Flow Wrapper – Rotary End Sealing

Horizontal Form Fill and Seal Flow Wrapper

Flow wrapping machine that makes a three sealing pillow pack, with rotary motion end sealing for high-speed running, can be equipped with different level control system to suit various packaging requirement.

Flow pack machine for cards, candy, biscuits, masks, etc.

Entry level horizontal flow wrapper (HFFS), a compact machine which is ideal for small-scale production, achieves productivity goals and meets budget requirements.

Features:

- All in one machine frame with powder coating.

- One set of auto centering reel holder.

- Two sets of center sealers, one cold & one heated.

- PLC program control.

- Dancing roller for better film tension control.

- Yaskawa inverter speed variation.

- Electronic bag length adjust device.

- Panasonic photocell for print mark registration.

- Bag length / bag counting display.

- 4 sets OMRON P.I.D. temperature controller.

- 2.3 M long in-feed conveyor & adjustable in-feed guide.

Specifications:

| Model No. | CWM-35 | CWM-47 | CWM-61 |

| Capacity (PPM) | 20 ~ 230 | 20 ~ 180 | 10 ~ 120 |

| Bag Length (mm) | 60 ~ 350 | 100 ~ 450 | 150 ~ 500 |

| Max. Film Width (mm) | 350 | 470 | 610 |

| Max. Product Width (mm) | 145 | 190 | 270 |

| Max. Product Height (mm) | 70 | 100 | 100 |

| Electricity | 3.7 Kw – AC-220 Volt – Single phase | ||

The Max. product height is according to the applications & products range.

Higher product is available as requested.

Packaging Applications:

- Bakery

- Biscuits & Snacks

- Candy & Confectionery

- Refrigerated & Frozen Food

- Fresh

- Shrink Packaging

- Wet Wipes / Tissue

- Printing Items

- Detergents

- Pharmaceutical & Medical

- Hardware & Tool

- Instant Noodles

- Miscellaneous

Flow pack machine for cards, biscuits, masks, etc.

Entry level flow wrapper with servo driven system which is ideal for new users who are getting started in flow wrap packaging, achieves productivity goals and meets budget requirements.

Features:

- Powder coating machine frame.

- 1 axis servo motor system makes the machine running precisely and smoothly.

- 1 set of rotary end sealing jaw.

- Siemens PLC program control.

- 1 set of auto centering reel holder.

- With precise OMRON P.I.D. temperature controller.

- 5.7″ colorful touch panel with 50 sets products data memories.

- Mark registration with Panasonic sensor as standard function.

- Dancing roller and motorized film feeding rollers keep the film tension stable.

- 2.3 M long in-feed conveyor and adjustable guides.

Specifications:

| Model No. | CWS-35 | CWS-47 | CWS-61 |

| Capacity (PPM) | 20 ~ 230 | 30 ~ 230 | 20 ~ 180 |

| Bag Length (mm) | 60 ~ 350 | 70 ~ 350 | 130 ~ 450 |

| Max. Film Width (mm) | 350 | 470 | 610 |

| Max. Product Width (mm) | 145 | 190 | 265 |

| Max. Product Height (mm) | 30 / 60 / 90 mm with jaws Dia. in 88 / 120/ 160 mm | ||

| Electricity | 4.1Kw – AC-220 Volt – 3 phase + Ground | ||

The Max. product height is according to the applications & products range.

Higher product is available as requested.

Packaging Applications:

- Bakery

- Biscuits & Snacks

- Candy & Confectionery

- Refrigerated & Frozen Food

- Fresh

- Shrink Packaging

- Wet Wipes / Tissue

- Printing Items

- Detergents

- Pharmaceutical & Medical

- Hardware & Tool

- Instant Noodles

- Miscellaneous

Flow pack machine for dates, maamouls, cards, etc.

A basic horizontal flow wrapper (HFFS), which can pack a variety of solid items, achieves productivity goals and meets budget requirements.

Features:

- Powder coating machine frame.

- One set of rotary end sealing jaw.

- One set of auto centering reel holder.

- Two sets of center sealers, one cold & one heated.

- PLC program control.

- Dancing roller for better tension control.

- Japanese Yaskawa inverter speed variation.

- Electronic bag length adjust device.

- Japanese Panasonic photocell for print mark registration.

- Bag length / bag counting display.

- Running speed display.

- 4 sets Japanese OMRON P.I.D. temperature controller.

- Fixed modular bag forming box.

- 2.3 M long in-feed conveyor & adjustable in-feed guide.

Specifications:

| Model No. | JE-535 | JE-547 | JE-561 |

| Capacity (PPM) | 20 ~ 230 | 20 ~ 180 | 10 ~ 100 |

| Bag Length (mm) | 60 ~ 350 | 100 ~ 450 | 150 ~ 500 |

| Max. Film Width (mm) | 350 | 470 | 610 |

| Max. Product Width (mm) | 145 | 190 | 270 |

| Max. Product Height (mm) | 70 | 100 | 100 |

| Electricity | AC220V – Single phase | ||

The Max. product height is according to the applications & products range.

Higher product is available as requested.

Packaging Applications:

- Bakery

- Biscuits & Snacks

- Candy & Confectionery

- Refrigerated & Frozen Food

- Fresh

- Shrink Packaging

- Wet Wipes / Tissue

- Printing Items

- Detergents

- Pharmaceutical & Medical

- Hardware & Tool

- Instant Noodles

- Miscellaneous

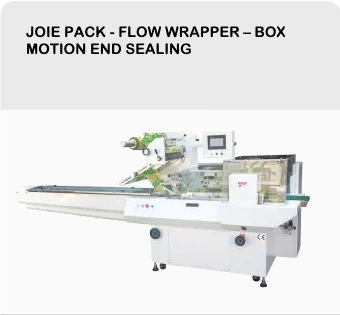

Flow pack machine for cakes, masks, biscuits with tray, etc.

