Customised and scalable turnkey freeze-drying solutions for the pharmaceutical and biotech industries

Optima Pharma’s modular systems for lyophilization (pharmaceutical freeze-drying) are precisely tailored to any production processes. Whatever the scale of application, from clinical trials to commercial production, Optima’s freeze-dryers provide an adaptable turnkey solution for pharmaceutical lyophilization.

Optima’s integrated approach makes the go-to partner for lyophilizers, filling lines and isolators. Optima make seamlessly integrating lyophilization equipment into pharmaceutical infrastructure a breeze. On top of this, the comprehensive turnkey project management takes the complexity out of any project. From consulting to standardized interfaces and documentation of the entire system, personal Optima Pharma expert will always be supportive.

Optima’s expertise in pharmaceutical freeze-drying gives customized, efficient solutions and innovative, scalable lyophilization equipment for production. Whether. installing a new system or upgrading an existing one, Optima Pharma’s lyophilizers meet the highest pharmaceutical standards, reducing time to market and safeguarding product stability.

An overview of Optima’s lyophilization machines

Explore the versatile range of lyophilization and pharmaceutical freeze-drying machines tailored for every application, from new setups to system updates or renovations.

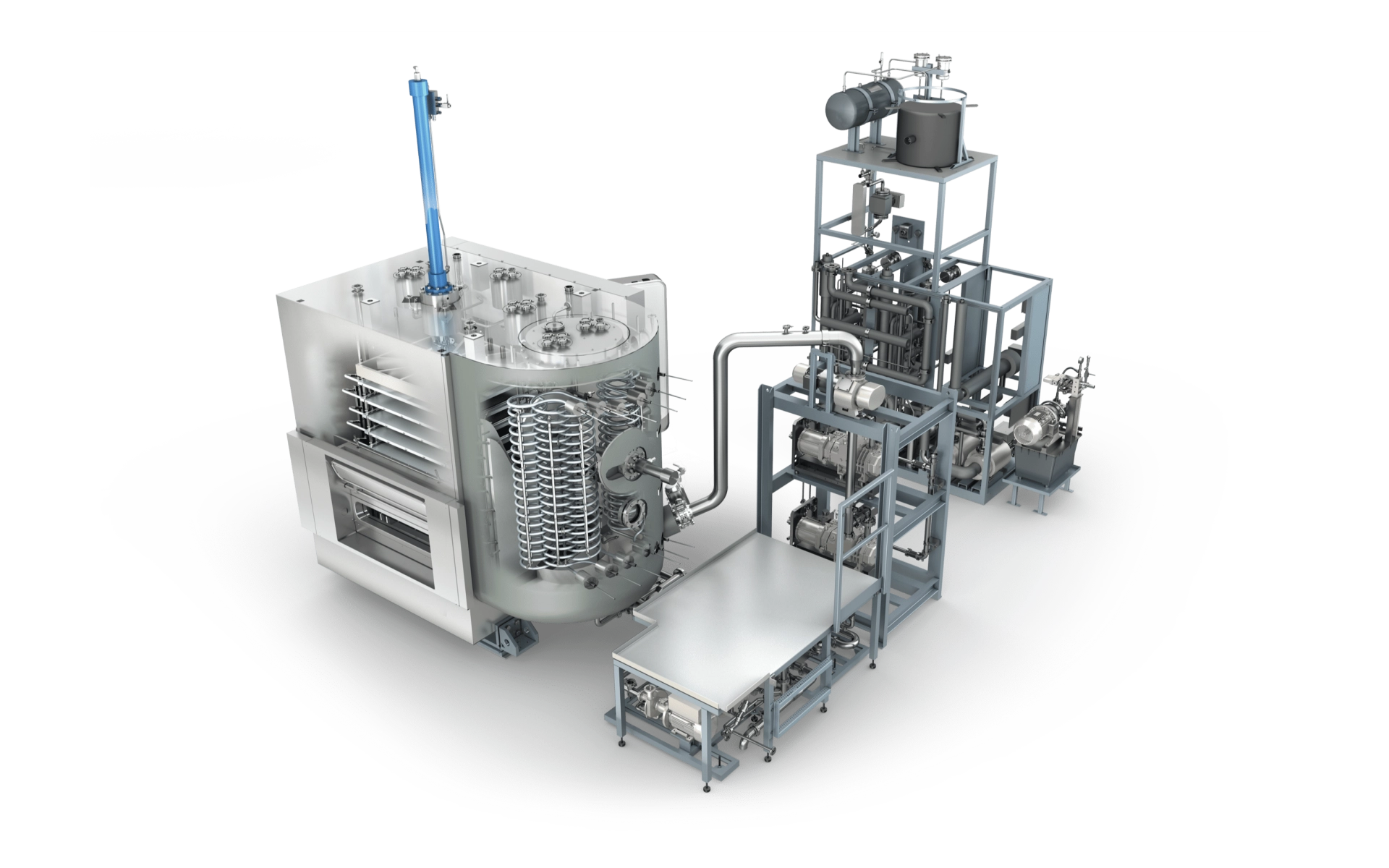

Compact and flexible

The OPTIMA LYO-C lyophilizer is designed to be compact and flexible, allowing it to be easily fitted into various pharmaceutical setups. Space is used efficiently without any compromise on performance.

Plate surface: 1–10 m²

Ice capacity: 10–200 kg

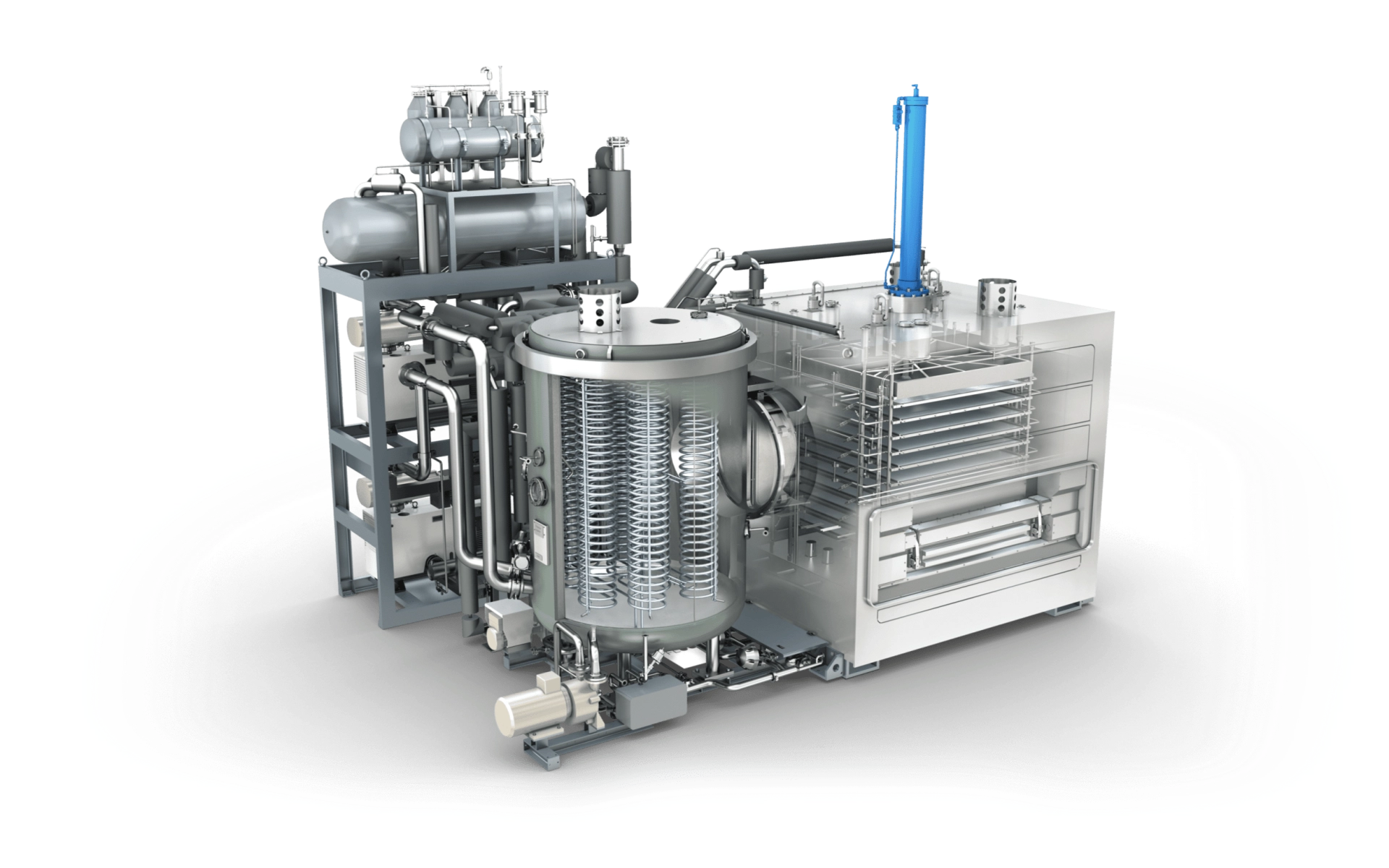

Efficiency in small-batch lyophilization

Designed for small to medium batch sizes, the OPTIMA LYO-CS is a flexible and cost-effective lyophilizer that is perfect for processing pharmaceutical products in the development stages.

