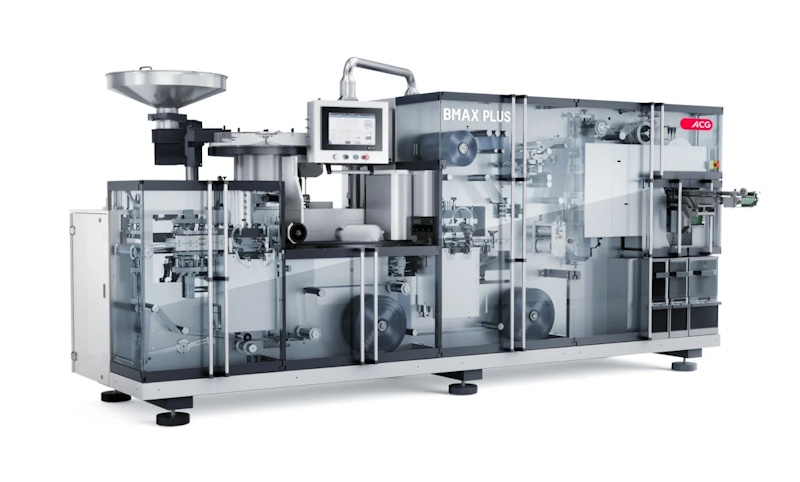

BMAX PLUS

About the BMAX PLUS

Drawing on our vast experience in packaging high-quality blister packs, in more than 6,000 thermoform and cold-form formats, we’ve designed BMAX PLUS to help you meet evolving demands as efficiently as possible. Powered by the latest servo technology, it improves accuracy, speed, reliability and control significantly – making it our most versatile and efficient packaging machine yet. It can handle thermoforming and cold-forming packaging films and foils, and is fully compliant with 21 CFR Part 11.

Applications

Blister packaging of solid dosage products such as tablets, hard capsules and soft gelatin capsules

Features |

Benefits |

|

|---|---|---|

| Servo-enabled, continuous-motion flat-forming and flat-sealing |  |

Higher quality thermoform and cold-form blisters |

| Elegant balcony design with upgraded setting mechanisms |  |

Simpler operation, and changeover Easier cleaning |

| Robust mono-block design |  |

Enables smoother, more reassuring operation |

| Centralised Automated Lubrication System (CALS) |  |

Assured safety, timely lubrication, essential for protection and longevity of critical moving parts |

| Automated pressure settings |  |

Prevention of unauthorised changes and reduced manual intervention ensures output quality and operator safety |

| Edge-to-edge blister-pack punching |  |

Improved packaging yield |

| Rotary ‘pick up’ system |  |

Higher output |

Technical specification |

|||

| Forming cycle | Thermoforming | Up to 50 cycles/min | |

| Cold-forming | Up to 45 cycles/min | ||

| Forming depth | Thermoforming | Up to 12 mm | |

| Cold-forming | Up to 9 mm | ||

| Maximum forming area | 240 mm x 180 mm | ||

| Forming materials | PVC, PVC/PVdC, Aclar, Triplex (PVC/PE/PVdC), cold-form foil (Alu) | ||

| Lidding materials | Push-through foil, child-resistant foil, peelable (paper) | ||