Fully Automatic

The Fully Automatic Machines offer a cost-effective medium capacity option to those with a requirement to cut labour costs through the automation of a packing line. Designed for frequent product changeovers, flexibility is offered with tool changes in minutes and recipe driven set up.

Some machines within this range are fully electric and incorporate POWERDRIVE technology, therefore eliminating the requirement for a compressed air supply and can be integrated into any existing or new line.

MAP (Modified atmosphere packaging) as well as SkinPAC are options on these machines.

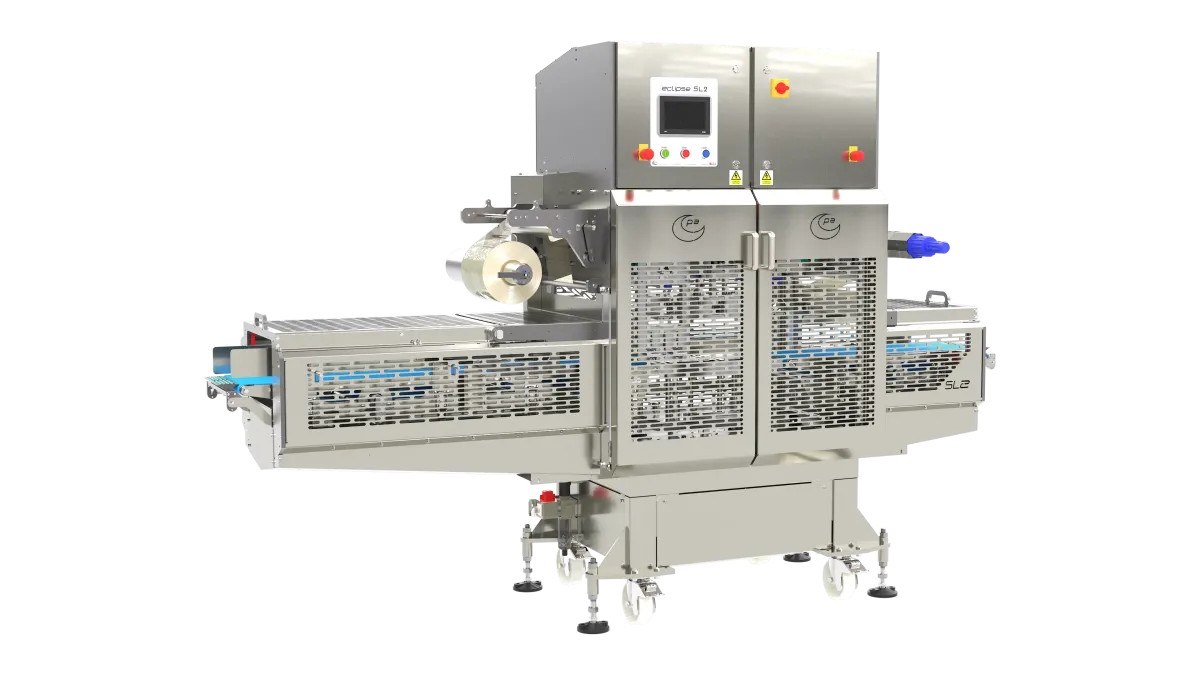

The Eclipse SL2 is the entry level automatic tray sealer combining medium speed output with quick tool changes and a compact space saving design. It can be used to seal reel fed film to pre-formed trays and can be configured to use MAP-F gas flushing for extended shelf life.

Dependant on the tray size and packing mode it can seal up to 3 packs at a time giving a maximum output of 54 packs per minute.

The Eclipse SL2 is designed to accommodate the top and base tools from the EC182 machine to provide a cost-effective transition to automation from semi-automatic tray sealing. Compressed air and electric supply is required for this machine.

