Cartoning Machines

Packaging is an important component of any business that manufactures products for the market. It is the packaging that reflects the brand values and influences the consumer’s purchasing decision. And to ensure efficient and cost-effective packaging, having the right cartoning equipment is critical. Cartoning equipment is one such machinery that helps simplify and streamline the packaging process.

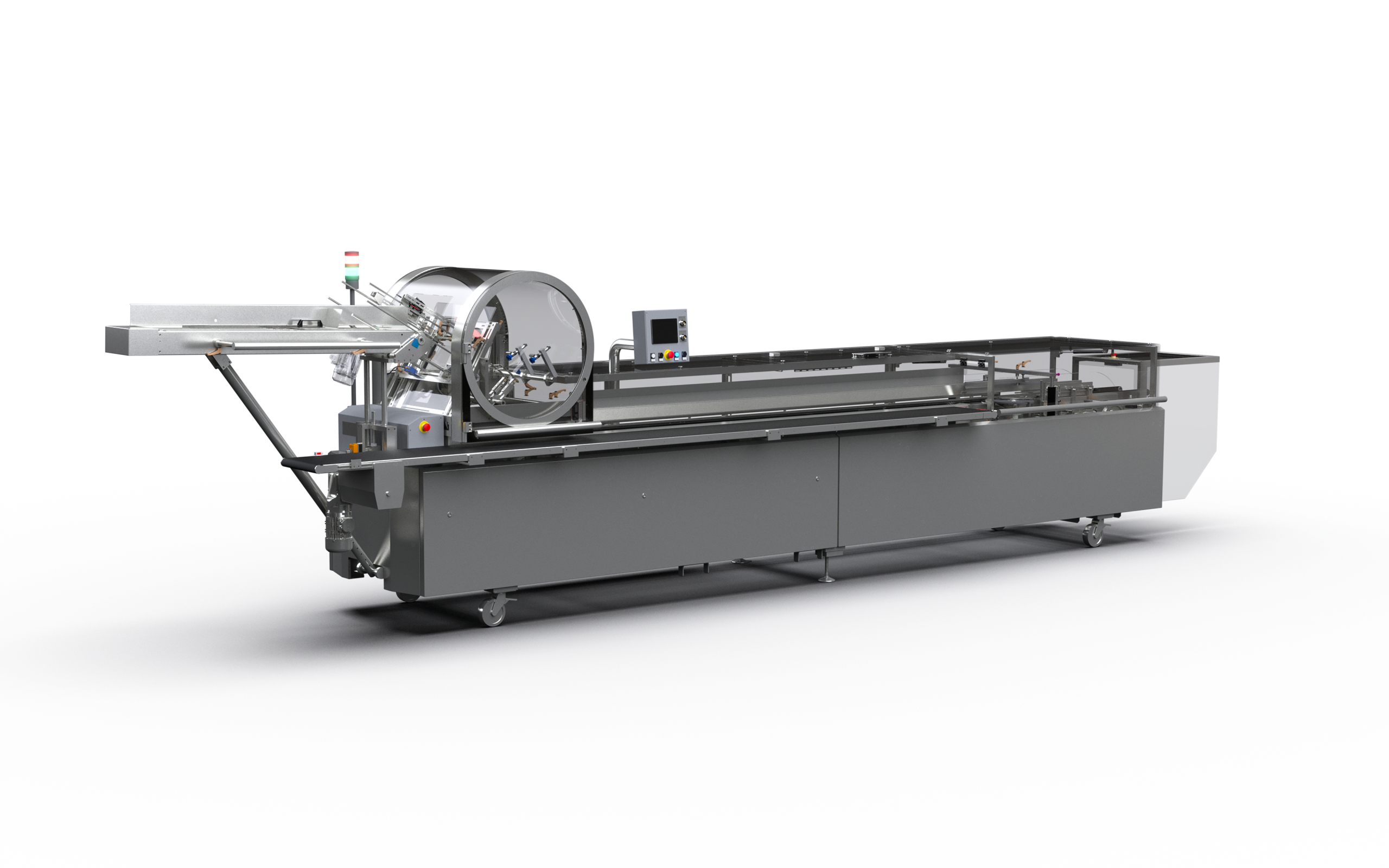

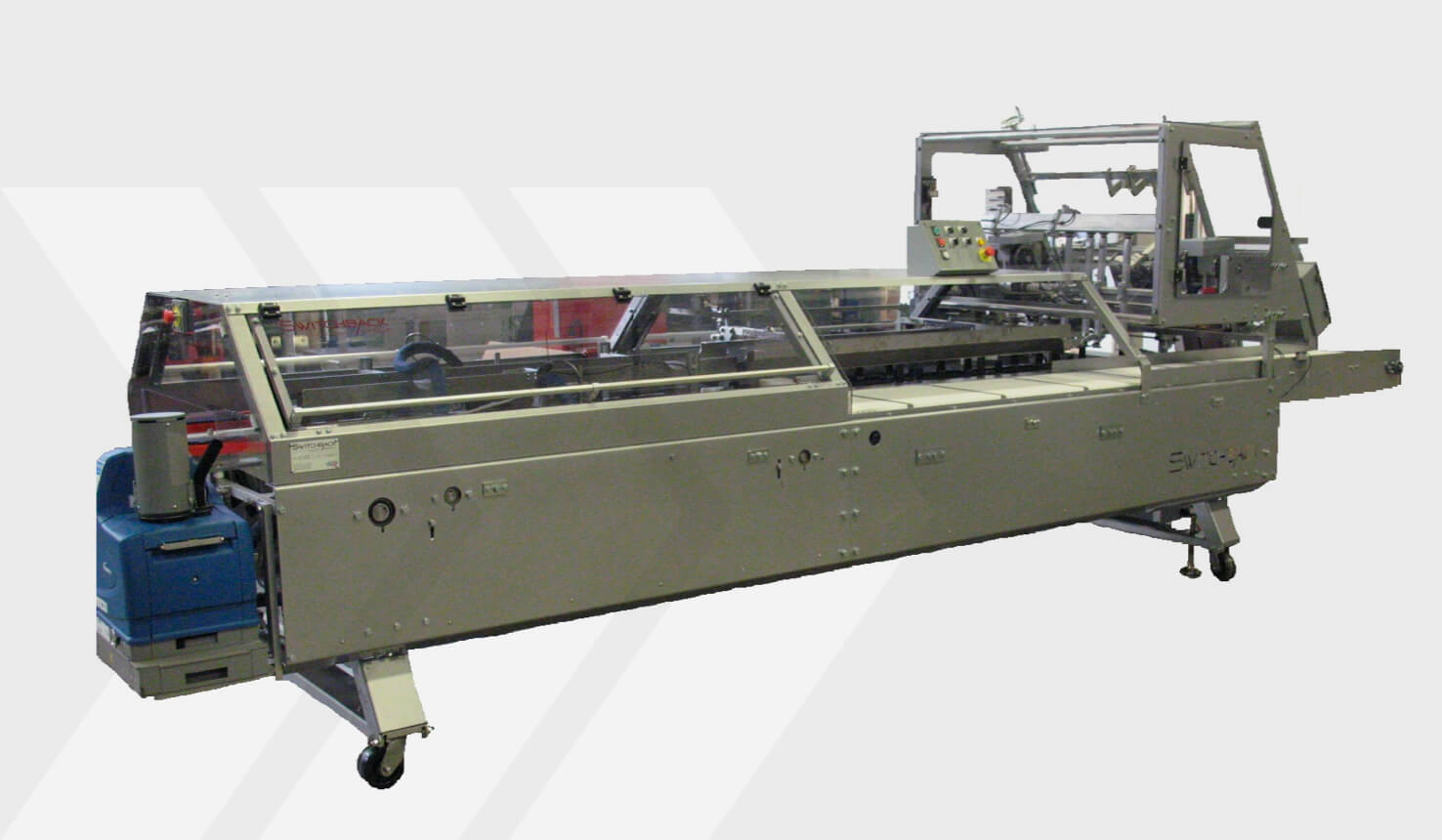

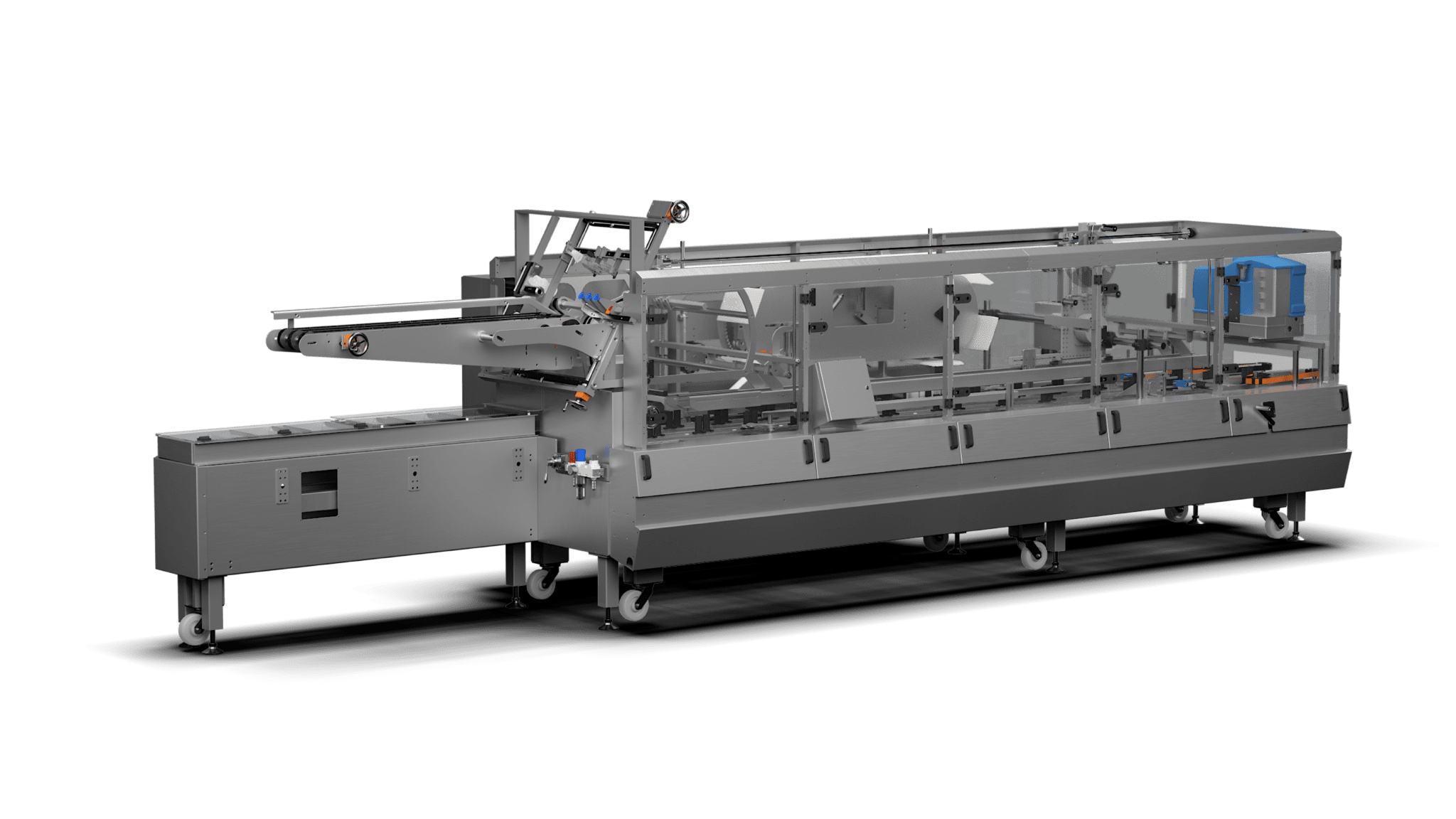