Plate surface: 5–20 m²

Ice capacity: 100–600 kg

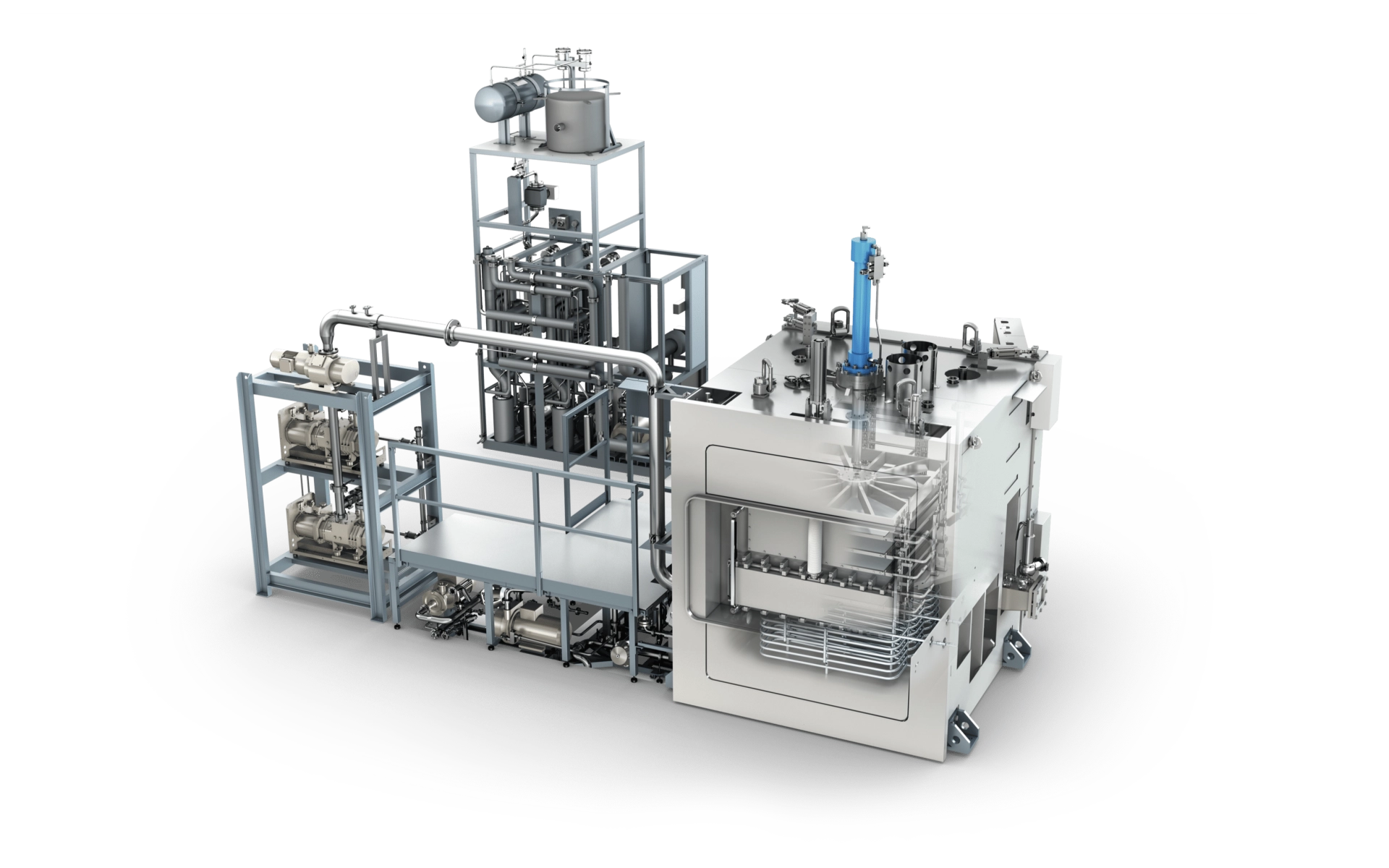

High-performance pharmaceutical freeze-drying

The OPTIMA LYO-S is our high-capacity lyophilizer. This pharmaceutical freeze-dryer excels in handling large volumes, ensuring safe and reliable lyophilization for pharmaceutical blockbusters. The chamber is designed as a stand-alone unit, with the intermediate valve as a separate component. The LYO-S can be loaded manually or automatically.

