Label Serialisation

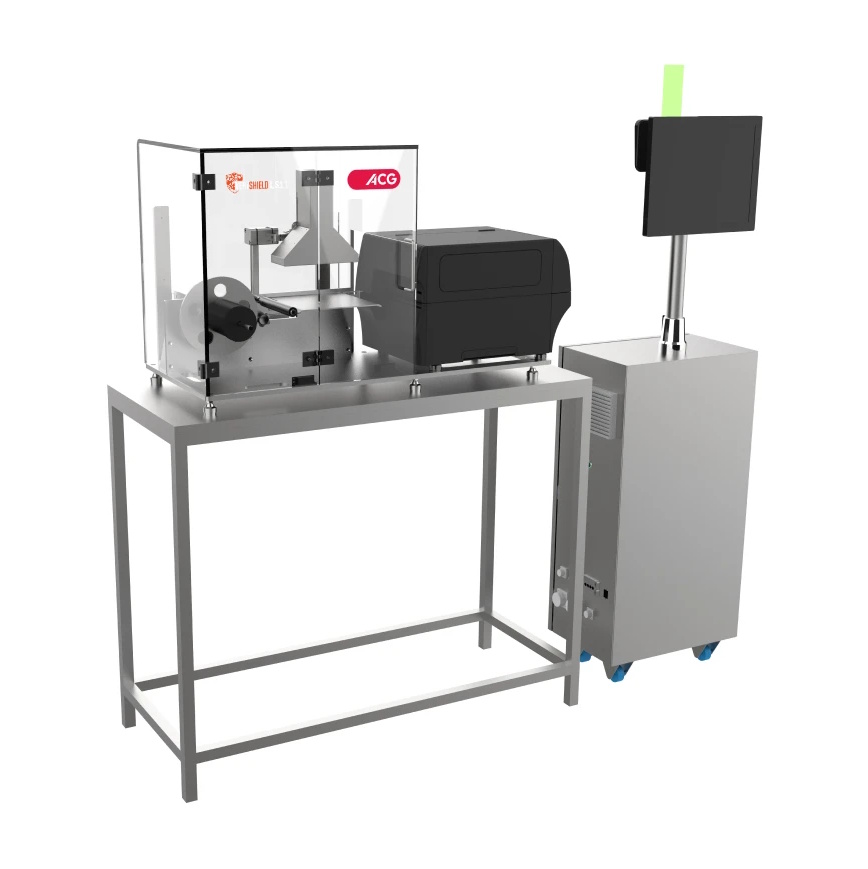

VERISHIELD LS series

The VERISHIELD LS series is designed to uniquely identify and serialise labels, providing a comprehensive solution for product authentication, traceability, and supply chain security.

The VERISHIELD LS series is designed to uniquely identify and serialise labels, providing a comprehensive solution for product authentication, traceability, and supply chain security.

VERISHIELD LS11 is our label serialisation system for online printing and inspection of labels.

Functionality

Online label print and inspect

| Features | Benefits | |

|---|---|---|

| In-line label printing and inspection functionality |  |

Can be seamlessly integrated with existing bottling line for serialisation |

| High-speed machine with a compact design |  |

Requires minimal time floor space and time |

| Supports track and trace regulations of multiple countries |  |

A single machine that fulfils diverse requirements of different regulations |

| Plug and play compatibility with bottling line |  |

User-friendly interface for operation and maintenance activities

Can be integrated on existing bottling line equipment for serialisation functionality |

Technical specifications

| Maximum throughput |

120 products/min |

| Field of view (FOV) |

50 mm x 25 mm |

| Rejection system |

Encoder-based rejection system with pneumatic cylinder and rejection bin |

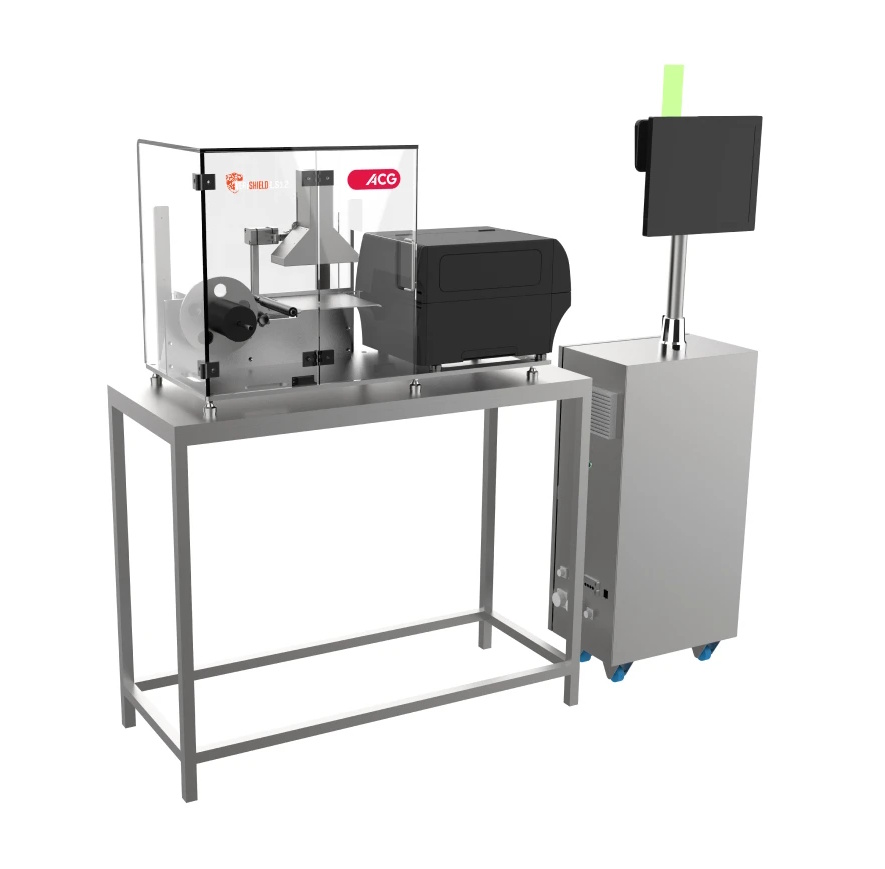

The VERISHIELD LS series is designed to uniquely identify and serialise labels, providing a comprehensive solution for product authentication, traceability, and supply chain security.

LS12 is a stand-alone carton serialisation system for inspection, and rejection of labels with defective print.

Functionality

Online print, inspect and reject with winder

| Features | Benefits | |

|---|---|---|

| Stand-alone label printing, inspection and rejection functionality |  |

Suitable for low volume production facilities |

| High-speed machine with a compact design |  |

Requires minimal time floor space and time |

| Supports track and trace regulations of multiple countries |  |

A single machine that fulfils diverse requirements of different regulations |

| EU Annex 11 and FDA 21 CFR Part 11 compliant |  |

A regulatory-compliant, audit-friendly system |

Technical specifications

| Maximum throughput |

12 labels/min |

| Rejection system |

Machine stop |