Flow Wrapper – Top Center Sealing

Horizontal Form Fill and Seal Flow Wrapper

The Top Sealing Flow Wrapper is an ideal packaging machine for soft, irregular or difficult-to-handle product packaging and for multi packs as well, with the products transported on the top of the film from bag former to cutting section, minimizing jams and ensuring superior package appearance.

Flow pack machine for ice pops, multiple products, etc.

The flow wrapper is ideal for soft, irregular or difficult-to-handle products packaging, and the machine with 2nd axis servo driven for film tension control is available as an option.

With quality construction and Siemens PLC control, the flow wrapper can pack a variety of industrial products, reaching productivity goals and satisfying budget requirements.

Features:

- Powder coating machine frame construction.

- 1 axis servo motor drive.

- One set of rotary end sealing jaw.

- One set of auto centering reel holder.

- Two sets of inverted center sealing wheel, one cold & one heated.

- Siemens PLC program control.

- Shinko P.I.D. temperature control modular.

- Japanese Yaskawa inverter speed variation.

- Japanese Panasonic photocell for film registration.

- 7″ touch panel with 50 sets of products data memories.

- Adjustable bag former or modular bag forming box.

- Transfer belt under center sealing station.

- 2 M long in-feed conveyor with wider pusher.

- Safety protection guards for end sealing station.

- End sealer over-load protection device.

- European CE safety standard.

Specifications:

| Model No. | S-5535-IV | S-5547-IV | S-5561-IV |

| Capacity (PPM) | 30 ~ 200 | 30 ~ 160 | 20 ~ 140 |

| Bag Length (mm) | 70 ~ 350 | 70 ~ 350 | 130 ~ 500 |

| Max. Film Width (mm) | 350 | 470 | 610 |

| Max. Product Width (mm) | 145 | 190 | 265 |

| Max. Product Height (mm) | 30 / 60 / 90 mm with jaws Dia. in 88 / 120 / 160 mm | ||

| Electricity | 4.1 KW – AC 220 Volt – 3 phase + Ground | ||

The Max. product height is according to the applications & products range.

Higher product is available as requested.

Packaging Applications:

- Bakery

- Biscuits & Snacks

- Candy & Confectionery

- Refrigerated & Frozen Food

- Fresh

- Shrink Packaging

- Wet Wipes / Tissue

- Printing Items

- Detergents

- Pharmaceutical & Medical

- Hardware & Tool

- Instant Noodles

- Miscellaneous

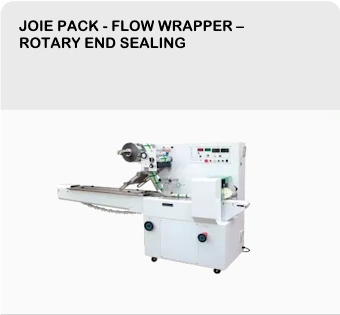

Flow pack machine for ice pops, multiple products, etc.

Flow wrapper with top sealing which can pack a variety of industrial products, reaches productivity goals and satisfies budget requirements.

The machine is an ideal solution for soft items, vegetables and fruits, etc.

Features:

- Powder coating machine frame construction.

- 3 axis servo motor drive for in-feed, fin sealing and end sealing.

- Yaskawa motion controller.

- 10.4″ colorful touch panel (HMI).

- 100 sets of product data memories.

- Shinko P.I.D. temperature control modular.

- One set of rotary end sealing jaw.

- One set of auto centering reel holder.

- Two sets of inverted center sealing wheel, one cold & one heated.

- Japanese Panasonic photocell for film registration.

- Transfer belt under center sealing station.

- 2 M long top chain in-feed conveyor with wider pusher.

- Safety protection guards for sealing station.

- End sealer over-load protection device.

Specifications:

| Model No. | S-5635-IV | S-5647-IV | S-5661-IV |

| Capacity (PPM) | 30 ~ 200 | 30 ~ 160 | 20 ~ 140 |

| Bag Length (mm) | 70 ~ 350 | 70 ~ 350 | 130 ~ 500 |

| Max. Film Width (mm) | 350 | 470 | 610 |

| Max. Product Width (mm) | 145 | 190 | 265 |

| Max. Product Height (mm) | 30 / 60 / 90 mm with jaws Dia. in 88 / 120 / 160 mm | ||

| Electricity | 4.1 KW – AC 220 Volt – 3 phase + Ground | ||

The Max. product height is according to the applications & products range.

Higher product is available as requested.

Packaging Applications:

- Bakery

- Biscuits & Snacks

- Candy & Confectionery

- Refrigerated & Frozen Food

- Fresh

- Shrink Packaging

- Wet Wipes / Tissue

- Printing Items

- Detergents

- Pharmaceutical & Medical

- Hardware & Tool

- Instant Noodles

- Miscellaneous

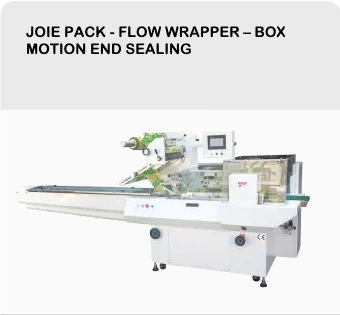

Flow pack machine for frozen cakes, ice pops, cheese, etc.

Great packaging solution for soft items, vegetables, and fruits, etc., the wrapper produces finished packages with less air and achieves optimal hermetic sealing.

Features:

- Powder coating machine frame construction.

- 3 axis servo motor drive for in-feed, fin sealing and end sealing.

- Yaskawa motion controller.

- 10.4″ colorful touch panel (HMI).

- 100 sets of product data memories.

- Shinko P.I.D. temperature control modular.

- One set of box motion end sealing jaw.

- One set of auto centering reel holder.

- Two sets of inverted center sealing wheel, one cold & one heated.

- Japanese Panasonic photocell for film registration.

- Transfer belt under center sealing station.

- 2 M long top chain in-feed conveyor with adjustable guides.

- Safety protection guards for end sealing station.

- End sealer over-load protection device.

- European CE safety standards.

Specifications:

| Model No. | S-5635-IV-BX | S-5647-IV-BX | S-5661-IV-BX |

| Capacity (PPM) | 20 ~ 90 | 20 ~ 90 | 20 ~ 90 |

| Bag Length (mm) | 70 ~ 350 | 70 ~ 350 | 130 ~ 500 |

| Max. Film Width (mm) | 350 | 470 | 610 |

| Max. Product Width (mm) | 145 | 190 | 265 |

| Max. Product Height (mm) | 30 / 60 / 90 mm with jaws Dia. in 88 / 120 / 160 mm | ||

| Electricity | 4.1 KW – AC 220 Volt – 3 phase + Ground | ||

The Max. product height is according to the applications & products range.

Higher product is available as requested.

Packaging Applications:

- Bakery

- Biscuits & Snacks

- Candy & Confectionery

- Refrigerated & Frozen Food

- Fresh

- Shrink Packaging

- Wet Wipes / Tissue

- Printing Items

- Detergents

- Pharmaceutical & Medical

- Hardware & Tool

- Instant Noodles

- Miscellaneous