Plate surface: 5–40 m²

Ice capacity: 100–800 kg

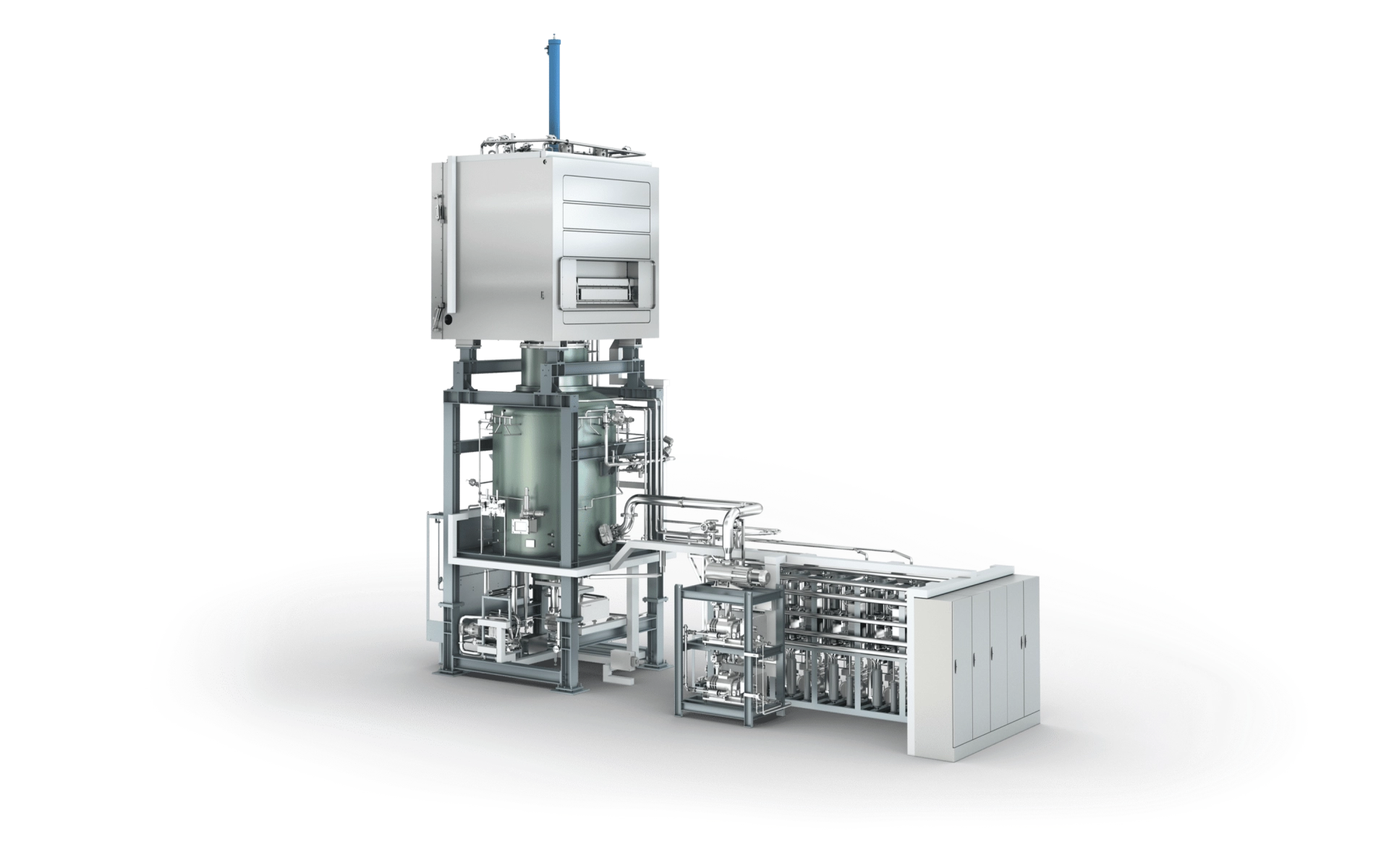

High performance in a small package

Effective lyophilization but space is at a premium, the OPTIMA LYO-D is the solution. Its innovative two-level design separates the clean room and machine functions, and makes it easy to integrate into existing pharmaceutical production environments. In addition, a service door that can be fitted on the side makes life easier for operating personnel.

