AF Series

ACG’s AF series is a versatile high-speed option with a reputation for robustness over longer production runs.

Models

About the AFT LAB

Creating capsule formulations with different capsule sizes and fill combinations with AFT LAB affords greater flexibility, and ensures pharmaceutical products are ready for technology transfer. A fully automatic R&D-scale capsule filling machine with a small footprint, AFT LAB is the preferred option for laboratories, while its versatile tamping mechanism for powder filling – and its intuitive interface – ensure a smooth scale-up.

Applications

Fills pellets, tablets, micro-tablets, capsules, soft gels, and their combinations in capsules

Features |

Benefits |

|

|---|---|---|

| Allows filling up to four sizes of capsule with a single format part |  |

Saves time and effort while allowing simple scale-up of the development process, without any modification in formulations |

| Can be upgraded to produce up to 25,000 capsules per hour with an easy kit replacement |  |

Scale from R&D to pilot batches on the same machine |

| Capable of filling powders, pellets, tablets, micro-tablets, capsules, soft gels, and their combinations |  |

Diverse filling options widen the scope for experimentation |

| Equipped with caster wheels |  |

Quick and easy to install and use anywhere in your lab

A single system for diverse applications |

Technical specification |

|||

| Stations | 8 | ||

| Capsule sizes | 000 – 5 | ||

|

Maximum speed |

Capsule size 4 |

Capsule size 2 |

Capsule size 1 |

|

6,000 capsules/hr |

12,000 capsules/hr |

25,000 capsules/hr |

|

About the AF 25T

For pilot-scale batches, you want a machine that’s not only small and versatile, but also gives you capsules of dependably accurate fill weight. ACG’s AF 25T is that very machine. Compact and fully automatic, it’s perfect for small batches, and offers multiple capsule filling options for excellent quality output.

Applications

Fills pellets, tablets, micro-tablets, capsules, soft gels, and their combinations in capsules

Features |

Benefits |

|

|---|---|---|

| Precise slug-dosing principle |  |

Provides a better yield of high-quality capsules within optimal weight variation limits, while reducing powder wastage |

| Partial filling capability (up to 25 mg) for capsule sizes 000 to 5 |  |

Allows filling of capsule-based dry powder inhalation (cDPI) formulations with minimum excipients, as well as filling of low-dose API with or without excipients |

| Swift and simple capsule size and product changeover |  |

Minimal downtime means enhanced productivity |

| Capable of filling powders, pellets, tablets, micro-tablets, capsules, soft gels, and their combinations |  |

Diverse filling options allow you to work on a wide range of capsule products |

Technical specification |

|||

| Stations | 8 | ||

| Capsule sizes | 000 – 5 | ||

| Maximum speed | 25,000 capsules/hr | ||

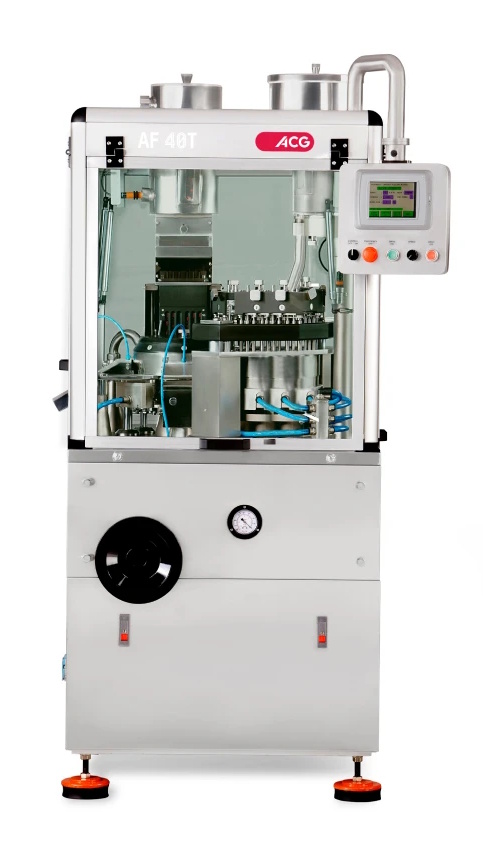

About the AF 40T

With 2,227 successful installations (and counting) across the world, ACG’s AF (automatic filling) series is a versatile high-speed option with a reputation for robustness over longer production runs. Fulfilling all GMP requirements, our AF machines support operations at hundreds of US FDA, EMA, MHRA, WHO and TGA-approved factories and have handled over 3,000 different formulations.

AF 40T is a sturdy production-scale machine for excellent performance with medium-sized batches.