Technical Specifications:

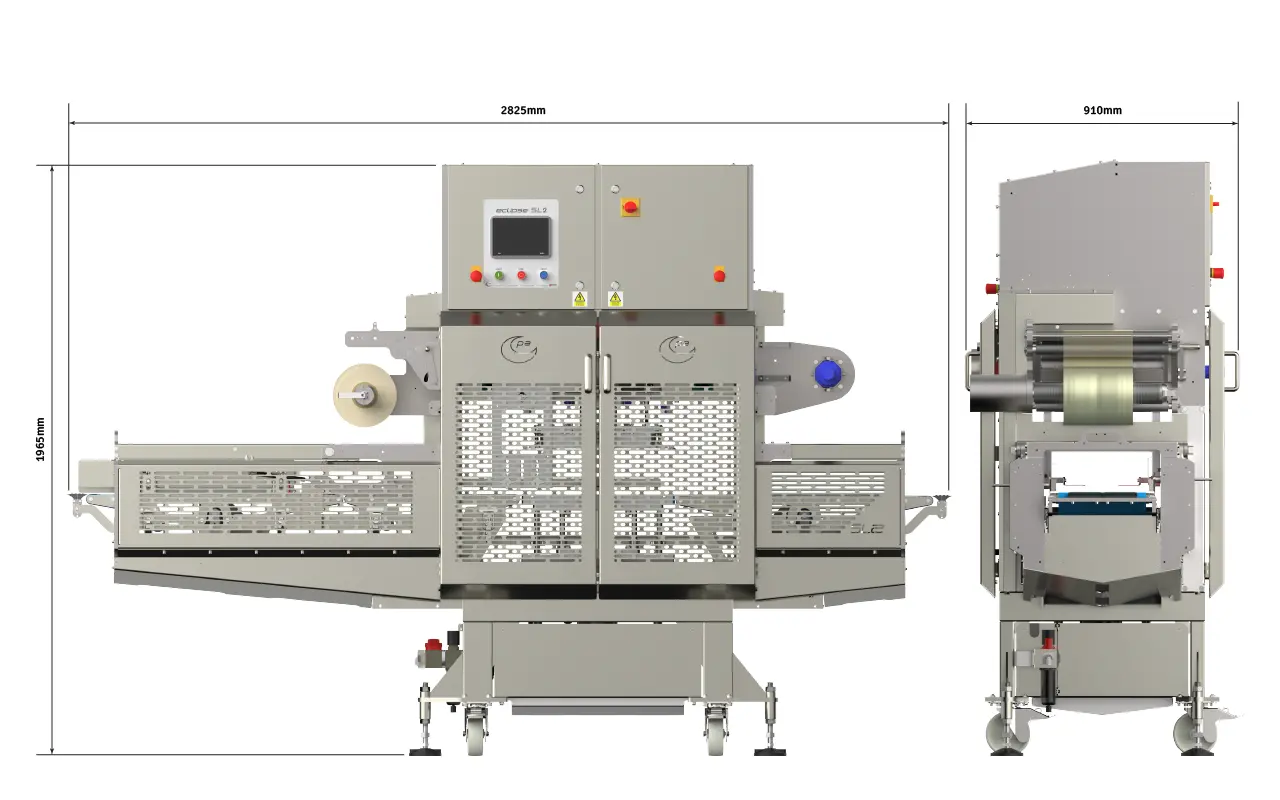

| eclipse SL2 Specifications | |

| Height | 1965mm |

| Width | 2825mm |

| Depth | 910mm |

| Electrical Supply | 16A 415V 3 Phase N+E 15A max/phase 50/60Hz |

| Pneumatic Supply | 7.75cfm at 80psi (5.5bar) 16mm Push-Fit fitting |

Features:

Energy Saving

- Automatic standby mode when not in use

- Reduced gas consumption with MAP sealing

Intelligent

- Automatic recipe driven film set up

- Film snap protection

- Easy to follow guided film path for loading

- Self-diagnostic

- Tool pack block sensor to avoid smash ups

- Pack crush protection on stepping belt

- Industrial remote access diagnosis

- Interactive screen: coder can be controlled through the machine HMI

Efficient

- User-friendly high clarity 12″ HMI touch screen

- Interactive HMI with operator prompts

- Accurate monitor temperature control

- Zonal guarding protection system

Future Proofed

- Atmospheric sealing

- MAP-F (Gas Flushing)

