IPA Roller Compactor

Innovative Process Applications (IPA) is known for designing and manufacturing some of the highest quality roller compaction systems in the industry. Their equipment is widely used in industrial, nutraceutical, and pharmaceutical dry granulation applications, offering reliable performance and flexible design.

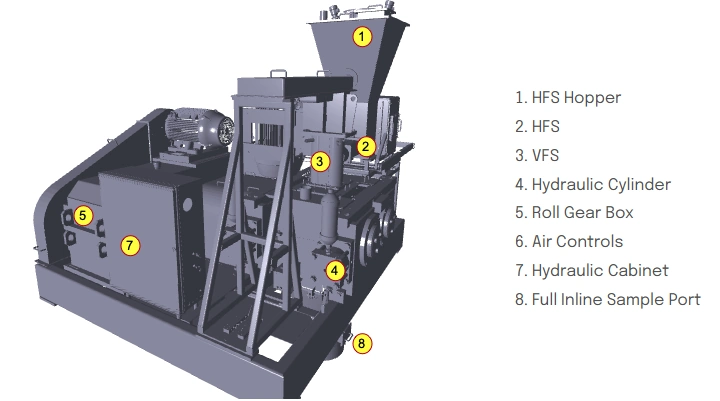

IPA’s roller compactors feature a twin feed screw system, similar to the Fitzpatrick Chilsonator, with the advantage of independent control over feed rate and deaeration. This design helps manage system throughput and pre-compression separately, allowing for greater precision. The twin feed screw also helps maintain lower operating temperatures, making it perfect for processing materials with lighter bulk density and high air content.

Each IPA Roll Compaction System is delivered as a complete solution, including a roller compactor, mill, screener, and elevator or conveyor. The system’s custom PLC controls can easily connect with both upstream and downstream equipment and can integrate with local DCS networks. IPA offers unit sizes to suit a wide range of production rates, from 100 kgs/hr to 5000 kgs/hr, depending on product density and yield.

What sets IPA apart is their hands-on, collaborative approach. They work closely with customer engineering teams to customize every system component for the specific application. IPA’s dedicated team also provides ongoing support and aftermarket services to ensure long-term, efficient system performance.

IPA is committed to delivering not just quality machines, but also tailored solutions that help customers achieve the best results.

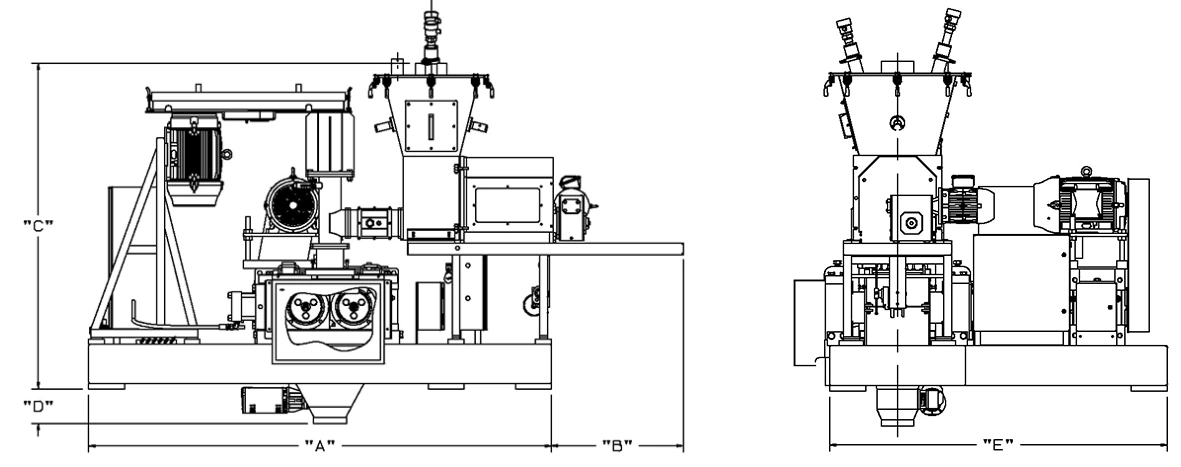

Overall Dimensions (Inches) |

||||||

|---|---|---|---|---|---|---|

| Machine Size | “A” | “B” | “C” | “D” | “E” | Weight (lbs) |

| 4×10 | 82 | 24 | 59 | 5-1/2 | 70 | 6,200 |

| 7×10 | 90 | 24-3/4 | 62-1/4 | 10-1/2 | 71 | 6,900 |

| 8×12 | 111-1/2 | 28-1/4 | 79-3/16 | 9-1/8 | 77 | 9,600 |

| 12×12 | 116-1/2 | 33-1/4 | 81-7/8 | 8-3/4 | 84 | 20,000 |

| 12×16 | 117 | 32-1/4 | 98-1/4 | 13 | 88 | 18,700 |

| 12×20 | 126 | 27-3/4 | 100 | 14 | 105 | 24,000 |

| 16×20 | 133 | 41 | 108-1/2 | 12-3/4 | 104 | 25,600 |