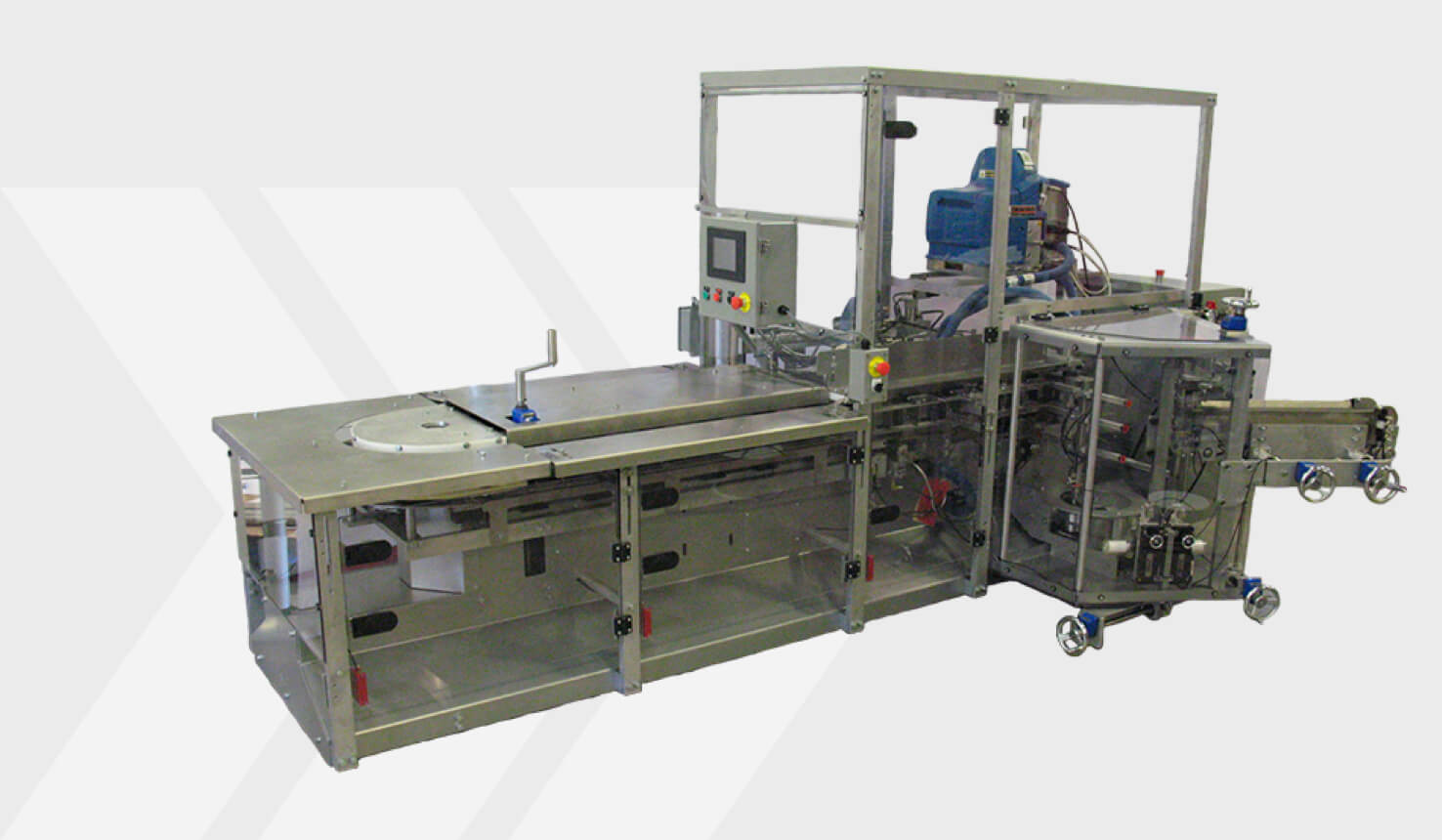

Side Load Cartoners

- Max Speed (cpm): 500

- Hygienic, continuous motion side load cartoner

- Handles a large range of carton sizes

- Intelligent Machine Interface (iMi) for optimised productivity

- Open design for optimal access