- Fully portable with fixed locking feet

- Date coder integration ready

- Bypass/Passive conveyor available

- Industry 4.0 ready

Hygienic

- Full hygienic, robust construction to food industry standards

- Full open access with interlocked guarding and open construction machine bed for hygiene

- Quick release removable conveyors

Flexible Tooling

- POD-tech, cartridge style tooling – gives a 90% reduction in any unplanned downtime

- Can accept rotary top tools with modified bases and new transfer arms

- Two minute tool changeover

- Quick release tools

- Inbuilt tools docking system aligns electrical and gas connectors

- Lightweight tooling

- Quick release cutting blades

- Waterproof heater mats, rapid warm up times

- Eco-cut film saving tooling options

- Inside-cut and foil crimping functions

Packaging Materials:

- Plastic trays

PP, A-PET, C-PET, R-PET,

- Plant based bioplastic trays

Polylactic Acid (PLA)

- Foil trays

Smooth Wall Foil Trays

- Pulp and Board trays

Pressed, Folded or Pulp Trays

- Lidding materials

Reel-fed Plastic Film and Foil.

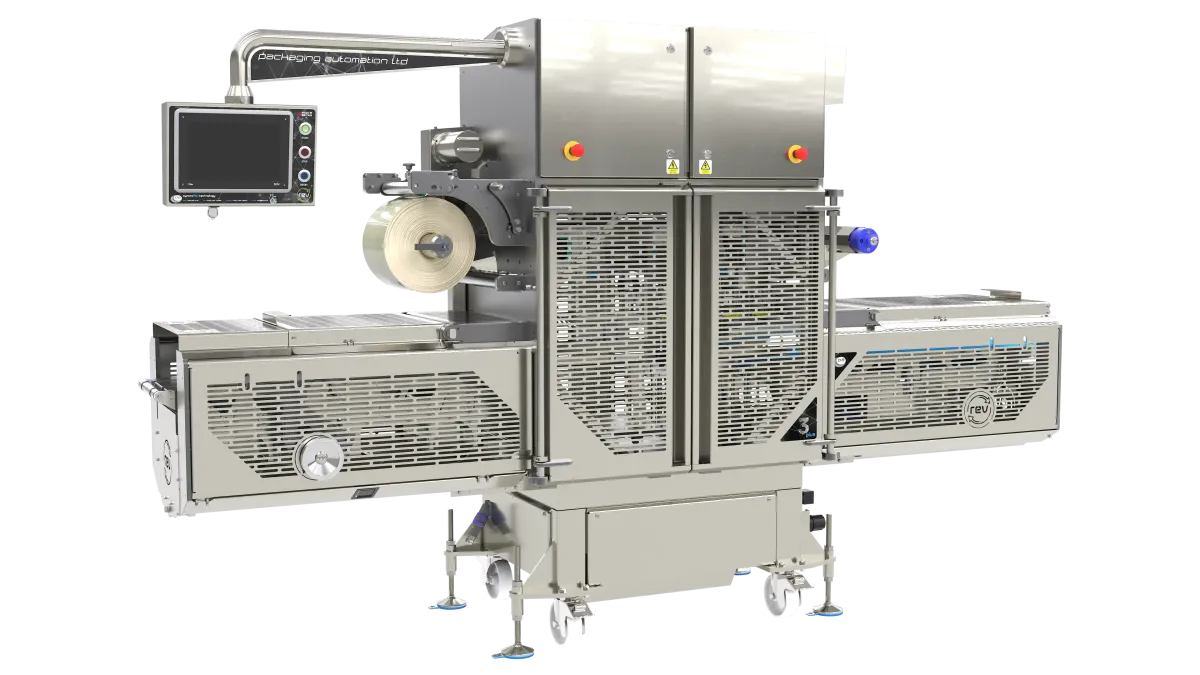

A Fully Electric Automatic Tray Sealer – where innovation meets efficiency.

The REV machines are the fastest, most energy efficient and flexible single lane tray sealers incorporating PA’s latest technology and with the REV3 a small and compact footprint. Using proven syncroflex control ensures a continuous flow of trays through the machine from infeed to outfeed, eliminating the need for any pausing or buffering. To add to its versatility it can accommodate Eclipse 182 and Eclipse R tools to aid transition from manual to automatic technology.

