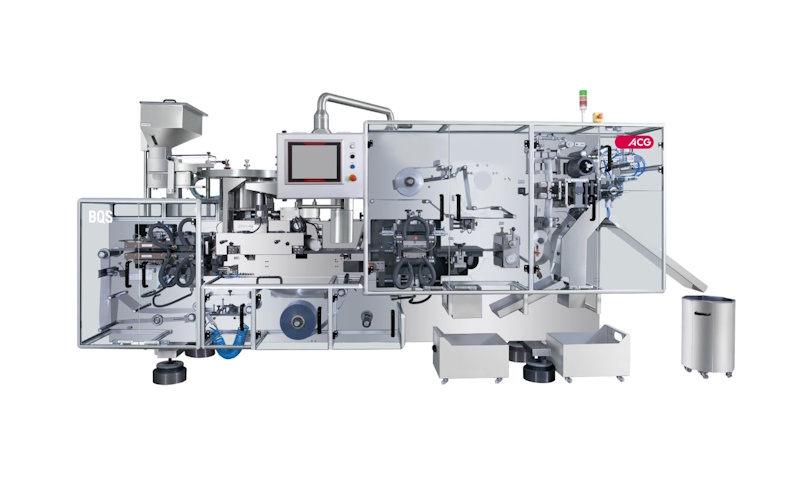

BQS

About the BQS

BQS remains the preference for customers with over 1,000 active blister packaging installations globally. It is a flat-sealing, continuous-motion machine fully capable with the full range of thermoform films and cold-form packaging foils. Powered by servo technology, BQS ensures accuracy, reliability and control, and hence improves productivity.

It’s also highly flexible, and therefore ideal for customising to specific requirements. It comes with full CE/EAC/UL certification, and is equipped with with proprietary ACG SMART CONNECTED technology, enabling remote asset visibility and real-time monitoring of machine health and performance.

Applications

Blister packaging of solid dosage products such as tablets, hard capsules and soft gelatin capsules.

Features |

Benefits |

|

|---|---|---|

| Ergonomic balcony design |  |

Easy access and cleaning, for hassle-free changeover |

| Handles a wide range of thermoform films and cold-form packaging foils |  |

Higher flexibility |

| Optimal format area |  |

Suitable for a variety of blister pack sizes |

| Edge-to-edge blister-pack punching |  |

Improves packaging yield |

| Effortless downstream integration with cartoning machines |  |

Opens up options for blister-cartoning lines |

| Rotary indexing suitable for large blister sizes |  |

Blister width up to 127 mm |

Technical specification |

|||

| Forming cycle | Thermoforming | Up to 45 cycles/min | |

| Cold-forming | Up to 35 cycles/min | ||

| Forming depth | Thermoforming | Up to 12 mm | |

| Cold-forming | Up to 9 mm | ||

| Maximum forming area | 240 mm x 180 mm | ||

| Forming materials | PVC, PVC/PVdC, Aclar, Triplex (PVC/PE/PVdC), cold-form foil (Alu) | ||

| Lidding materials | Push-through foil, child-resistant foil, peelable foil | ||