- Quick and simple change overs for flexible and high efficiency production

- Modular design for future modifications or redeployment

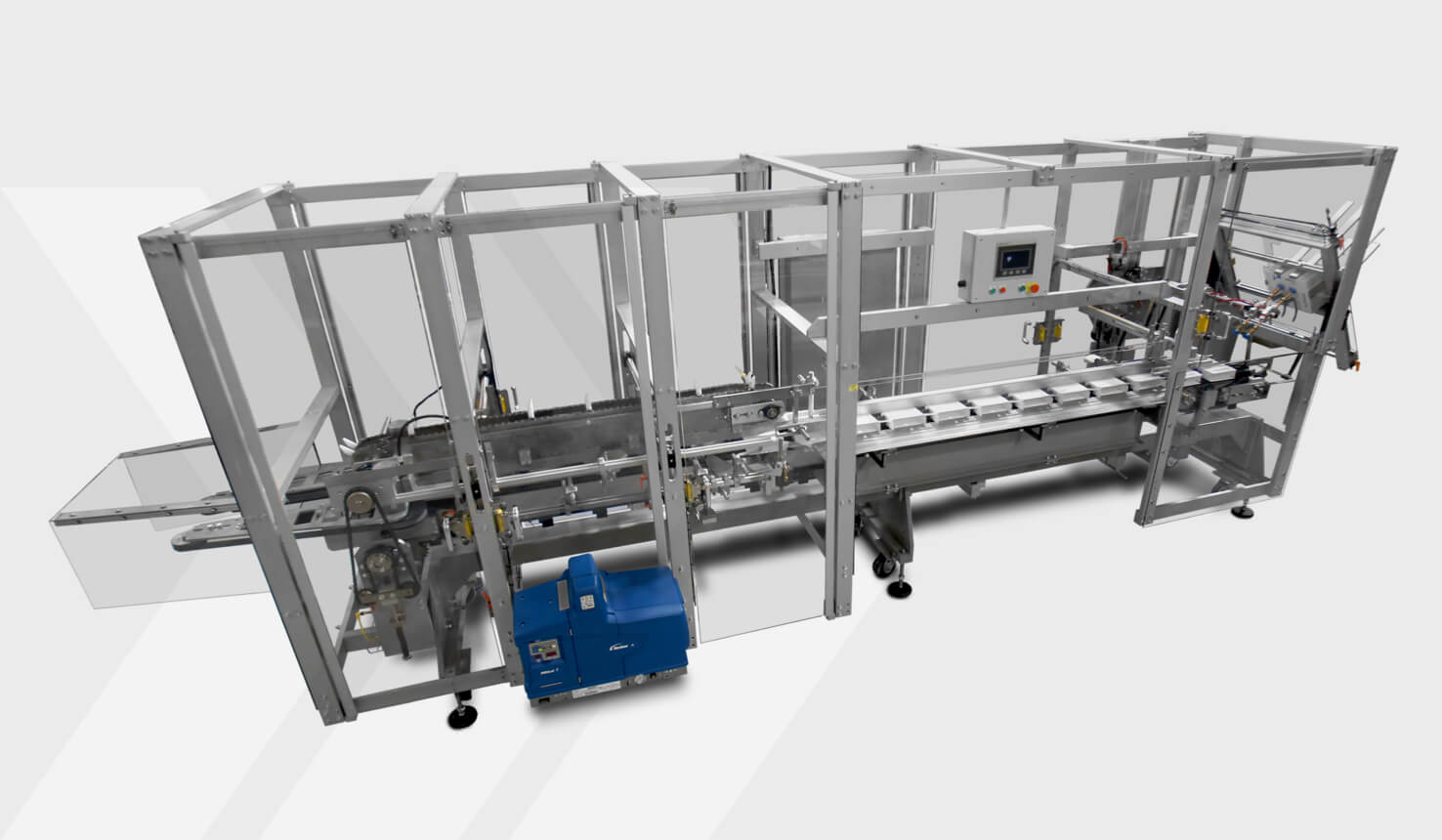

- Max Speed (cpm): 50-90

- Heavy-duty construction

- Compact footprint