Technical Specifications:

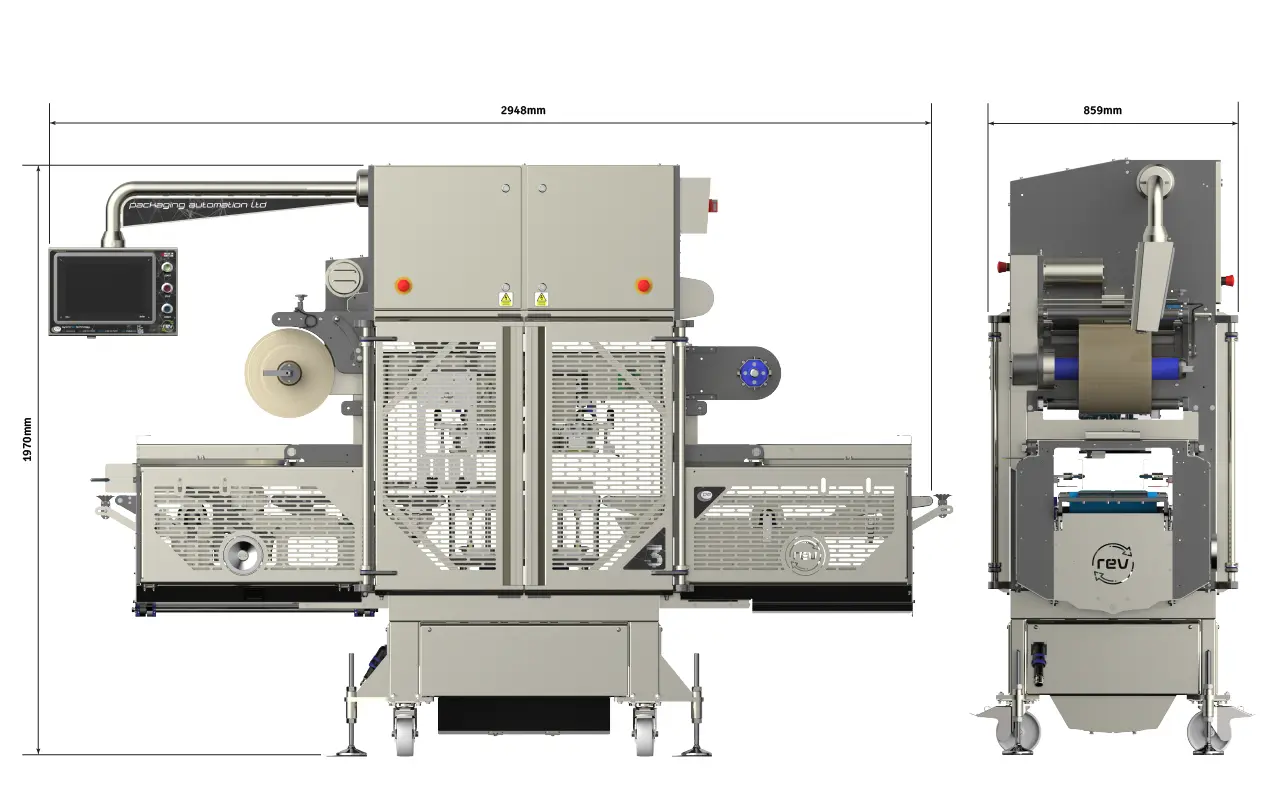

| rev3 Specifications | |

| Height | 1970mm |

| Width | 2948mm |

| Depth | 859mm |

| Electrical Supply | 16A 415V 3-Phase N+E 16A Max/Phase, 50/60Hz |

| Pneumatic Supply | N/A |

Features:

Energy Saving

- POWERDRIVE™ – fully electric – zero air

- Automatic standby mode when not in use

- Energy Reload System (ERS)

