Semi-Automatic

The Semi-Automatic Machines are designed to bring low level automation into the production environment. A high level of flexibility is offered by the portability of the machines enabling them to be moved from one production line to another. This is combined with the option to incorporate a modified atmosphere (MAP) into the pack as well as simplicity of use and very quick and easy tooling changeovers.

Some machines within this range are fully electric and incorporate POWERDRIVE technology, therefore eliminating the requirement for a compressed air supply making them really versatile.

The Eclipse 182 is a semi-automatic, two station, rotary table tray sealer. It can be used to seal reel fed film or pre-cut lids to pre-formed trays. It can be configured to use MAP-F gas flushing (with the option of high oxygen) for extended shelf life.

Dependant on the tray size and packing mode it can seal four plus packs at a time giving a maximum output of 40 packs per minute. Compressed air and electric supply is required for this machine.

Technical Specifications:

| eclipse 182 Specifications | |

| Height | 1771mm |

| Width | 1407mm |

| Depth | 1071mm |

| Electrical Supply | 16A 240V 1 Phase N+E 10A max/phase 50/60Hz |

| Pneumatic Supply | 7.75cfm at 80psi (5.5 bar) |

Features:

Efficient

- User-friendly high clarity HMI touch screen

- Interactive HMI with operator prompts

- Accurate monitor temperature control

Intelligent

- Automatic recipe driven film set up

- Film snap protection

- Easy to follow guided film path for loading

- Self-diagnostic

- Interactive screen: coder can be controlled through the machine HMI

- Servo controlled film feed ensures foil film on a roll can be sealed to trays

- Remote access solution for remote diagnostics and program updates

- SQL data logger

Future Proofed

- Atmospheric sealing

- MAP-F (Gas Flushing)

- Fully portable with fixed locking feet

- Date coder integration ready

Hygienic

- Fully hygienic, robust construction to food industry standards

- Full open access with interlocked guarding and open construction machine bed for hygiene

Flexible Tooling

- Two-minute tool changeover

- Quick release tools

- Inbuilt tool docking system aligns electrical and gas connectors

- Lightweight tooling

- Quick release cutting blades

- Waterproof heater mats, rapid warm up times

- Eco-cut film saving tooling options Inside-cut & foil crimping functions

- Capability to seal pots/trays up to 120mm deep

Packaging Materials:

- Plastic trays

PP, A-PET, C-PET, R-PET,

- Plant based bioplastic trays

Polylactic Acid (PLA)

- Foil trays

Smooth Wall Foil Trays

- Pulp and Board trays

Pressed, Folded or Pulp Trays

- Lidding materials

Reel-fed Plastic Film and Foil

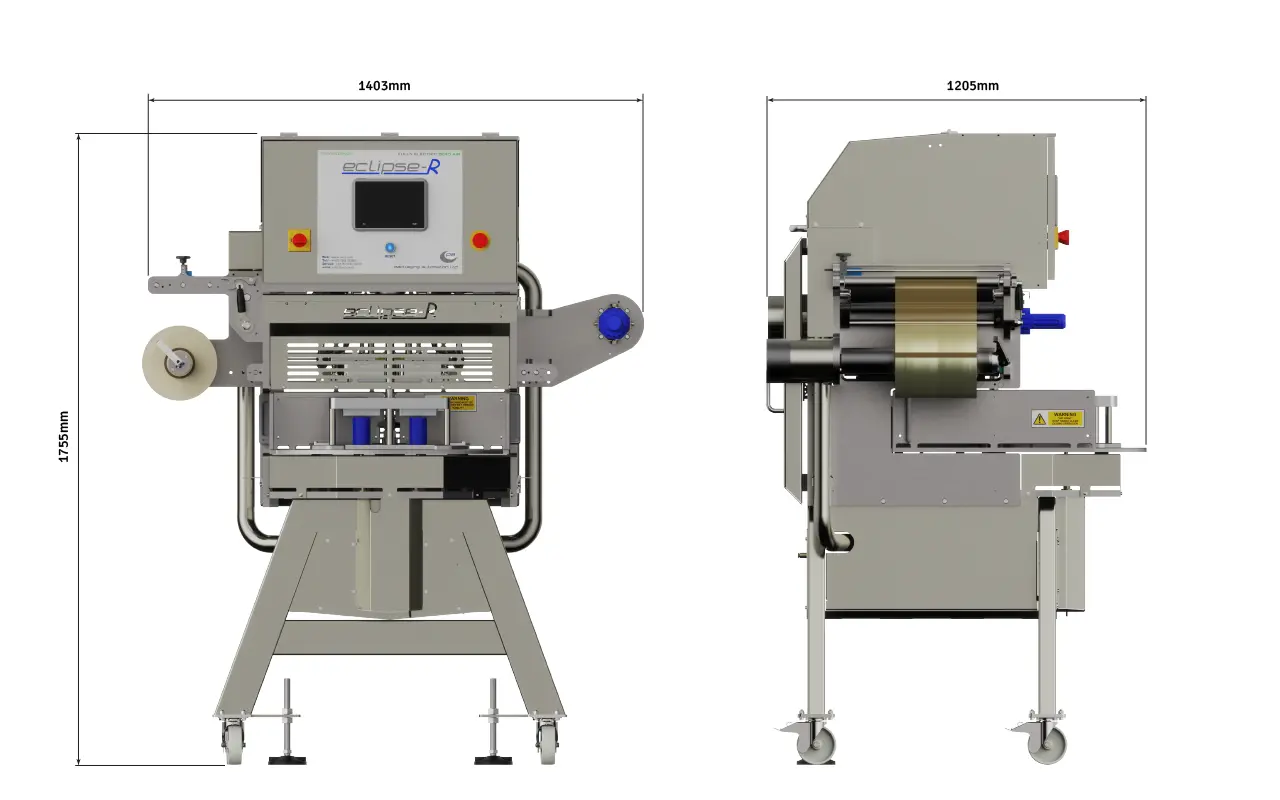

The Eclipse R fully electric, semi-automatic, two station, rotary table tray sealer.