- Runs 4,5 & 12 pack patterns

- Elevated frame for sanitation

- Full product control thought the machine cycle

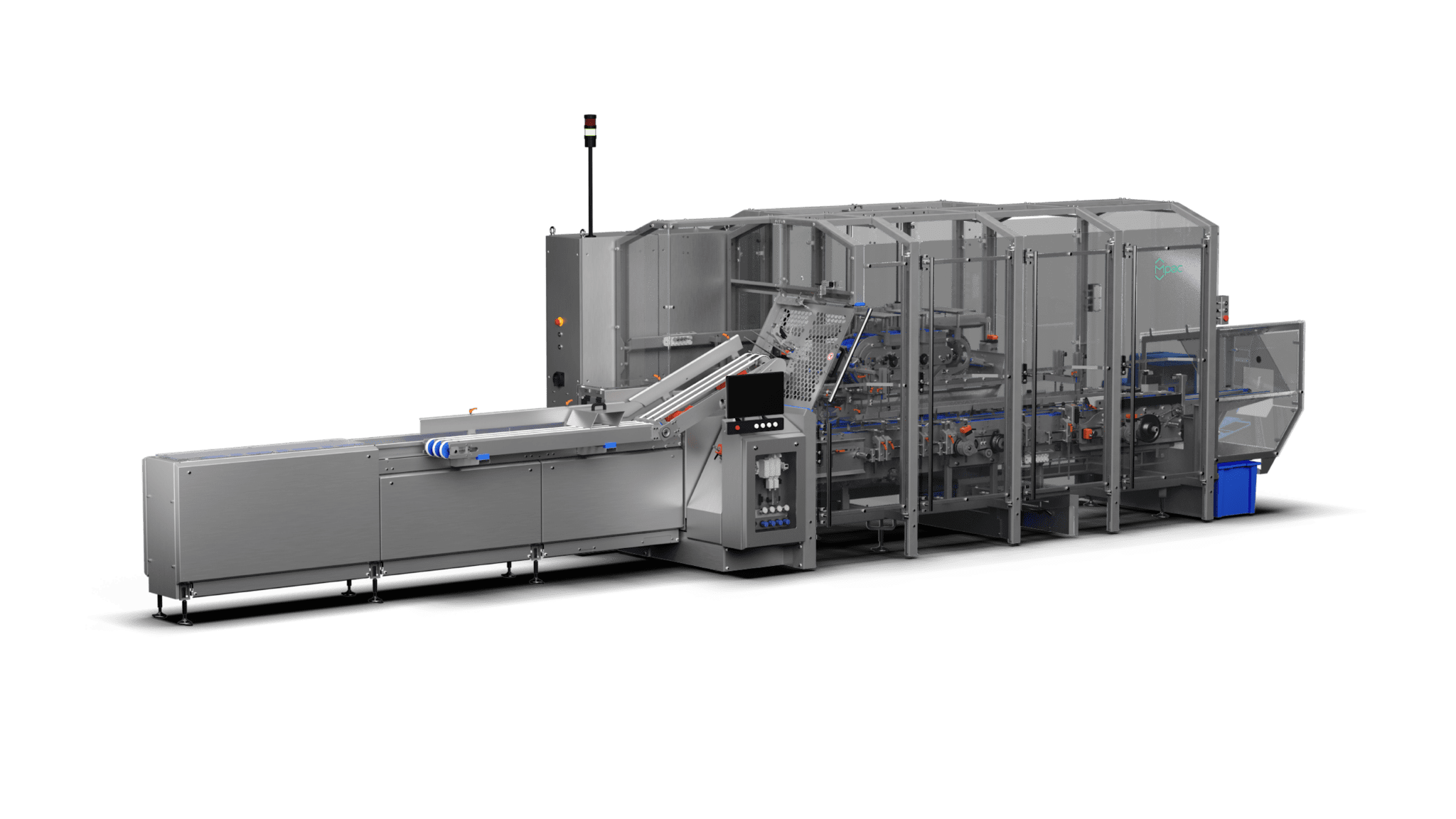

- Max Speed (cpm): 250

- Robust design

- High performance and longevity

- Ability to customise your solution