Efficient

- User-friendly high clarity HMI touch screen

- Interactive HMI with operator prompts

- Accurate monitor temperature control

Intelligent

- Automatic recipe driven film set up

- Auto adjusting film tension system

- Film snap protection

- Easy to follow guided film path for loading

- Intelligent self-diagnosis system

- Tool pack block sensor to avoid smash ups

- Pack crush protection on stepping belt

- Industrial remote access diagnosis

- Interactive screen: coder can be controlled through the machine HMI

- RFID fob access and full audit trail

- Data Connect – online data capture solution. Machine operating linear speed curves programmable for awkward products

- SQL data logger

Future Proofed

- Atmospheric sealing

- MAP-F (Gas Flushing)

- Fully operational from both sides

- Fully portable with fixed locking feet

- Small footprint design in single lane format

- Date coder integration ready

- Bypass/Passive conveyor available

- Industry 4.0 ready

Hygienic

- Full hygienic, robust construction to food industry standards

- Full open access with interlocked guarding and open construction machine bed for hygiene

- Quick release removal conveyors

Flexible Tooling

- POD-tech, cartridge style tooling – gives a 90% reduction in any unplanned downtime

- Tool-less, fast base tool locking mechanism

- Two-minute tool changeover

- Quick release tools

- Inbuilt tool docking system aligns electrical and gas/vacuum connectors

- Lightweight tooling

- Easy height-adjusting telescopic transfer arm

- Quick release cutting blades

- Waterproof heater mats, rapid warm up times

- Eco-cut film saving tooling options

- Inside-cut and foil crimping functions

Synchronised Transfer

With the developments improving the ‘traditional stepper belt’ which is now a high-speed continuous flow the whole process cycle has been slowed down without reducing output. The new synchronised transfer movement is linked to the pickup point and is dramatically reduced in transfer speed. This gives a fully controlled pack transfer cycle.

The key benefits of this development are:

- Increased cycle speeds

- Less aggressive transfers

- Reduction in product movement in the tray

- Eliminates misplaced packs

- Increases longevity of the transfer carriage

Packaging Materials:

- Plastic trays

PP, A-PET, C-PET, R-PET,

- Plant based bioplastic trays

Polylactic Acid (PLA)

- Foil trays

Smooth Wall Foil Trays

- Pulp and Board trays

Pressed, Folded or Pulp Trays

- Lidding materials

Reel-fed Plastic Film and Foil

The REV machines are the fastest, most energy efficient and flexible single lane tray sealers incorporating PA’s latest technology and with the REV3 Plus a small and compact footprint. Using proven syncroflex control ensures a continuous flow of trays through the machine from infeed to outfeed, eliminating the need for any pausing or buffering. To add to it’s versatility it can accommodate SL4 tools so that improvements in machine outputs can be achieved. Dependant on tray size it can seal up to 5 packs at a time giving an output of 125 packs per minute. Electric supply only is required for this machine.

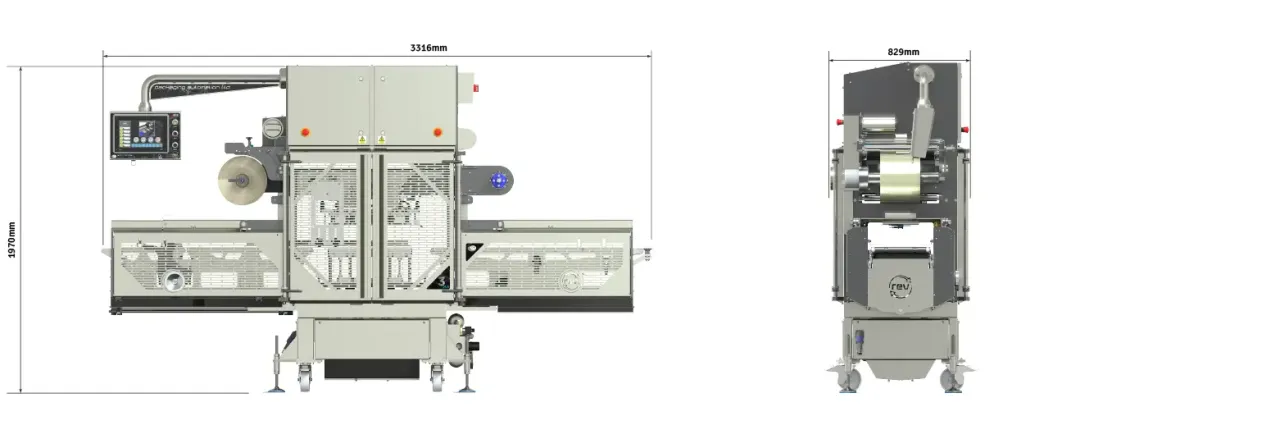

Technical Specifications:

