Rotofill (Pot Filling Closing | Pot Filling Machines | Rotofill | Rotofill | Packaging Automation Ltd)

The Rotofill is a flexible high speed rotary filling and closing machine incorporating servo technology. It can be used to seal pre-cut lids or reel fed film with clip on overcaps or a range of tamper evident closures.

Integration with a wide range of fillers is offered as standard giving an extremely versatile solution with up to three pots filled and sealed at a time.

Production speeds are dependent on the pot size, product consistency, fill volume and closure type but can be up to 120 pots per minute.

Technical Specifications:

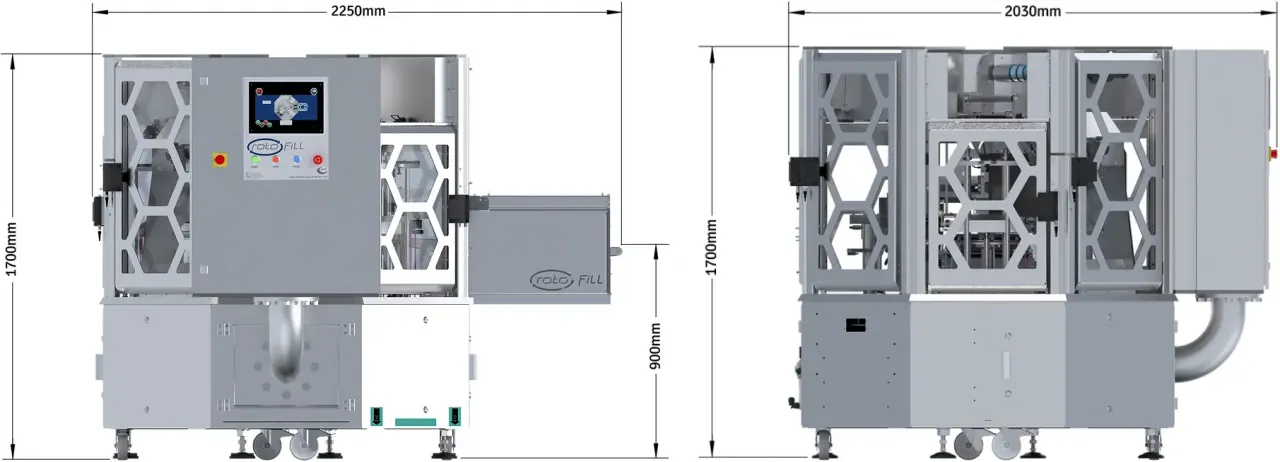

| Rotofill Specifications | |

| Height | 1700mm |

| Width | 2250mm |

| Depth | 2030mm |

| Electrical Supply | 32A 415V 3 Phase N+E 16A max/phase 50/60Hz |

| Pneumatic Supply | 17cfm or 500 litres/min 80psi (5.5bar) |

Features:

Machine Features

- User friendly

- Mounted on casters for easy mobility

- Servo controlled table for smooth indexing

- An integrated setup wizard walks the operator through tool changes step by step, simplifying and deskilling the process

- Highly intuitive touch screen provides user friendly operation with real time feedback and instructions, meaning greater reliability and reduced downtime

- Automatic height adjusting pot dispenser removes the need for operator setup allowing for different depths of pots on the same change parts

- High speed laser pot detection

- Servo driven intelligent pre-cut lid pick and place

- Built in lid detection with multiple retry options

- Recipe controlled Servo Fill option

- Highly accurate heater control system

- A single point cable entry on the main cubicle ensures IP66 rating is maintained

- LED status technology on guard switch

- Increased storage under machine bed

- Single piece stainless steel table to aid with machine hygiene

- Quick release removable hygienic eject conveyor

- Cleverly designed guarding for complete wash down access

- Torque monitoring and torque limiting functions alert operator to problems before they arise

- Sale, lease purchase and rental options tailored to suit all requirements

Change Parts

- Simple, lightweight change parts

- Quick release, tool less operation

- Precision change parts produce an accurate film cut with profiled peel tabs if required

- Ultimate sealing flexibility, single, dual and triple impression options

- Colour anodising options can be supplied to aid identification

- Quick release sealing head with built-in fail safe locator to prevent incorrect removal

- The tool is connected by a robust plug and socket. The single point connection simplifies loading and unloading of the tool.

- In-built fail safe eject mechanism to ensure successful discharge of packaging

- Table inserts simply locate each pot and are easily interchangeable for alternative change parts

- Pre-cut lid or reel fed options

- Pre-set, accurate dowels enable fast locating mechanical interface

- Interchangeable nozzles and pump tubes for differing product types

- Time saving self-centralising dowels locate the de-nester and lid pick and place assemblies simplifying changeovers

Options

- Reel stock film feed with automatic rewind film waste. Full servo control with integrated continuous torque monitoring (CMT) provides precise film tension control – synchronised with table movement

- Film registration option for printed film

- MAP-F (Modified Atmosphere Packaging)

- Servo driven over cap applier with built-in presence detection and multiple retry option

- Date coder integration ready

- Flexibility in guarding – option laser cut stainless steel vs polycarbonate cartridges for improved visibility

- Rotary accumulation table

- Can be integrated with additional dry product filling equipment

- Industrial remote access solution for remote diagnostics and program updates

- Change part storage

Materials

The Rotofill has the ability to heat seal reel fed film, pre-cut foil, paper or laminate lids to preformed trays and containers of CPET, Polypropylene, PVC, Styrene, Board, Smooth walled foil, pre-cut board, Paper, Plastic, and many other types of container.

Rotofill Filler Options

- Seamless integration of 3rd party fillers (wet or dry)

- Pre-filled stations for layered products

- Double skinned tanks for hot products

- Hot product fill nozzle and piston parts

- Interchangeable nozzle types

- Product tank agitation

- Tank temperature probe for accurate product temperatures

- Tank level probe for automatic fill

Packaging Material:

- Plastic trays

PP, A-PET, C-PET, R-PET, PS

- Pulp and Board trays

Pre-cut board or pulp trays

- Lidding materials

Film lidding material on a reel

Pre-cut foil, paper or laminate lids