- High-speed for small product applications

- Wide variety of in-feed and carton sizes available

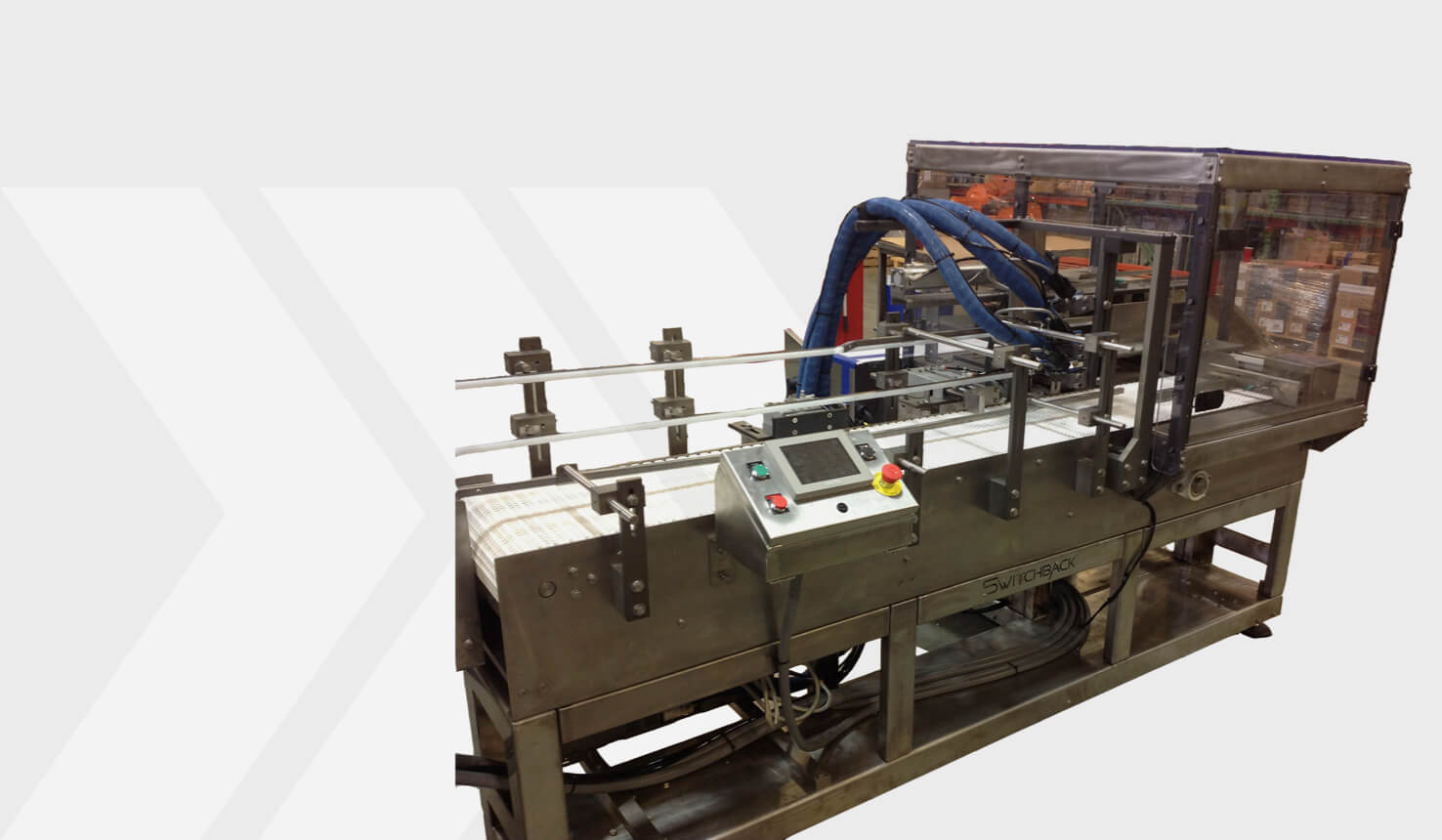

- Max Speed (cpm): 70

- Heavy-duty construction

- High-speed cartoning

- Compact footprint

- Runs 4, 6, 7, 9, 12 & 15 pack patterns.