| rev3 plus Specifications | |

| Height | 1970mm |

| Width | 3316mm |

| Depth | 829mm |

| Electrical Supply | 16A 415V 3-Phase N+E 16A Max/Phase, 50/60Hz |

| Pneumatic Supply | N/A |

Features:

Energy Saving

- POWERDRIVE™ – fully electric – zero air

- Automatic standby mode when not in use

- Energy Reload System (ERS)

Efficient

- User-friendly high clarity HMI touch screen

- Interactive HMI with operator prompts

- Accurate monitor temperature control

Intelligent

- Automatic recipe driven film set up

- Auto adjusting film tension system

- Film snap protection

- Easy to follow guided film path for loading

- Intelligent self-diagnosis system

- Tool pack block sensor to avoid smash ups

- Pack crush protection on stepping belt

- Industrial remote access diagnosis

- Interactive screen: coder can be controlled through the machine HMI

- RFID fob access and full audit trail

- DataConnect – online data capture solution. Machine operating linear speed curves programmable for awkward products

- SQL data logger

Future Proofed

- Atmospheric sealing

- MAP-F (Gas Flushing)

- Fully operational from both sides

- Fully portable with fixed locking feet

- Small footprint design in single lane format

- Date coder integration ready

- Bypass/Passive conveyor available

- Industry 4.0 ready

Hygienic

- Full hygienic, robust construction to food industry standards

- Full open access with interlocked guarding and open construction machine bed for hygiene

- Quick release removal conveyors

Flexible Tooling

- POD-tech, cartridge style tooling – gives a 90% reduction in any unplanned downtime

- Tool-less, fast base tool locking mechanism

- Two-minute tool changeover

- Quick release tools

- Inbuilt tool docking system aligns electrical and gas/vacuum connectors

- Lightweight tooling

- Easy height-adjusting telescopic transfer arm

- Quick release cutting blades

- Waterproof heater mats, rapid warm up times

- Eco-cut film saving tooling options

- Inside-cut and foil crimping functions

Synchronised Transfer

With the developments improving the ‘traditional stepper belt’ which is now a high-speed continuous flow the whole process cycle has been slowed down without reducing output. The new synchronised transfer movement is linked to the pickup point and is dramatically reduced in transfer speed. This gives a fully controlled pack transfer cycle.

The key benefits of this development are:

- Increased cycle speeds

- Less aggressive transfers

- Reduction in product movement in the tray

- Eliminates misplaced packs

- Increases longevity of the transfer carriage

Packaging Materials:

- Plastic trays

PP, A-PET, C-PET, R-PET,

- Plant based bioplastic trays

Polylactic Acid (PLA)