Incorporating POWERDRIVE technology, there is no requirement for a compressed air supply. It can be configured to have an automatically rotating table to reduce operator strain.

The Eclipse R can be used to seal reel fed film or pre-cut lids to pre-formed trays. It can be configured to use MAP-F gas flushing (with the option of high oxygen) for extended shelf life.

Dependent on the tray size and packing mode it can seal four plus packs at a time giving a maximum output of 40 packs per minute. Electric supply only is required for this machine.

Technical Specifications:

| eclipse R Specifications | |

| Height | 1755mm |

| Width | 1403mm |

| Depth | 1205mm |

| Weight | 700kg |

| Electrical Supply | 16A 415V 1 Phase N+E 10A max/phase 50/60Hz |

| Pneumatic Supply | Not Required |

Features:

Efficient

- User-friendly high clarity HMI touch screen

- Interactive HMI with operator prompts

- Accurate monitor temperature control

Intelligent

- Automatic recipe driven film set up

- Film snap protection

- Easy to follow guided film path for loading

- Self-diagnostic

- Interactive screen: coder can be controlled through the machine HMI

- Servo controlled film feed ensures foil film on a roll can be sealed to trays

- Remote access solution for remote diagnostics and program updates

- SQL data logger

Future Proofed

- Atmospheric sealing

- MAP-F (Gas Flushing)

- Fully portable with fixed locking feet

- Date coder integration ready

Hygienic

- Fully hygienic, robust construction to food industry standards

- Full open access with interlocked guarding and open construction machine bed for hygiene

Flexible Tooling

- Two-minute tool changeover

- Quick release tools

- Inbuilt tool docking system aligns electrical and gas connectors

- Lightweight tooling

- Quick release cutting blades

- Waterproof heater mats, rapid warm up times

- Eco-cut film saving tooling options Inside-cut & foil crimping functions

- Capability to seal pots/trays up to 120mm deep

Packaging Materials:

- Plastic trays

PP, A-PET, C-PET, R-PET,

- Plant based bioplastic trays

Polylactic Acid (PLA)

- Foil trays

Smooth Wall Foil Trays

- Pulp and Board trays

Pressed, Folded or Pulp Trays

- Lidding materials

Reel-fed Plastic Film and Foil

The Eclipse 2016 is a two station, rotary table tray sealer with fully automatic rotation of the table and full MAP-V vacuum capability. It can be used to seal reel fed film or pre-cut lids (in atmospheric sealing mode only) to pre-formed trays.

Dependant on the tray size it can seal up to four packs at a time giving a maximum output of 40 packs per minute when in MAP-V mode. Compressed air and electric supply is required for this machine.

Technical Specifications:

| eclipse 2016 Specifications | |

| Height | 1870mm |

| Width | 1175mm |

| Depth | 1455mm |

| Electrical Supply | 20A 415V 3 Phase N+E 8A max/phase 50/60Hz |

| Pneumatic Supply | 8cfm at 80psi |

Features:

Energy Saving

- Automatic standby mode when not in use

- Reduced gas consumption with MAP sealing

Efficient

- User-friendly high clarity HMI touch screen

- Interactive HMI with operator prompts

- Accurate monitor temperature control

- MAP-V version includes integrated machine mounted 55m3 vacuum pump.

Intelligent

- Automatic recipe driven film set up

- Film snap protection

- Easy to follow guided film path for loading

- Intelligent self-diagnosis system

- Interactive screen: coder can be controlled through the machine HMI

- Servo controlled film feed ensures foil trays can be sealed with reel fed film

- Remote access solution for remote diagnostics and program updates

- SQL data logger

Future Proofed

- Atmospheric sealing

- MAP-F (Gas Flushing)

- Fully portable with fixed locking feet

- Date coder integration ready

Hygienic

- Fully hygienic, robust construction to food industry standards

- Full open access with interlocked guarding and open construction machine bed for hygiene

Flexible Tooling

- Four-minute tool changeover

- Quick release tools

- Inbuilt tool docking system aligns electrical and gas connectors

- Lightweight tooling

- Quick release cutting blades

- Waterproof heater mats, rapid warm up times

- Eco -Cut film saving tooling options

- Inside-cut and foil crimping functions

- Capability to seal pots/trays up to 140mm deep

Packaging Materials:

- Plastic trays

PP, A-PET, C-PET, R-PET,

- Plant based bioplastic trays

Polylactic Acid (PLA)

- Foil trays

Smooth Wall Foil Trays

- Pulp and Board trays

Pressed, Folded or Pulp Trays

- Lidding materials

Reel-fed Plastic Film and Foil