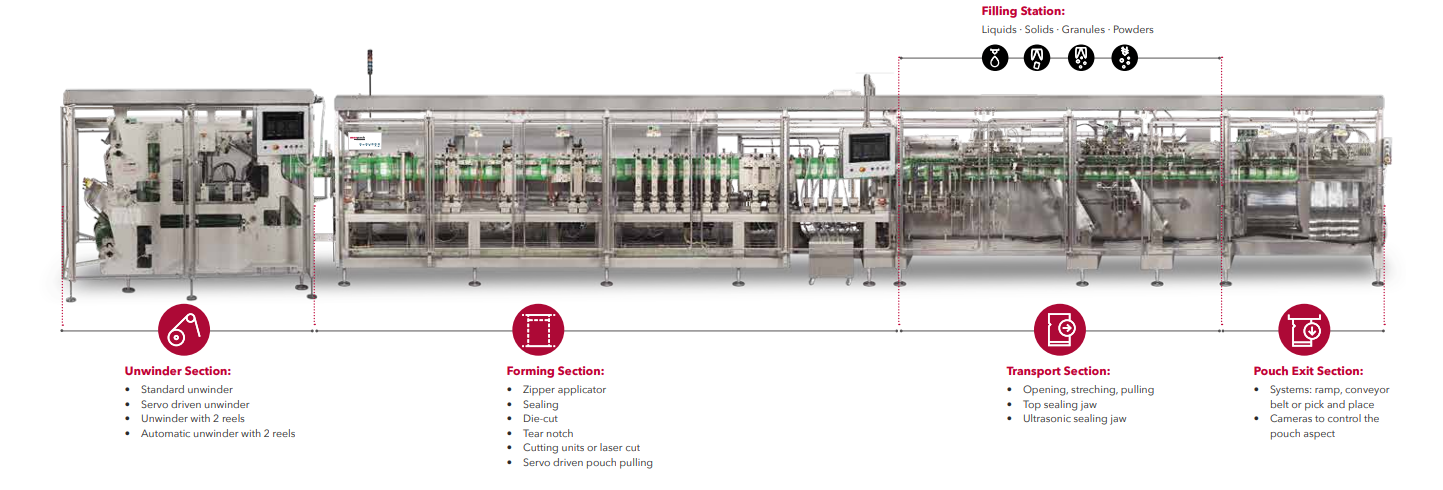

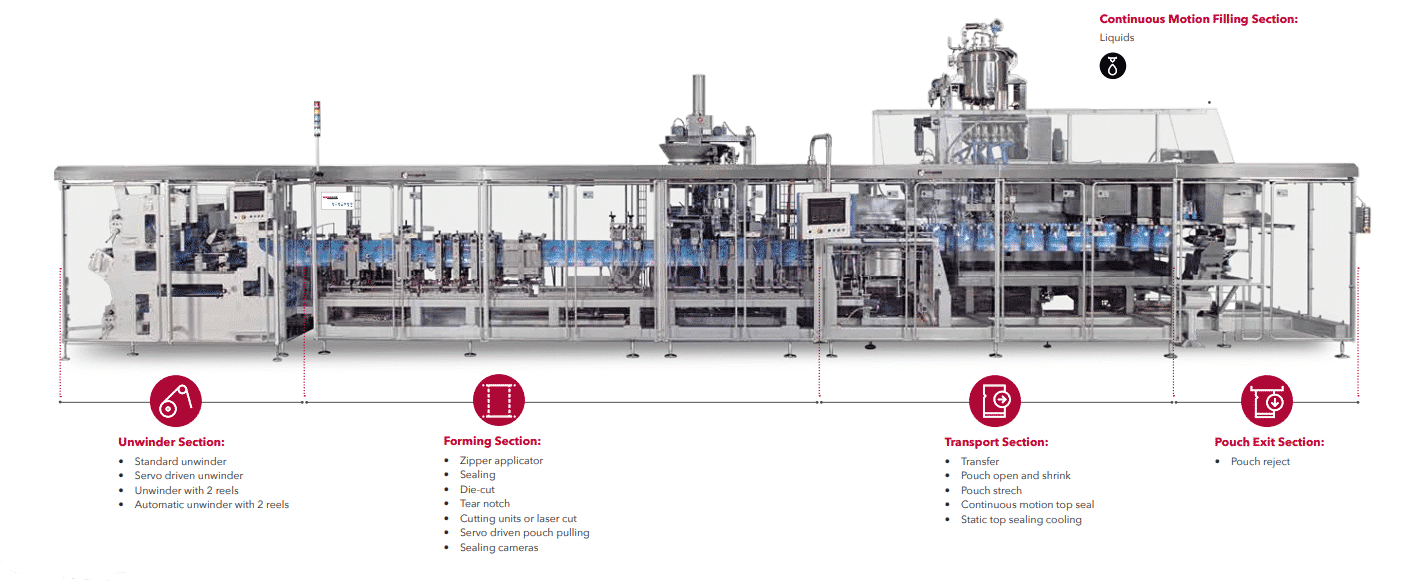

Horizontal Form Fill and Seal

MODELS H640, H570, H540, H440, H420, H380, H360, H330, H320, H280, H260, H220, H180, H170, H150, H145, H140, H130, H100.

