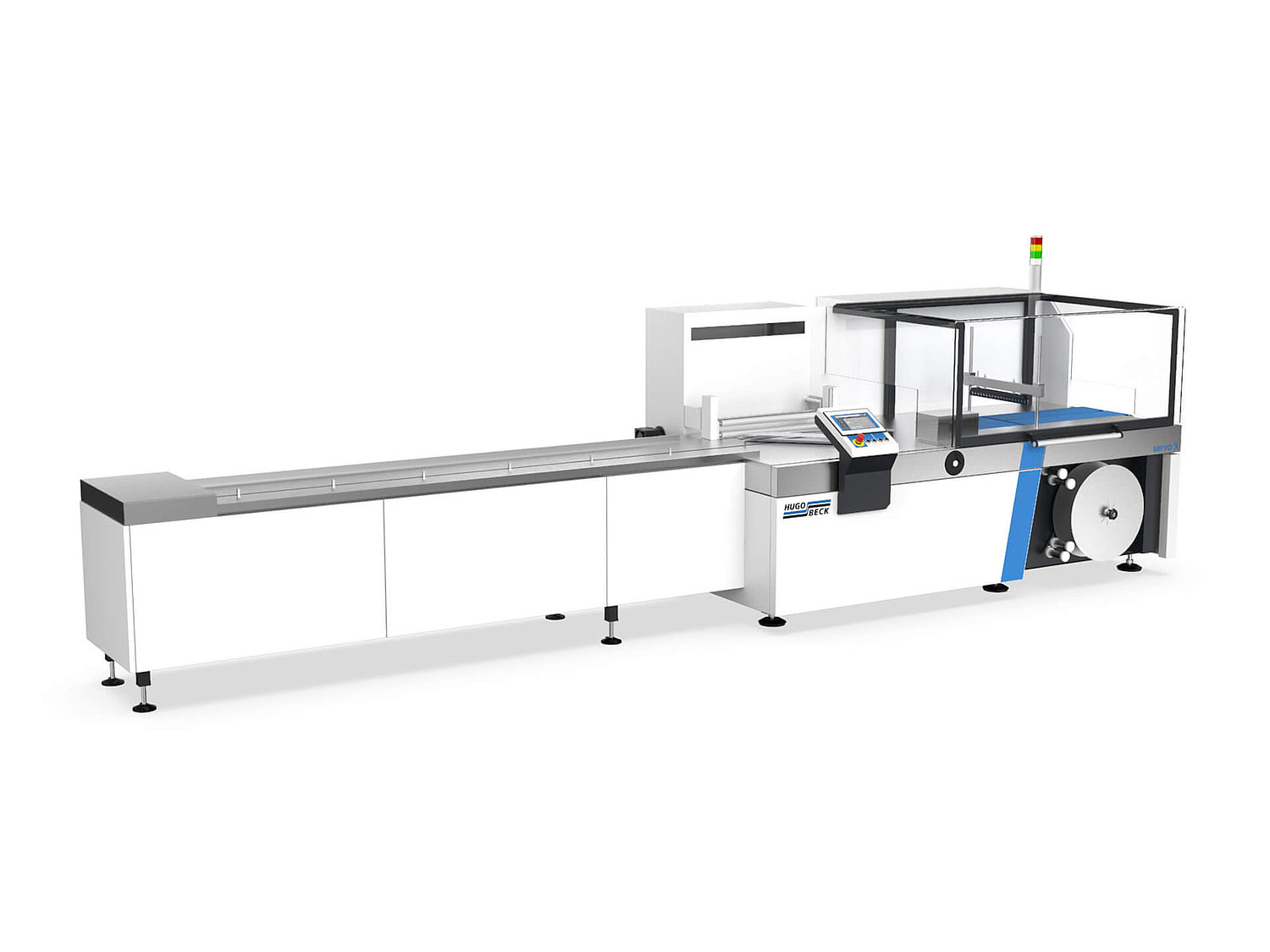

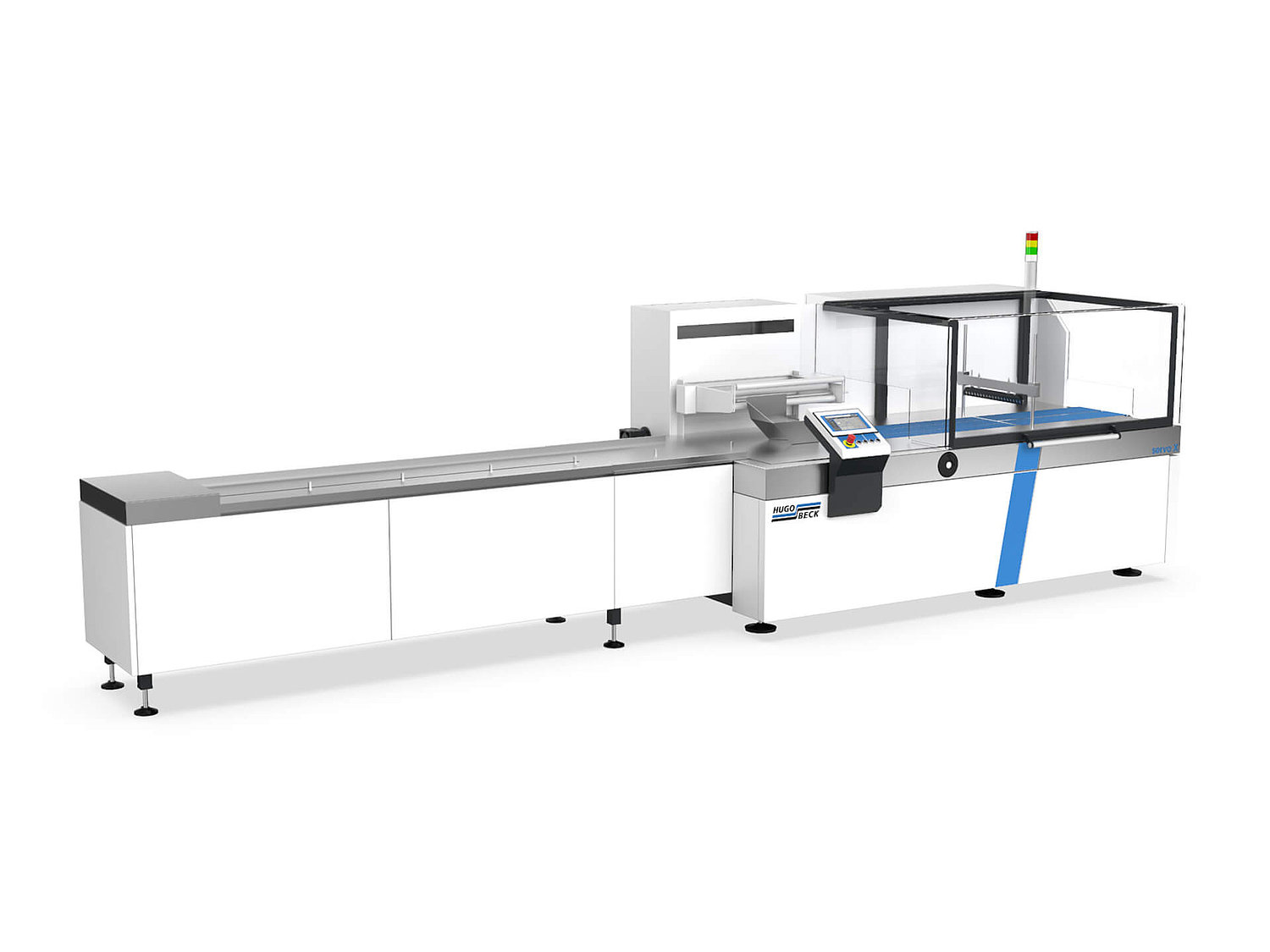

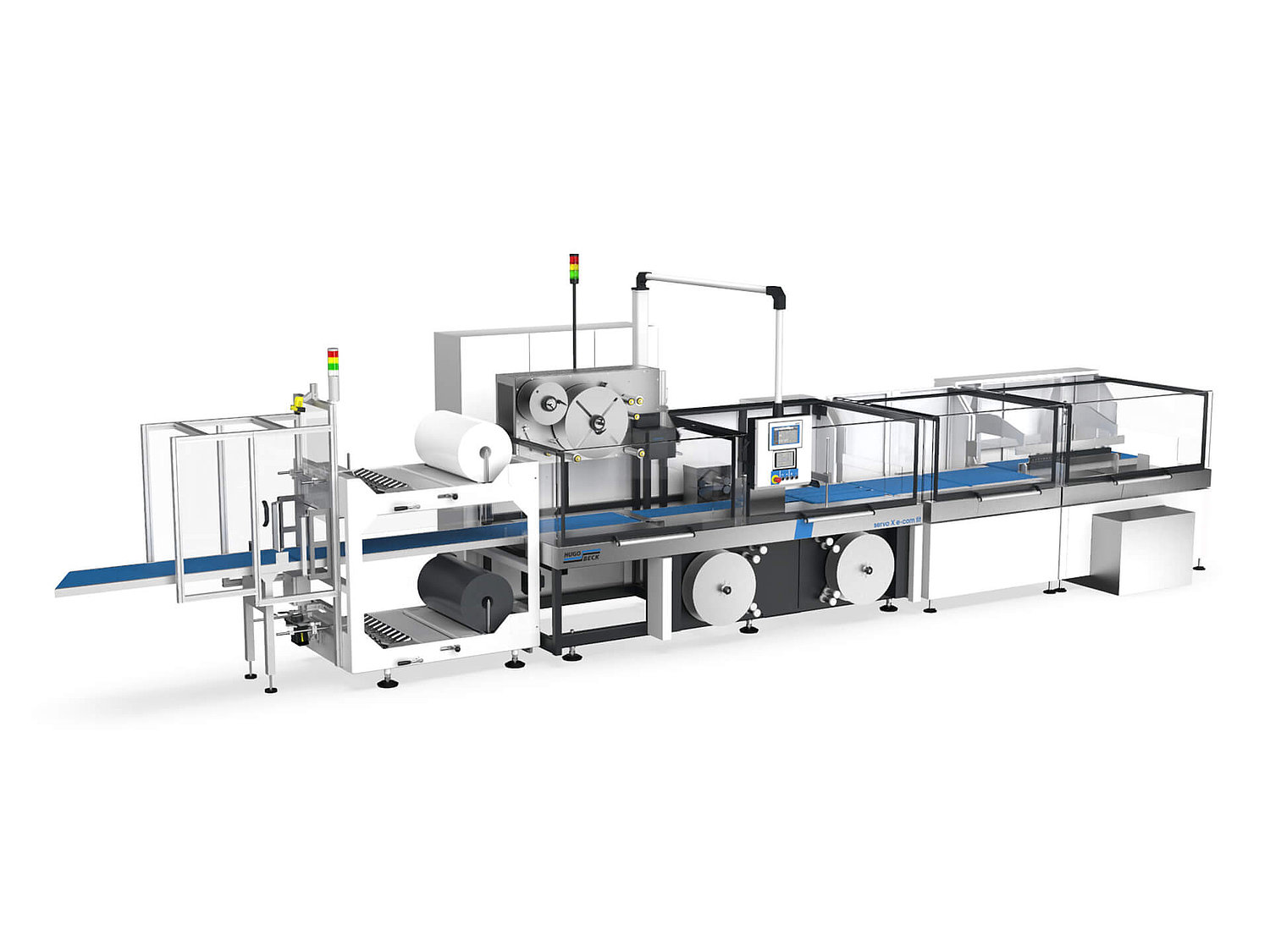

Servo Series – Horizontal Form Fill and Seal Machines

Available in five performance ranges and numerous variants. These machines cover the broadest possible range of horizontal film packaging applications – with maximum modularity.

