roll handling, increasing equipment uptime.

- Lower Carbon Footprint: Reduced material use and significant source reduction contribute to a more sustainable packaging solution.

CT Series Film

Cryovac® CT series of films provides a radical new technological capability within the packaging industry. This patented innovation incorporates up to 50 discrete micro- layers compared to conventional shrink films, which are typically comprised of 1, 3 or 5 layers.

Cryovac® CT range of films provide unique high abuse properties and enhanced performance compared to significantly thicker conventional shrink films, with a 30% to 50% packaging weight reduction. This weight reduction directly translates to less raw materials and energy consumed, and a reduced number of packaging supplies to provide an enhanced sustainability.

REDUCE OVERALL PACKAGING COSTS

Longer rolls results in:

- Fewer change overs and less roll handling

- Higher productivity

- Increased equipment uptime

- Improved labour utilisation

Better sealing results in:

- Fewer claims

- Better protection

- Safe storage and handling

| CT FILM | GAUGE | AVAILABLE WIDTHS (mm) |

| CT303 1905m | 10.7µm | 255, 305, 355, 405, 460, 510, 560, 660, 710, 785 |

| CT304 1454m | 14µm | 255, 305, 355, 405, 460, 510, 560, 660, 710, 785 |

| CT305 1143m | 17.8µm | 255, 305, 355, 405, 460, 510, 560, 660, 710, 785 |

| CT306 888m | 23µm | 355, 405, 460, 510, 560, 660, 710, 785 |