BLISTER X

About the BLISTER X

A next-generation flat-forming, rotary-sealing, continuous-motion high-output blister packaging machine, BLISTER X, is powerhouse for both large manufacturing and campaign batches. It’s designed with large forming areas for faster forming cycles and is completely servo-controlled, ensuring reliability, flexibility, and productivity of high-quality blister packs consistently.

BLISTER X’s streamlined design exudes sophistication and advanced technology, making it functionally superior and visually striking for any manufacturing environment.

Features |

Benefits |

|

|---|---|---|

| Three-stage heating for film forming |  |

Strict control of ±2.5°C of specified temperature reduces film shrinkage

Ensures the formation of well-defined blister cavities with uniform thickness

Avoids abrupt temperature fluctuations |

| Completely servo-controlled forming, even for cold-form blisters |  |

Enhanced accuracy improving quality, productivity, and life of the machine |

| Servo-controlled rotary vibrator feeding mechanism with high angular velocity |  |

Enhanced feeding efficiency for higher output even at rated cycles |

| Independently servo controlled sealing and counter sealing roller |  |

Superior sealing quality with diamond-type sealing of cold-form and thermoform blisters

Accuracy in both sealing and PRC (print registration control) applications |

| High-speed punching |  |

Significantly higher output, with up to three tracks of blister and combi-packs

Eliminates the limitations of punching in high-speed blister applications |

| High-speed servo-controlled blister dropping |  |

Seamless line integration ensures blister packs land accurately on the conveyor belt and facilitate full integration with cartoning machinery |

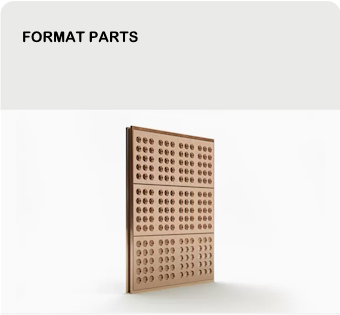

| Large format area (276 mm x 220 mm) |  |

Offers flexibility to produce high output in various combinations – single/twin/three track and combi packs |

Technical specification |

|||

| Forming cycle | Thermoforming | 55 cycles/min | |

| Cold-forming | 45 cycles/min | ||

| Maximum blister size (mm) | 276 mm x 220 mm | ||

| Forming depth | <12 mm | ||

| Forming materials | PVC, PVC/PVdC, Aclar, Triplex (PVC/PE/PVdC), cold-form foil (Alu) | ||

| Lidding materials | Push-through and child-resistant foil/peelable paper | ||