- Foil trays

Smooth Wall Foil Trays

- Pulp and Board trays

Pressed, Folded or Pulp Trays

- Lidding materials

Reel-fed Plastic Film and Foil

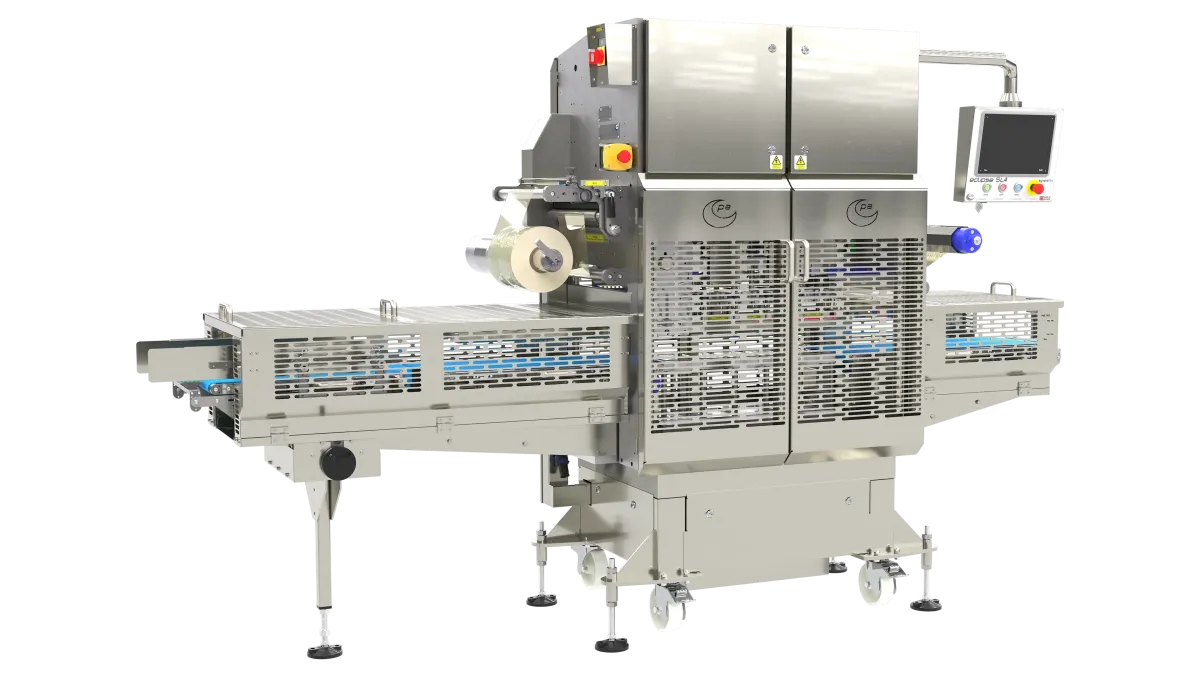

The Eclipse SL4 is a fully electric automatic tray sealer combining medium speed output with quick tool changes and a compact space saving design. Incorporating POWERDRIVE™ technology, there is no requirement for a compressed air supply. It can be used to seal reel fed film to pre-formed trays and can be configured to use MAP-F gas flushing, full MAP-V vacuum and SkinPAC for extended shelf life.

Dependant on the tray size it can seal up to 5 packs at a time giving a maximum output of 75 packs per minute. Electric supply only is required for this machine.