Applications

Fills pellets, tablets, micro-tablets, capsules, soft gels, and their combinations in capsules

Features |

Benefits |

|

|---|---|---|

| High capsule-filling accuracy thanks to a precise slug-dosing principle |  |

Provides a better yield of high-quality capsules within optimal weight variation limits, and reduces powder wastage |

| Partial-filling capability (up to 25 mg) for capsule sizes 000 to 5 |  |

Allows filling of capsule-based dry powder inhalation (cDPI) formulations with minimum excipients, as well as low-dose APIs with or without excipients |

| Quick and easy mechanical changeover |  |

Increases productivity with minimum downtime |

| Capable of filling powders, pellets, tablets, micro-tablets, capsules, soft gels, and combinations thereof |  |

Diverse filling options expand opportunities to a wider range of capsule products |

| Can be integrated with ACCURA – ACG‘s 100% capsule check-weigher |  |

Allows capsule filling and weight-checking in one pass |

Technical specification |

|||

| Capsule sizes | 000 – 5 | ||

| Maximum speed | 40,000 capsules/hr | ||

About the AF 90T

With 2,227 successful installations (and counting) across the world, ACG’s AF (automatic filling) series is a versatile high-speed option with a reputation for robustness over longer production runs. Fulfilling all GMP requirements, our AF machines support operations at hundreds of US FDA, EMA, MHRA, WHO and TGA-approved factories and have handled over 3,000 different formulations.

AF 90T is a sturdy production-scale machine for excellent performance with medium-sized batches

Applications

Fills pellets, tablets, micro-tablets, capsules, soft gels, and their combinations in capsules

Features |

Benefits |

|

|---|---|---|

| High capsule-filling accuracy thanks to a precise slug-dosing principle |  |

Provides a better yield of high-quality capsules within optimal weight variation limits, and reduces powder wastage |

| Partial-filling capability (up to 25 mg) for capsule sizes 000 to 5 |  |

Allows filling of capsule-based dry powder inhalation (cDPI) formulations with minimum excipients, as well as low-dose APIs with or without excipients |

| Quick and easy mechanical changeover |  |

Increases productivity with minimum downtime |

| Capable of filling powders, pellets, tablets, micro-tablets, capsules, soft gels, and combinations thereof |  |

Diverse filling options expand opportunities to a wider range of capsule products |

| Can be integrated with ACCURA – ACG‘s 100% capsule check-weigher |  |

Allows capsule filling and weight-checking in one pass |

Technical specification |

|||

| Capsule sizes | 000 – 5 | ||

| Maximum speed | 90,000 capsules/hr | ||

About the AF 150T

With 2,227 successful installations (and counting) across the world, ACG’s AF (automatic filling) series is a versatile high-speed option with a reputation for robustness over longer production runs. Fulfilling all GMP requirements, our AF machines support operations at hundreds of US FDA, EMA, MHRA, WHO and TGA-approved factories and have handled over 3,000 different formulations.

AF 150T is a sturdy production-scale machine for excellent performance with large batches.

Applications

Fills pellets, tablets, micro-tablets, capsules, soft gels, and their combinations in capsules

Features |

Benefits |

|

|---|---|---|

| High capsule-filling accuracy thanks to a precise slug-dosing principle |  |

Provides a better yield of high-quality capsules within optimal weight variation limits, and reduces powder wastage |

| Partial-filling capability (up to 25mg) for capsule sizes 000 to 5 |  |

Allows filling of capsule-based dry powder inhalation (cDPI) formulations with minimum excipients, as well as low-dose APIs with or without excipients |

| Quick and easy mechanical changeover |  |

Increases productivity with minimum downtime |

| Capable of filling powders, pellets, tablets, micro-tablets, capsules, soft gels, and combinations thereof |  |

Diverse filling options expand opportunities to a wider range of capsule products |

| Can be integrated with ACCURA – ACG‘s 100% capsule check-weigher |  |

Allows capsule filling and weight-checking in one pass |

Technical specification |

|||

| Capsule sizes | 000 – 5 | ||

| Maximum speed | 150,000 capsules/hr | ||

About the AF 200T

With 2,227 successful installations (and counting) across the world, ACG’s AF (automatic filling) series is a versatile high-speed option with a reputation for robustness over longer production runs. Fulfilling all GMP requirements, our AF machines support operations at hundreds of US FDA, EMA, MHRA, WHO and TGA-approved factories and have handled over 3,000 different formulations.

AF 200T is a sturdy production-scale machine for excellent performance with large batches.

Applications

Fills pellets, tablets, micro-tablets, capsules, soft gels, and their combinations in capsules

Features |

Benefits |

|

|---|---|---|

| High capsule-filling accuracy thanks to a precise slug-dosing principle |  |

Provides a better yield of high-quality capsules within optimal weight variation limits, and reduces powder wastage |

| Partial-filling capability (up to 25mg) for capsule sizes 000 to 5 |  |

Allows filling of capsule-based dry powder inhalation (cDPI) formulations with minimum excipients, as well as low-dose APIs with or without excipients |

| Quick and easy mechanical changeover |  |

Increases productivity with minimum downtime |

| Capable of filling powders, pellets, tablets, micro-tablets, capsules, soft gels, and combinations thereof |  |

Diverse filling options expand opportunities to a wider range of capsule products |

| Can be integrated with ACCURA – ACG‘s 100% capsule check-weigher |  |

Allows capsule filling and weight-checking in one pass |

Technical specification |

|||

| Capsule sizes | 000 – 5 | ||

| Maximum speed | 200,000 capsules/hr | ||