Continuous Manufacturing

The innovation and cost pressure in the industry is constantly increasing. As a result, more and more OSD dosage forms are being produced in Continuous Manufacturing processes.

Fette Compacting relies on the highly efficient direct compression process for continuous tableting systems. After dosing, the powder is fed directly from the mixer into the tablet press without additional granulation. Compared to other continuous processes, several costly and complex production steps can be omitted. Since the short, three-step production process requires only small equipment, it takes up very little space. Direct compression offers a lot of flexibility and enables quick product changes. It also provides a guarantee of quality: by feeding the powder from the mixer directly into the tablet press in a continuous flow, factors that might reduce quality can be minimized.

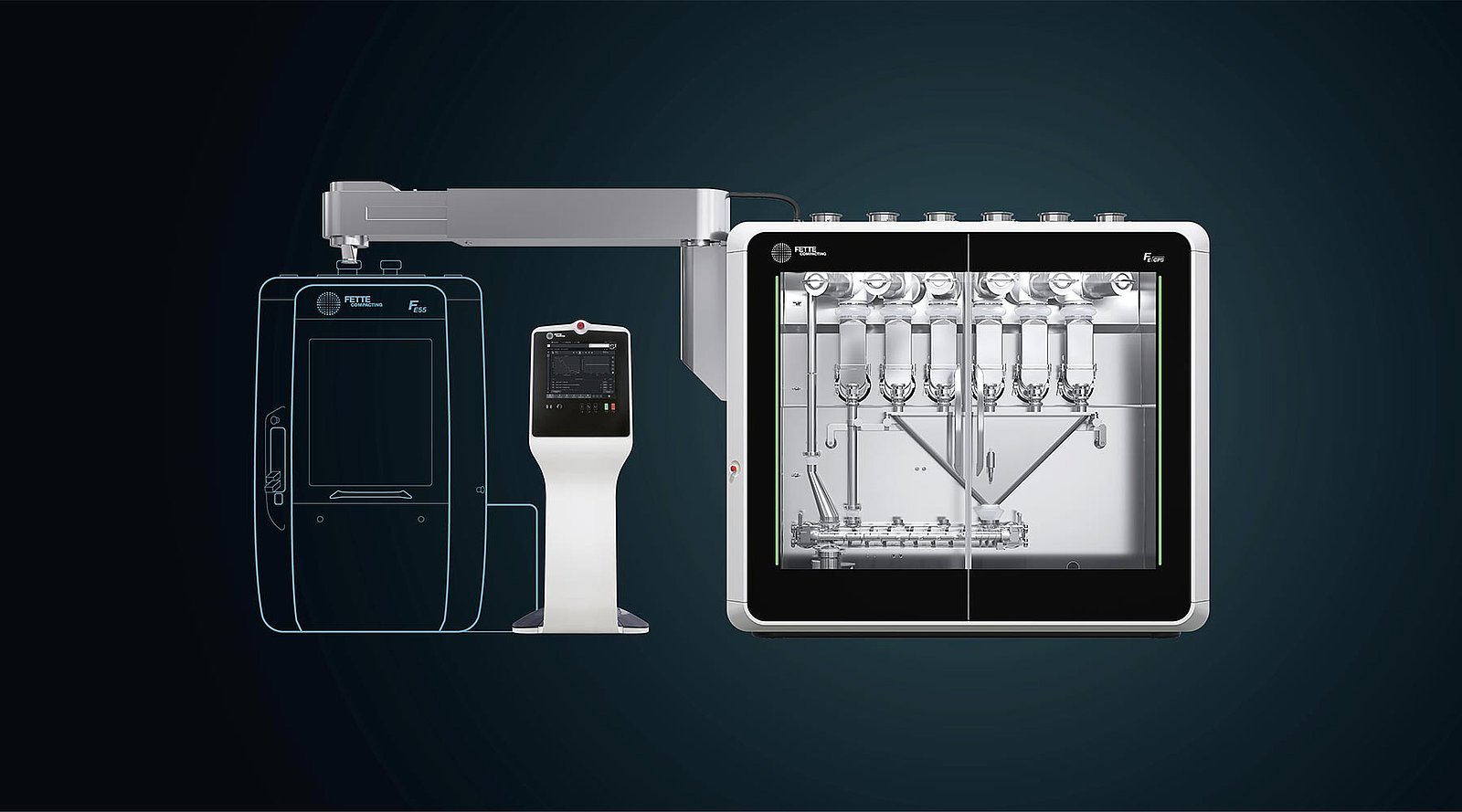

FE CPS – the gamechanger

Lean plant design. Short process time. Fast product changeovers. Continuous manufacturing has never been easier, more cost-efficient and more flexible.

One single central control system for simultaneous machine, process and quality control. To monitor the decisive quality attributes, the system features innovative in-line process analysis technology: embedded Process Analytical Technology or ePAT for short. In this process, sophisticated sensors are integrated into the process units where they monitor the relevant production parameters. This enables swift reactions to fluctuations in quality and direct adjustment of the production process.