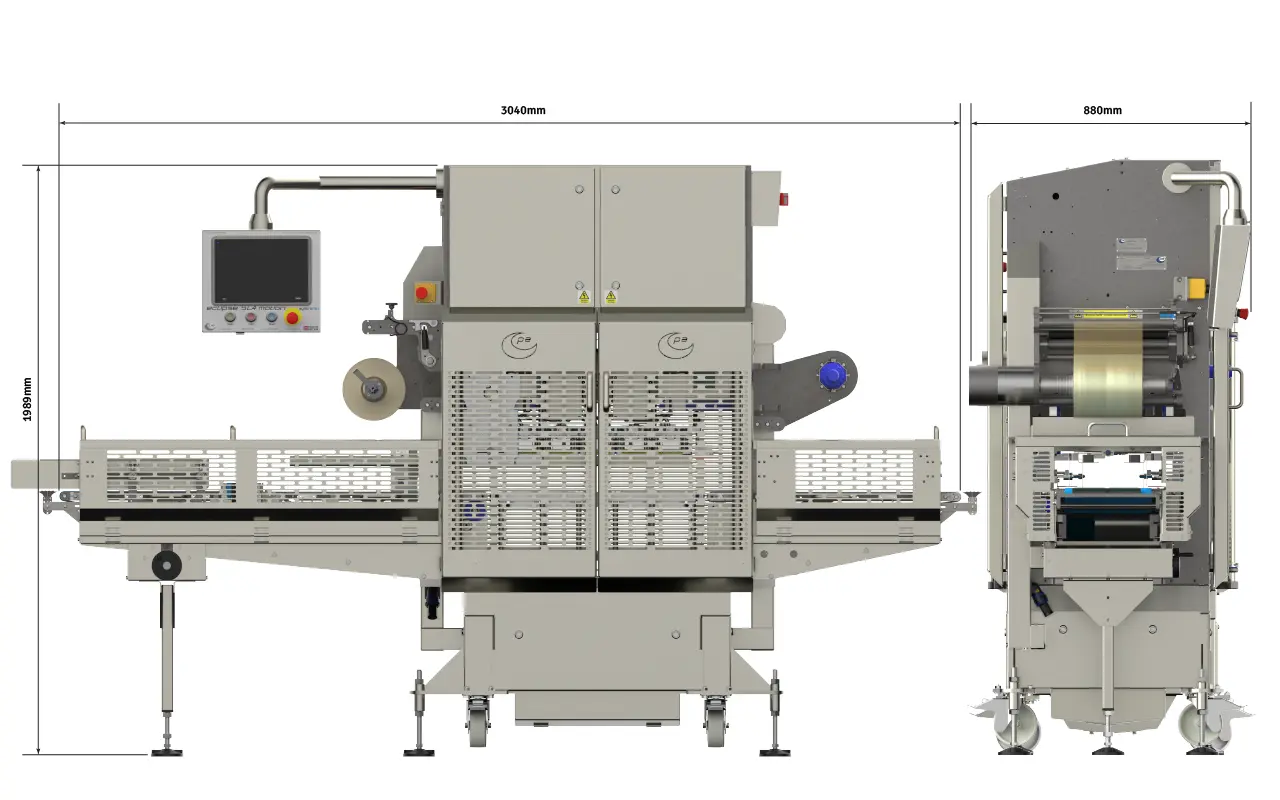

Technical Specifications:

| eclipse SL4 Specifications | |

| Height | 1989mm |

| Width | 3040mm |

| Depth | 880mm |

| Electrical Supply | 16A 415V 3 Phase N+E 15A max/phase 50/60Hz |

| Pneumatic Supply | Not required |

Features:

Energy Saving

- POWERDRIVE – fully electric – zero air

- ‘Soft Seal’ profile function – quiet mode

- Automatic standby mode when not in use

- Reduced gas consumption with MAP sealing

Efficient

- User-friendly high clarity 12″ HMI touch screen

- Interactive HMI with operator prompts

- Manually adjustable self-centring in-feed guides (servo option available)

- Accurate monitor temperature control

- Zonal guarding protection system

Intelligent

- Automatic recipe driven film set up

- Auto adjusting film tension system

- Film snap protection

- Easy to follow guided film path for loading

- Intelligent self-diagnostic system

- Tool pack block sensor to avoid smash ups

- Dual pack crush protection on stepping belt and in sealing zone

- Industrial remote access diagnosis

- Interactive screen – coder can be controlled through the machine HMI

- RFID fob access and full audit trail

- DataConnect – online data capture solution

- SQL data logger

Future Proofed

- Atmospheric sealing

- MAP-F (Gas Flushing)

- MAP-V (Vacuum/Gas Flushing)

- SkinPac – below the sealing edge

- SkinPac Plus – up to 100mm above the base of tray

- Fully operational from both sides

- Fully portable with fixed locking feet

- Date coder integration ready

- Bypass/Passive conveyor available

- Industry 4.0 ready

Hygienic

- Full hygienic, robust construction to food industry standards

- Full open access with interlocked guarding and open construction machine bed for hygiene

- Quick release removable conveyors

Flexible Tooling

- POD-tech, cartridge style tooling – gives a 90% reduction in any unplanned downtime

- Two-minute tool changeover

- Quick release tools

- Inbuilt tool docking system aligns electrical and gas/vacuum connectors

- Lightweight tooling

- Easy height-adjusting transfer arm

- Quick release cutting blades

- Waterproof heater mats, rapid warm up times

- Eco-cut film saving tooling options

- Inside-cut and foil crimping functions

Packaging Materials:

- Plastic trays

PP, A-PET, C-PET, R-PET,

- Plant based bioplastic trays

Polylactic Acid (PLA)

- Foil trays

Smooth Wall Foil Trays

- Pulp and Board trays

Pressed, Folded or Pulp Trays

- Lidding materials

Reel-fed Plastic Film and Foil