Plate surface: 5–40 m²

Ice capacity: 100–800 kg

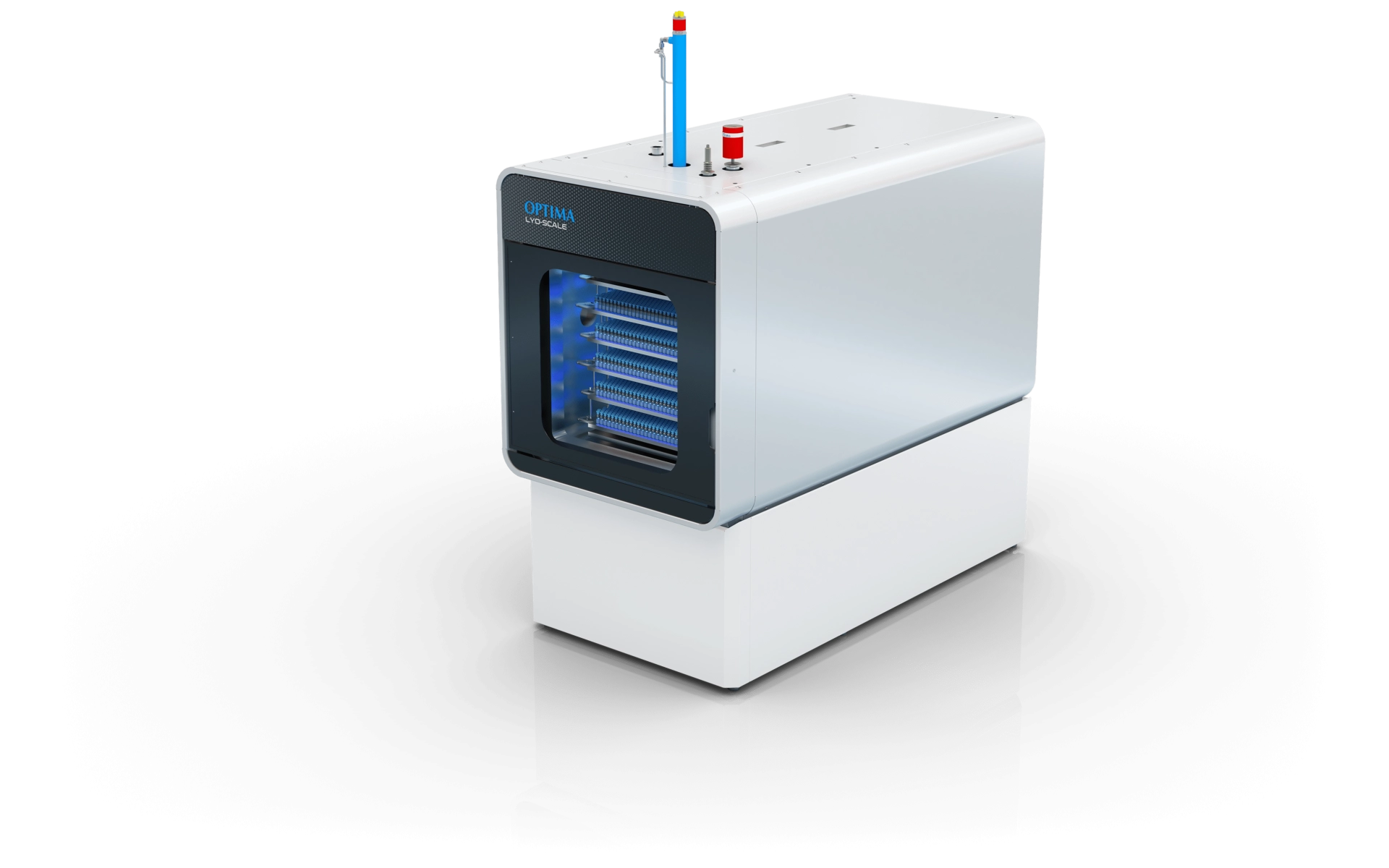

From small scale to commercial production

With the OPTIMA LYO-SCALE, recipe parameters for lyophilization processes can be developed on a small scale and precisely scaled-up for larger systems. Optima’s lyophilization solutions preserve highly sensitive pharmaceutical or biotech drugs and ensure maximum shelf life. Integrated into a filling line with isolator, they provide customers a complete turnkey system.

- Control and monitoring by process analytical tools (PAT)

Options for redundancy, mass spectromety and cleaning