Highlights

- Extremely tight bag packaging with lowest possible material use and optimum processing of the most diverse of film thickness and film types (e.g. recyclable mono-material films, recycled content films, ultra thin films from approx. 7 µm, etc.)

- Siemens TIA Portal or Rockwell Automation control system; free remote service

- Smart user guidance via CoPilot and touch screen

- Maximum serviceability and maintainability thanks to perfect access and numerous maintenance-free components

- Easy line integration and connectivity with higher-level systems

- Industry 4.0 Ready

- Optional monitoring, analysis and visualisation of machine and operating data via the Hugo Beck Cockpit

Technical Data

| Product infeed | manual as standalone/automatic in line |

| Film | centre-folded and flat film, e.g. PE, PO, PP, bio films, recycled content films |

| Product Size | Length: from 45 mm Width: 10 – 450 mm Height: max. 250 mm |

| Capacity | Five performance classes up to 15.000 cycles/hour up to 250 cycles/minute |

| Versions | Side seal or bottom cut seal, overlap on top, bottom overlap with or without sealing/ionisation |

| Downloads | Data sheet servo X series |

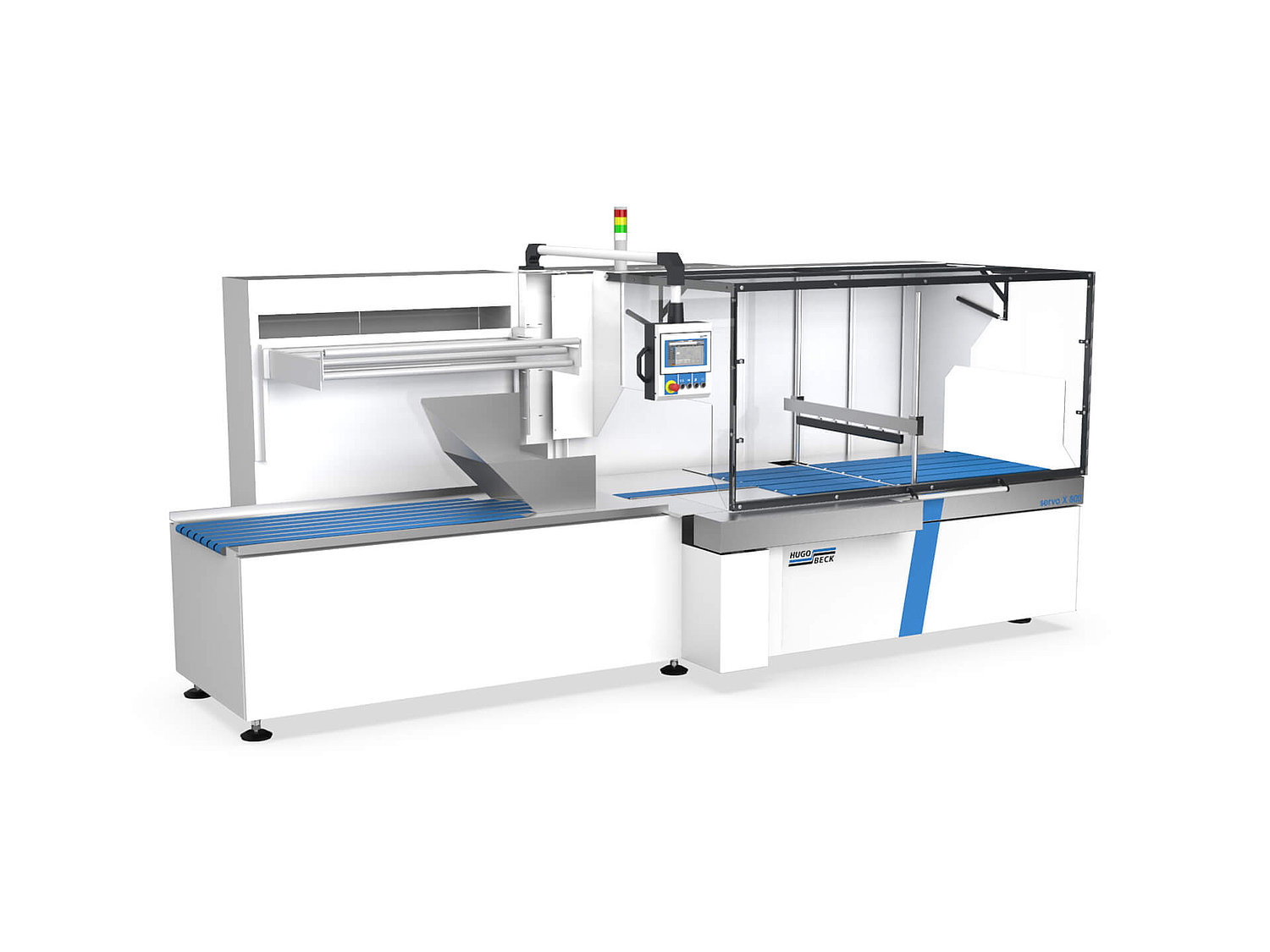

servo X 800 machines are the most powerful of film packaging machines in the large-format segment – with maximum modularity. Suitable for products with a width of up to 800 mm and a length from 150 mm.

Highlights

- Extremely tight bag packaging with lowest possible material use and optimum processing of the most diverse of film thickness and film types (e.g. recyclable mono-material films, recycled content films, ultra thin films from approx. 7 μm, etc.)

- Siemens TIA Portal or Rockwell Automation control system; free remote service

- Smart user guidance via CoPilot and touch screen

- Maximum serviceability and maintainability thanks to perfect access and numerous maintenance-free components

- Easy line integration and connectivity with higher-level systems, Industry 4.0 Ready

- Optional monitoring, analysis and visualisation of machine and operating data via the Hugo Beck Cockpit

Technical Data

| Product infeed | manual as standalone/automatic in line |

| Film | centre-folded and flat film, e.g. PE, PO, PP, bio films, recycled content films |