A basic level horizontal flow pack machine (HFFS), which can pack a variety of industrial products, achieves productivity goals and meets budget requirements.

An ideal solution for both food and non-food packaging.

Features:

- Powder coating machine frame.

- PLC program control.

- 4 independent OMRON P.I.D. temperature controller.

- Print mark registration with Japanese Panasonic photocell as a standard function.

- Overload protection for end sealer with auto disengage function.

- Protection device for in-feed pusher makes the in-feed reset easily.

- Top brush belt makes the product transfer smoothly at high running speed.

- Dancing roller and motorized film feeding rollers keep the film tension stable.

- Home reset button makes the film change-over quick and easy.

- Special bag length auto tuning function makes the print mark registration reliable.

Specifications:

| Model No. | M-5235 | M-5247 | M-5261 |

| Capacity (PPM) | 30 ~ 270 | 30 ~ 230 | 20 ~ 180 |

| Bag Length (mm) | 70 ~ 350 | 70 ~ 350 | 130 ~ 450 |

| Max. Film Width (mm) | 350 | 470 | 610 |

| Max. Product Width (mm) | 145 | 190 | 265 |

| Max. Product Height (mm) | 30 / 60 / 90 mm with jaws Dia. in 88 / 120 / 160 mm | ||

| Electricity | 3.7 Kw – AC-220 Volt – 1 phase + Ground | ||

The Max. product height is according to the applications & products range.

Higher product is available as requested.

Packaging Applications:

- Bakery

- Biscuits & Snacks

- Candy & Confectionery

- Refrigerated & Frozen Food

- Fresh

- Shrink Packaging

- Wet Wipes / Tissue

- Printing Items

- Detergents

- Pharmaceutical & Medical

- Hardware & Tool

- Instant Noodles

- Miscellaneous

Flow pack machine for masks, cookies, cards, soaps, etc.

Servo flow wrapper which can pack both food and non-food products, achieves productivity goals and satisfies budget requirements.

Features:

- 1 axis servo motor drive.

- One set of rotary end sealing jaw.

- One set of auto centering reel holder.

- Two sets of center sealing wheel, one cold & one heated.

- Siemens PLC program control.

- Shinko P.I.D. temperature control modular.

- Japanese Yaskawa inverter speed variation.

- Japanese Panasonic photocell for film registration.

- 7″ touch panel with 50 sets of products data memories.

- Adjustable bag former or modular bag forming box.

- 2.3 M long in-feed conveyor & adjustable in-feed guide.

- Safety protection guards for end sealing station.

- End sealer overload protection device with auto disengage function.

- European CE safety standard.

Specifications:

| Model No. | S-5535 | S-5547 | S-5561 |

| Capacity (PPM) | 30 ~ 270 | 30 ~ 230 | 20 ~ 180 |

| Bag Length (mm) | 70 ~ 350 | 70 ~ 350 | 130 ~ 500 |

| Max. Film Width (mm) | 350 | 470 | 610 |

| Max. Product Width (mm) | 145 | 190 | 265 |

| Max. Product Height (mm) | 30 / 60 / 90 mm with jaws Dia. in 88 / 120 / 160 mm | ||

| Electricity | 4.1 Kw – AC-220 Volt – 3 phase + Ground | ||

The Max. product height is according to the applications & products range.

Higher product is available as requested

Packaging Applications:

- Bakery

- Biscuits & Snacks

- Candy & Confectionery

- Refrigerated & Frozen Food

- Fresh

- Shrink Packaging

- Wet Wipes / Tissue

- Printing Items

- Detergents

- Pharmaceutical & Medical

- Hardware & Tool

- Instant Noodles

- Miscellaneous

Flow pack machine for bakery, masks, tools, etc.

The servo driven flow wrapper can pack a wide range of regularly shaped, solid items from both food and non-food industries. A range of automation solutions for continuous feeding is also available.

With 100 sets of parameter memories, the flow wrapper is easy to operate with low maintenance costs.

Features:

- 3 axis servo motor drive units for in-feed, center sealing, and end sealing.

- Japanese Yaskawa Motion Controller

- Shinko P.I.D. temperature control modular.

- 1 set of rotary end sealing jaw.

- 1 set of auto centering reel holder.

- 10.4″ colorful touch screen with 100 sets of products data memories.

- Print mark registration with Japanese Panasonic sensor as standard function.

- Home button makes the packaging data change-over easy.

- Overload protection for end sealer with auto disengage function.

- Top brush belt makes the items transfer smoothly at high running speed.

- Dancing roller and motorized film feeding rollers keep the film tension stable.

Specifications:

| Model No. | S-5635 | S-5647 | S-5661 |

| Capacity (PPM) | 30 ~ 270 | 30 ~ 230 | 20 ~ 180 |

| Bag Length (mm) | 70 ~ 350 | 70 ~ 350 | 130 ~ 500 |

| Max. Film Width (mm) | 350 | 470 | 610 |

| Max. Product Width (mm) | 145 | 190 | 265 |

| Max. Product Height (mm) | 30 / 60 / 90 mm with jaws Dia. in 88 / 120 / 160 mm | ||

| Electricity | 5.5 Kw – AC-220 Volt – 3 phase + Ground | ||

The Max. product height is according to the applications & products range.

Higher product is available as requested.

Packaging Applications:

- Bakery

- Biscuits & Snacks

- Candy & Confectionery

- Refrigerated & Frozen Food

- Fresh

- Shrink Packaging

- Wet Wipes / Tissue

- Printing Items

- Detergents

- Pharmaceutical & Medical

- Hardware & Tool

- Instant Noodles

- Miscellaneous