Carton Serialisation

VERISHIELD CS series

The CS series consists of a range of accurate and reliable carton serialisation systems. Easy to use, they can serialise cartons of various sizes, from small blister packs to large shipping containers.

The CS series consists of a range of accurate and reliable carton serialisation systems. Easy to use, they can serialise cartons of various sizes, from small blister packs to large shipping containers. They comply with regulatory requirements all over the world and are suitable for providing a high level of security and traceability of pharmaceutical products.

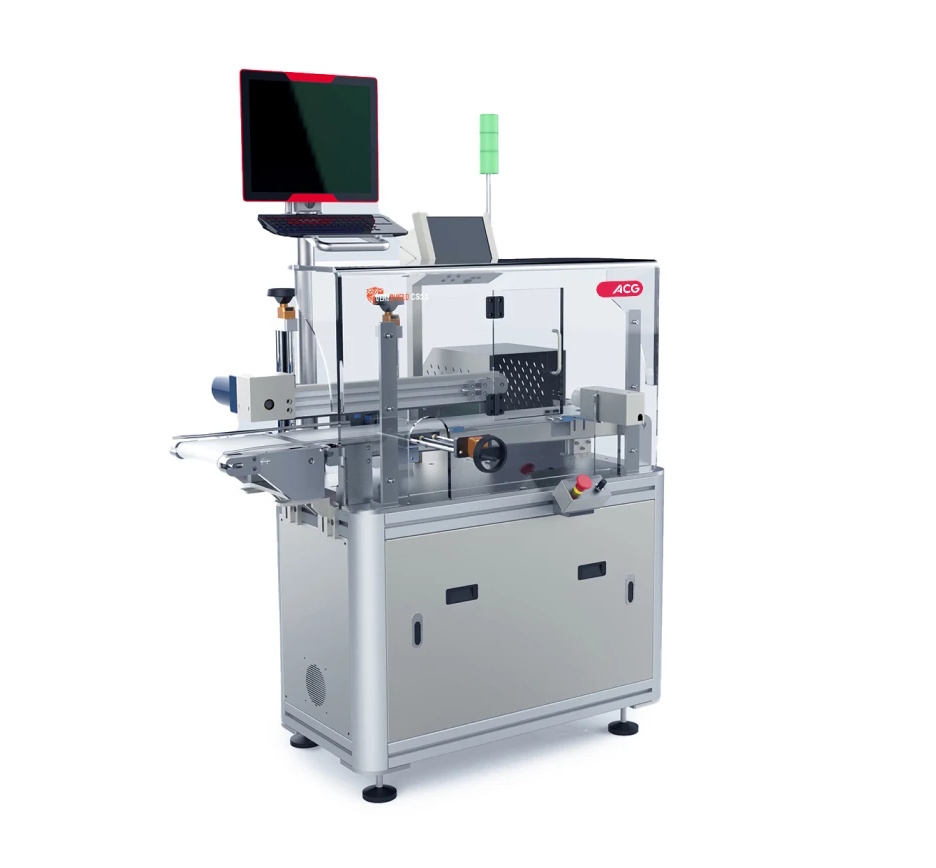

VERISHIELD CS11 is our carton serialisation system for online printing, inspection, and rejection of cartons with defective print.