Main Standard Features

→ 18.5” color touch screen

→ Independent unwind system with autosplice features (optional)

→ Automatic adjustment control of seal jaws position (optional)

→ Automatic hole punch correction system for stand up pouches

→ Servo driven change over system for plough formation

→ 3 to 5 different filling stations

→ Cam driven walking beam (for big formats)

→ Static pouch stretching prior to sealing

→ Pouch reject station

→ PLC automatic lubrication system (optional)

→ Roller servo driven stroke indexing system

→ Ultra-clean versions (optional)

→ Laser, inkjet or printer coder (optional)

→ ATEX compliance (optional)

→ Film sterilization system (optional)

→ Laminar flow (optional)

→ MAP (Modified Atmosphere Packaging) Ultrasonic sealing (optional)

→ Ultrasonic sealing (optional)

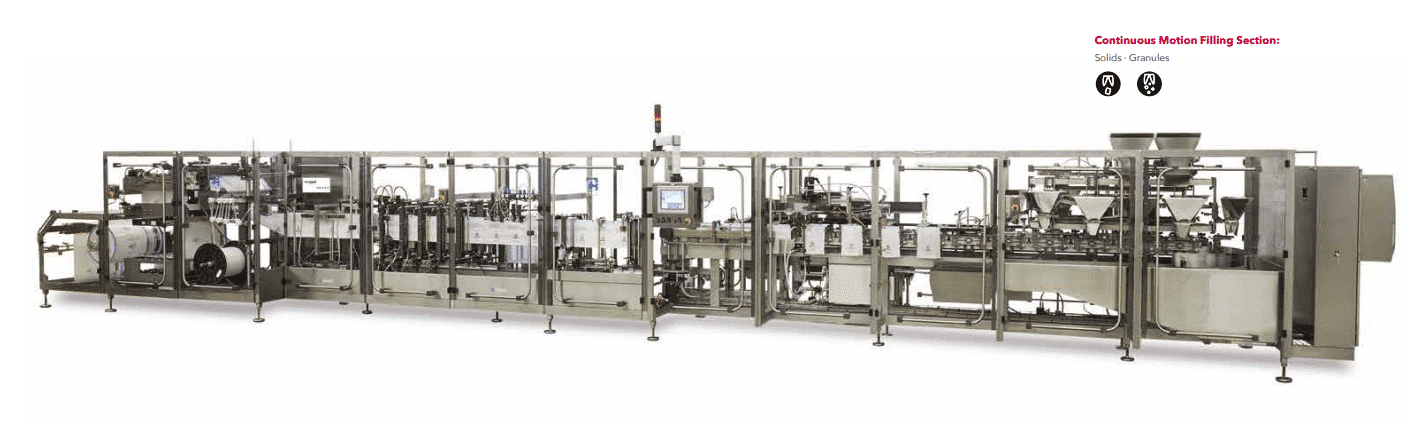

MODELS HCRM640, HCM420

Main Standard Features

→ 18.5” color touch screen

→ Independent unwind system with autosplice features (optional)

→ Automatic adjustment control of seal jaws position (optional)

→ Automatic hole punch correction system for stand up pouches

→ Servo driven change over system for forming plough

→ Triple pouch opening system through vacuum, air jet & mechanical device

→ Pouch reject station

→ PLC automatic lubrication system

→ Roller servo driven stroke indexing system

→ Ultraclean versions (optional)

→ Laser coders and scorers (optional)

→ ATEX compliance (optional)

→ Film sterilization system (optional)

→ Laminar flow (optional)

→ M.A.P. (Modified Atmosphere Packaging)

→ Ultrasonic sealing (optional)

MODELS CMR1500, CMR1250, CMRII

Main Standard Features

→ 18.5” color touch screen

→ Independent unwind system with autosplice features (optional)

→ Automatic adjustment control of seal jaws position (optional)

→ Automatic hole punch correction system for stand up pouches

→ Servo driven change over system for forming plough

→ Triple pouch opening system through vacuum, air jet & mechanical device

→ Pouch reject station

→ PLC automatic lubrication system

→ Roller servo driven stroke indexing system

→ Ultraclean versions (optional)

→ Laser coders and scorers (optional)

→ ATEX compliance (optional)

→ Film sterilization system (optional)

→ Laminar flow (optional)

→ M.A.P. (Modified Atmosphere Packaging)

→ Ultrasonic sealing (optional)

MODELS HCRM660

Main standard features

- Athena enabled (HMI and IIoT)

- Automatic adjustment seal jaws position

- Automatic bottom perforator correction system for stand-up pouches

- Autosplice unwinder

- Maximum of 3 filling stations

- PLC automatic lubrication system.

- Pouch reject station

- Quick Changeover

- Recyclable ready films

- Servo height Adjustable triangle

- Servomotor pulling

- Static pouch stretching prior to top sealing

* Some of the items listed are optional

MODELS HIM570

Main Standard Features

→ 18.5” color touch screen

→ Independent unwind system with autosplice features (optional)

→ Automatic adjustment control of seal jaws position (optional)

→ Automatic hole punch correction system for stand up pouches

→ Servo driven changeover system for forming plough

→ Triple pouch opening system through vacuum,

air jet & mechanical device

→ Pouch reject station

→ PLC automatic lubrication system

→ Roller servo driven stroke indexing system

→ Ultraclean versions (optional)

→ Laser coders and scorers (optional)

→ ATEX compliance (optional)

→ Film sterilization system (optional)

→ Laminar flow (optional)

→ M.A.P. (Modified Atmosphere Packaging)

→ Ultrasonic sealing (optional)