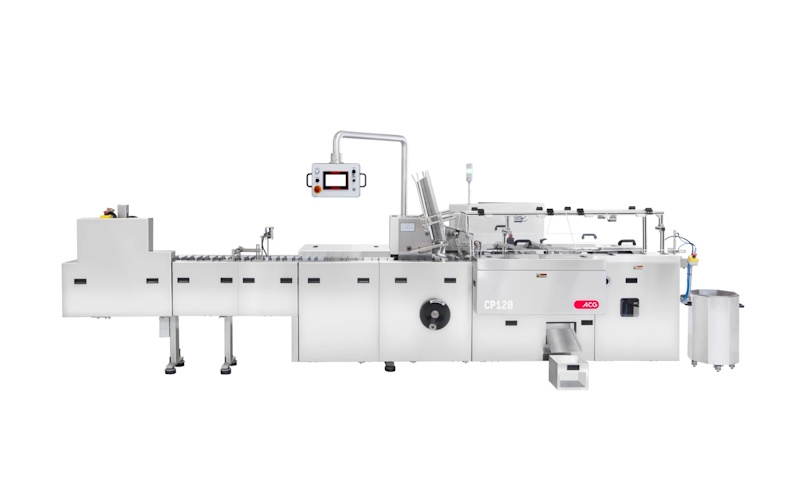

CP 120

About the CP 120

In a market where machine flexibility can trump production, CP 120 is a highly effective continuous-motion, horizontal cartoning machine. With more than 300 successful installations, this robust machine, created for low power consumption, showcases ACG’s design expertise based on proven engineering concepts.

Applications

Blister packs, multipacks, bottles, vials, ampoules, tubes, soaps and other rigid products

Features |

Benefits |

|

|---|---|---|

| Suitable for reverse tuck-in, parallel/aeroplane tuck-in, glue closure, or combinations of tuck-in and glue closure |  |

Cost-effective – highly versatile in handling a wide variety of carton closures |

| Available in tailored configurations |  |

Helps you meet specific customer requirements quickly and easily |

| Built-in ‘No product-No leaflet-No carton’ system |  |

Ensures reliable, error-free output |

| Can be integrated with primary packaging machines |  |

Allows integration with a wide range of primary packaging applications |

| Option to extend product conveyor |  |

Meets different packaging requirements |

Technical specification |

|||

| Maximum output |

120 cartons/min |

||

| 2 Chain | Carton width | Min |

20 mm |

| Max |

100 mm |

||

| Carton height | Min |

15 mm |

|

| Max |

65 mm |

||

| Carton length | Min |

45 mm |

|

| Max |

70 mm |

||

| 3 Chain | Carton width | Min |

20 mm |

| Max |

100 mm |

||

| Carton height | Min |

15 mm |

|

| Max |

65 mm |

||

| Carton length | Min |

65 mm |

|

| Max |

180 mm |

||

| 4 Chain | Carton width | Min |

20 mm |

| Max |

100 mm |

||

| Carton height | Min |

15 mm |

|

| Max |

65 mm |

||

| Carton length | Min |

95 mm |

|

| Max |

205 mm |

||

| Carton type | Reverse tuck-in, glued type, parallel tuck-in, front tuck-in/rear gluing | ||