Functionality

Online print, inspect and reject

| Features | Benefits | |

|---|---|---|

| Adjustable for different carton dimensions |  |

Allows quick changeover between multi-carton sizes |

| Equipped with variable speed control |  |

Flexibility to adjust speed as per online output requirements |

|

Supports track & trace regulations of multiple countries

Capable of printing datamatrix code as per regulations |

|

A single machine that fulfils diverse requirements of different regulations |

| EU Annex 11 and FDA 21 CFR Part 11 compliant with CE certification |  |

A regulatory-compliant, audit-friendly system |

| Plug-and-play mode |  |

The system can connect seamlessly with cartoners/checkweighers |

| Works on serialised and non-serialised modes of operation |  |

Option to print details on carton based on printing format requirements |

Technical specifications

| Machine dimensions | Length | 1,350mm | |

| Width | 1,060 mm | ||

| Height | 1,990±60 mm | ||

| Maximum throughput |

200 cartons/min (for minimum carton size) |

||

| Carton size range | Min | Length | 65 mm |

| Width | 30 mm | ||

| Height | 15 mm | ||

| Max | Length | 200 mm | |

| Width | 200 mm | ||

| Height | 150 mm | ||

| Maximum carton weight | 500 g | ||

| Printing and verification (serialisation) | 2D Datamatrix and up to 5 lines of human readable fields | ||

| Rejection system | Encoder based rejection system with lock and key rejection bin | ||

| Interlock and safety |

Emergency stop |

||

| Report types |

Batch-wise report |

||

The CS series consists of a range of accurate and reliable carton serialisation systems. Easy to use, they can serialise cartons of various sizes, from small blister packs to large shipping containers. They comply with regulatory requirements all over the world and are suitable for providing a high level of security and traceability of pharmaceutical products.

VERISHIELD CS12 allows you to serialise your cartons offline. The machine also prints, inspects, and rejects cartons ensuring only the correctly printed and serialised cartons reach the market.

Functionality

Offline print, inspect and reject

| Features | Benefits | |

|---|---|---|

| Adjustable for different carton dimensions |  |

Allows quick changeover between multi-carton sizes |

| Equipped with variable speed control |  |

Flexibility to adjust speed as per online output requirements |

| Supports track & trace regulations of multiple countries |  |

A single machine that fulfils diverse requirements of different regulations |

| EU Annex 11 and FDA 21 CFR Part 11 compliant with CE certification |  |

A regulatory-compliant, audit-friendly system |

| Works on serialised as well as non-serialised modes of operation |  |

Option to print details on cartons based on printing format requirements |

Technical specifications

| Machine dimensions | Length | 1,750 mm | |

| Width | 1,050 mm | ||

| Height | 1,840±65 mm | ||

| Maximum throughput |

200 cartons/min (for minimum carton size) |

||

| Carton size range | Min | Length | 65 mm |

| Width | 60 mm | ||

| Max | Length | 300 mm | |

| Width | 200 mm | ||

| Rejection system | Encoder based rejection system with lock and key rejection bin | ||

| Interlock and safety |

Emergency stop |

||

| Report types |

Batch-wise report |

||

The CS series consists of a range of accurate and reliable carton serialisation systems. Easy to use, they can serialise cartons of various sizes, from small blister packs to large shipping containers. They comply with regulatory requirements all over the world and are suitable for providing a high level of security and traceability of pharmaceutical products.

VERISHIELD CS14 is a carton serialisation machine equipped with a check-weigher. The machine is adjustable to cartons of different dimensions and can be easily integrated with various carton packaging machines. Further, you can quickly change over between multi-carton sizes and, in the end, get a consolidated production report.

Functionality

Online print, inspect and reject with check-weigher

| Features | Benefits | |

|---|---|---|

| Compactly designed check-weighing solution with an accuracy of +0.5g |  |

Occupies much lesser floor space as compared to a separate check-weigher, print and inspection unit |

| Online serialisation, barcode printing, data printing (GTIN, expiry, batch number and unique serial number as per GS1 guidelines) |  |

Printing and inspection as per specific regulatory requirements |

| Supports both serialised and non-serialised batches |  |

A single machine that meets diverse requirements of different regulations

Provision to print and inspect products for regulated and non-regulated markets |