- Runs 18 and 24 pack cartons when utilising traypacker

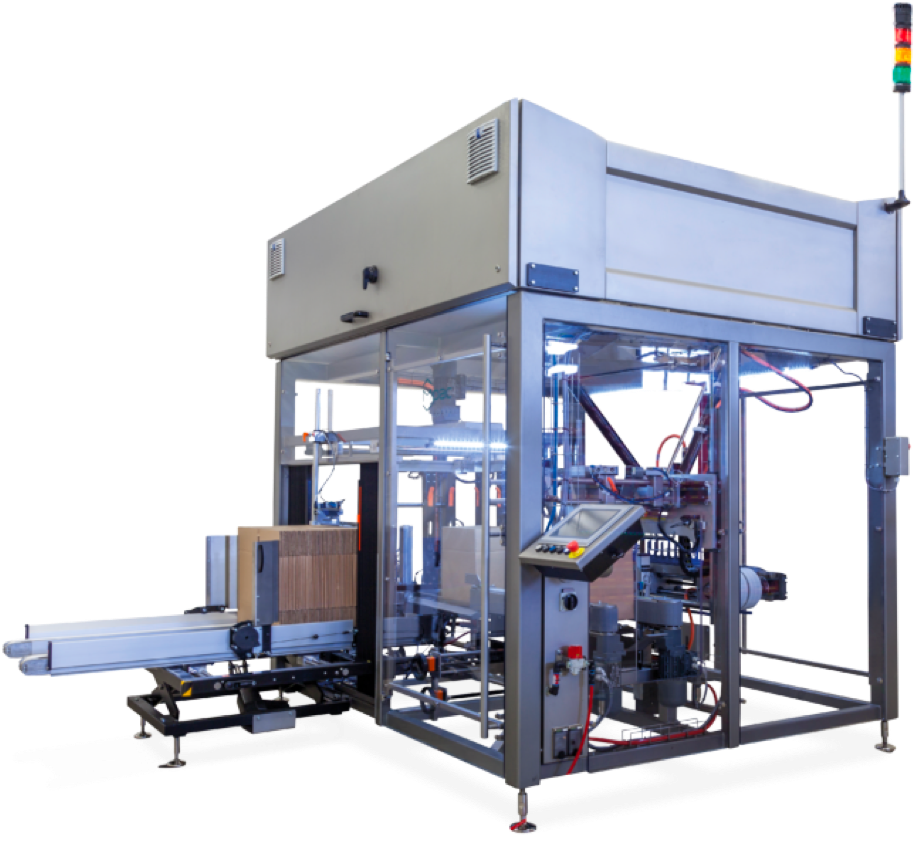

Top Load Cartoners

Vertical Load Cartoners

- Max Speed (cpm): 150

- Highly flexible

- Handles a wide variety of carton sizes and styles

- Large operator loading area

- Touch screen control

- Quick change, 3-sided carton buckets

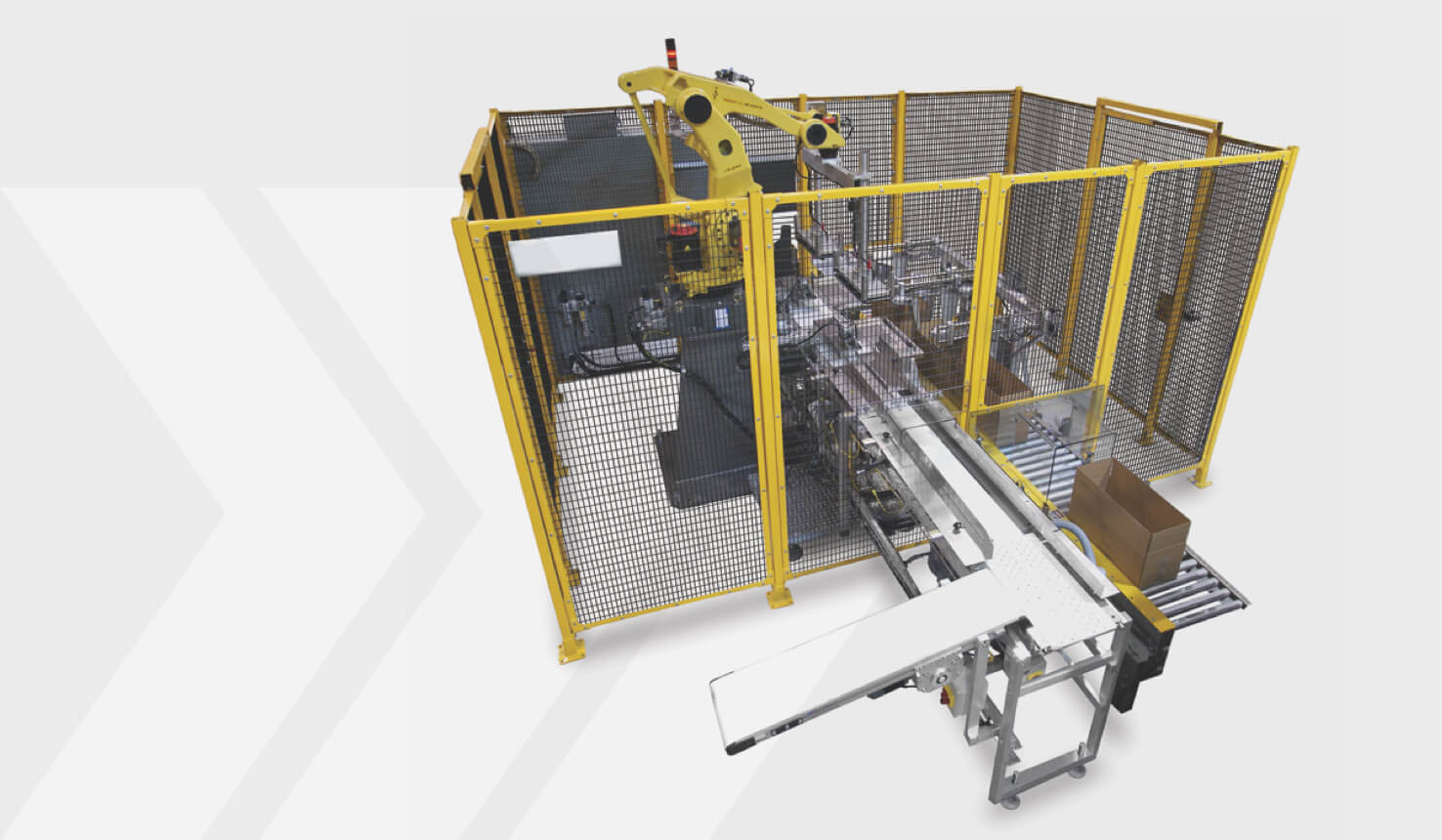

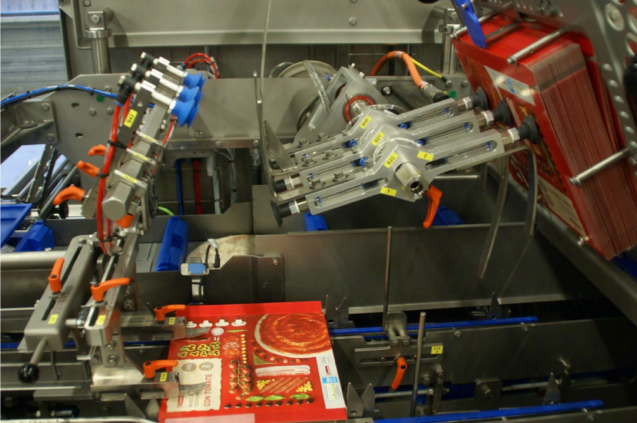

Product Handling and Infeed

Well-designed infeed systems carefully handle products though the collation process, adjusted to your unique packaging requirements. The extensive experience and world-beating infeed machine technology means it can deliver a successful solution, whatever your application.

Applications:

The advanced product handling and infeed automation systems can handle a variety of applications, including:

- Sticks sachets and pouches

- Bottles and jars

- Facial tissues

- Blister strips

- Bags

- Frozen food

- Flow wrap

- Trays

- Consumer goods