| EU Annex 11 and FDA 21 CFR Part 11 compliant with CE certification |  |

A regulatory-compliant, audit-friendly system |

Technical specifications

| Machine dimensions | Length | 1,750 mm | |

| Width | 1,060 mm | ||

| Height | 1,950±60 mm | ||

| Maximum throughput |

150 cartons/min (for minimum carton size) |

||

| Carton size range | Min | Length | 80 mm |

| Width | 30 mm | ||

| Height | 15 mm | ||

| Max | Length | 180 mm | |

| Width | 90 mm | ||

| Height | 90 mm | ||

| Carton weight | Min | 10 g | |

| Max | 500 g | ||

| Field of view | 50 mm x 25 mm | ||

| Interlock and safety |

Emergency stop |

||

| Report types |

Batch-wise report |

||

The CS series consists of a range of accurate and reliable carton serialisation systems. Easy to use, they can serialise cartons of various sizes, from small blister packs to large shipping containers. They comply with regulatory requirements all over the world and are suitable for providing a high level of security and traceability of pharmaceutical products.

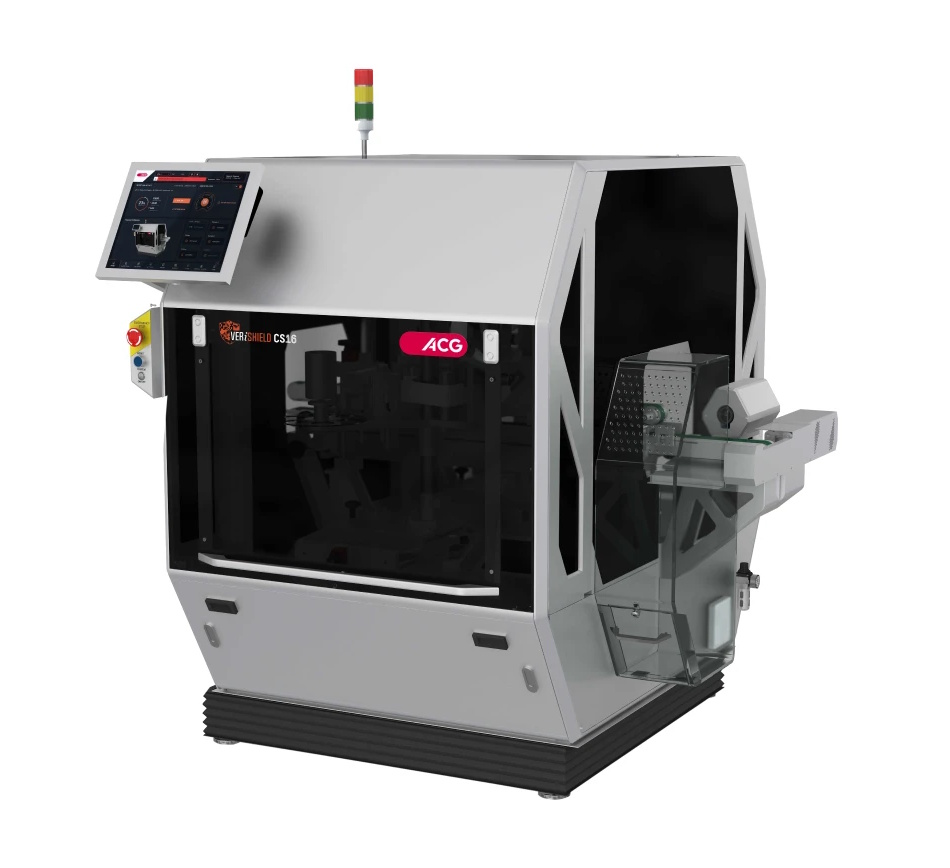

VERISHIELD CS16 is different from our other carton serialisation systems in that it also performs tamper-evident labelling. In addition, it also prints and inspects cartons, and rejects those that are serialised incorrectly or do not have tamper-evident labels. Its plug-and-play mode allows it to work with any cartoning line.

Functionality

Online print, inspect and reject with tamper-evident labelling

| Features | Benefits | |

|---|---|---|

| High-speed machine with a compact design |  |

Minimal space required for integrating in line |

| Online rejection based on serialisation and inspection of tamper evident label (through sensor-based input) |  |

Printing, inspection, label application verification and rejection using a single machine |

| EU FMD regulation compliant |  |

Ideal for products manufactured in or exported to Europe |

| EU Annex 11 and FDA 21 CFR Part 11 compliant with CE certification |  |

A regulatory-compliant, audit-friendly system |

Technical specifications

| Machine dimensions | Length | 1,400 mm | |

| Width | 1,660 mm | ||

| Height | 1,800±65 mm | ||

| Maximum throughput |

300 cartons/min (for minimum carton size) |

||

| Carton size range | Min | Length | 65 mm |

| Width | 30 mm | ||

| Height | 15 mm | ||

| Max | Length | 200 mm | |

| Width | 150 mm | ||

| Height | 90 mm | ||

| Interlock and safety |

Emergency stop button |

||

| Report types |

Batch-wise report |

||

The CS series consists of a range of accurate and reliable carton serialisation systems. Easy to use, they can serialise cartons of various sizes, from small blister packs to large shipping containers. They comply with regulatory requirements all over the world and are suitable for providing a high level of security and traceability of pharmaceutical products.

VERISHIELD CS17 is a carton printing, inspection, and rejection system with tamper evident labelling capability that complies with global regulations. The system is equipped with serialisation printing, advanced vision inspection technology and tamper evident label application capabilities with an operator-friendly interface.

Functionality

Online print inspect and reject with tamper-evident labelling

| Features | Benefits | |

|---|---|---|

| High-speed machine with a compact design |  |

Requires minimal floor space and time |

| Ergonomic, aesthetic design with operator-friendly interface |  |

Easy to operate and maintain the system |

| EU FMD regulation compliant |  |

Ideal for products manufactured in or exported to European countries |

| EU Annex 11 and FDA 21 CFR Part 11 compliant with CE certification |  |

A regulatory-compliant, audit-friendly system |

Technical specifications

| Machine dimensions | Length | 1,400 mm | |

| Width | 1,660 mm | ||

| Height | 1,800±65 mm | ||

| Maximum throughput |

200 cartons/min (for minimum carton size) |

||

| Carton size range | Min | Length | 65 mm |

| Width | 30mm | ||

| Height | 15 mm | ||

| Max | Length | 200 mm | |

| Width | 150mm | ||

| Height | 90 mm | ||

| Rejection system |

Combined rejection bin with rejection verification functionality |

||

| Interlock and safety |

Emergency stop button |

||

The CS series consists of a range of accurate and reliable carton serialisation systems. Easy to use, they can serialise cartons of various sizes, from small blister packs to large shipping containers. They comply with regulatory requirements all over the world and are suitable for providing a high level of security and traceability of pharmaceutical products.

VERISHIELD CS19 carton printing, inspection and rejection system for complying with global regulations. The system is equipped with serialisation printing equipment, advanced vision inspection technology and tamper evident label application capabilities with an operator-friendly interface.

Functionality

Online print and inspection

| Features | Benefits | |

|---|---|---|

| High-speed machine with a compact design |  |

Requires minimal floor space and time |

| Ergonomic, aesthetic design with operator-friendly interface evident label (through sensor-based input) |  |

Easy to operate and maintain the system |

| EU FMD regulation compliant |  |

Ideal for products manufactured in or exported to European countries |

| EU Annex 11 and FDA 21 CFR Part 11 compliant with CE certification |  |

A regulatory-compliant, audit-friendly system |

Technical specifications

| Machine dimensions | Length | 1,564 mm | |

| Width | 890 mm | ||

| Height | 2,026 mm | ||

| Maximum throughput |

400 cartons/min |

||

| Carton size range | Min | Length | 65 mm |

| Width | 30 mm | ||

| Height | 15 mm | ||

| Max | Length | 200 mm | |

| Width | 200 mm | ||

| Height | 150 mm | ||

| Carton weight | 50g to 1kg | ||

| Rejection system |

Time/encoder-based rejection system with pneumatic cylinder and rejection bin |

||

| Interlock and safety |

Machine ready interlock |

||