| Product Size | Length: from 150 mm Width: 150 – 800 mm Height: max. 450 mm |

| Capacity | up to 5000 cycles/hour up to 84 cycles/minute |

| Versions | Side seal, bottom overlap with or without sealing/ionisation |

| Downloads | Data sheet servo X 800 |

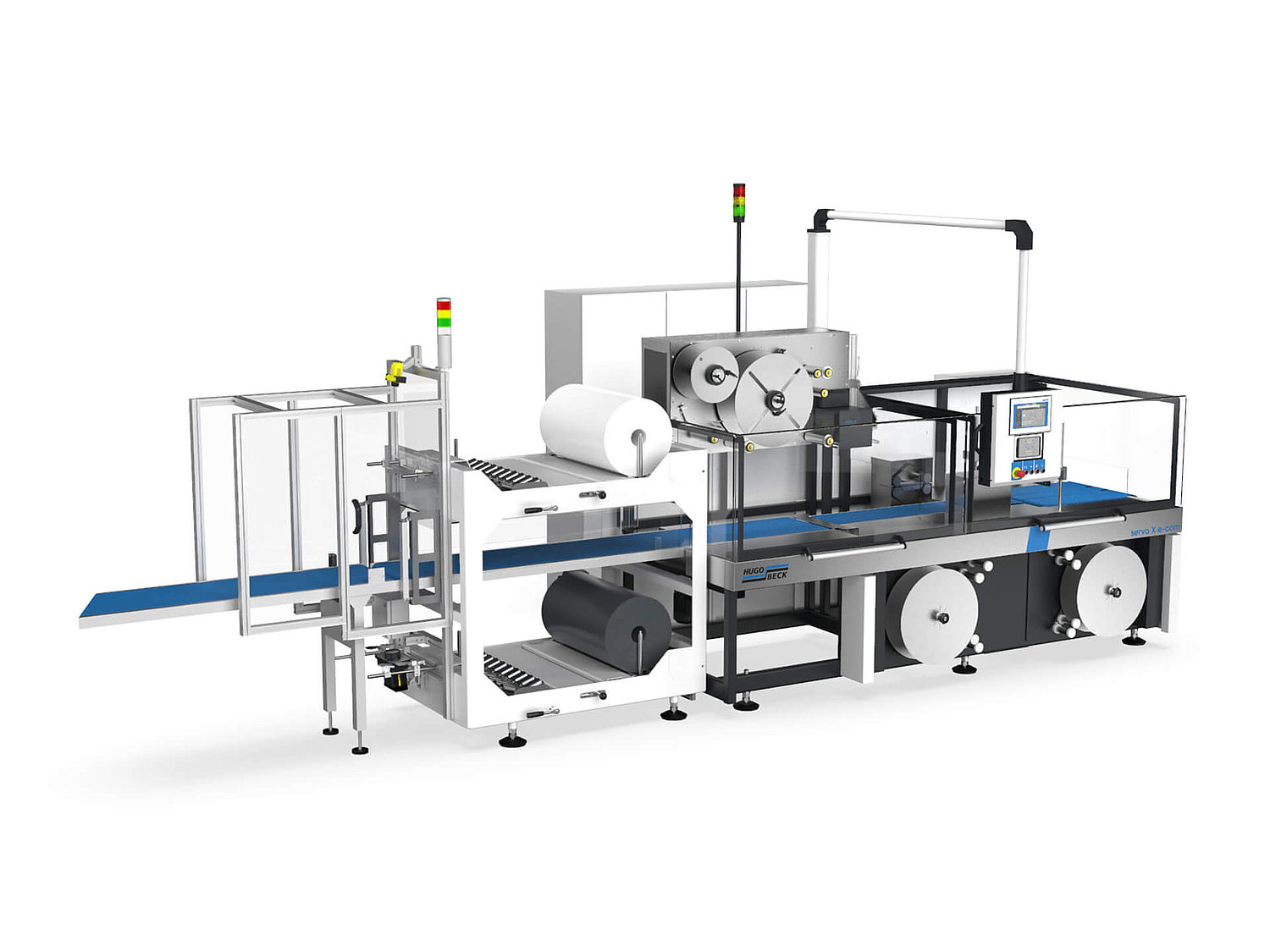

Film packaging for e-commerce, mail order, logistics. Automatic adaptation to the product’s length as standard, to the width as an option. Packs goods with upper and lower film.

Highlights

- Tight bag packaging with lowest possible material use and optimum processing of the most diverse of film thickness and film types (e.g. recyclable mono-material films, recycled content films, etc.)

- Each bag size is automatically adapted to the product’s length as standard, and also to the product’s width as an option

- Siemens TIA Portal or Rockwell Automation control system; free remote service

- Integrated scanner with a controller for product detection and creation of a shipping label, which is continuously dispensed directly onto the film without an applicator

- As an option, easy-opening perforation and inserting of a double-sided adhesive tape for resealing the bag

- As an option, “Easy Splice” – film change by thermal welding

- Optimised user-friendliness and accessibility

- Connection to ERP or control systems

- Industry 4.0 Ready

- Optional monitoring, analysis and visualisation of machine and operating data via the Hugo Beck Cockpit

Technical Data

| Product infeed | manual as standalone/automatic in line |

| Product Size | Length: 100 – 600 mm Width: 150 – 500 mm Height: max. 200 mm |

| Capacity | servo X e-com: approx. 3000 cycles/h servo X e-com fit: approx. 1800 cycles/h |

| Film | Upper/lower film: e.g. PE flat film 30 – 100 μm, recycled content film |

| Downloads | Data sheet servo X e-com (fit) |

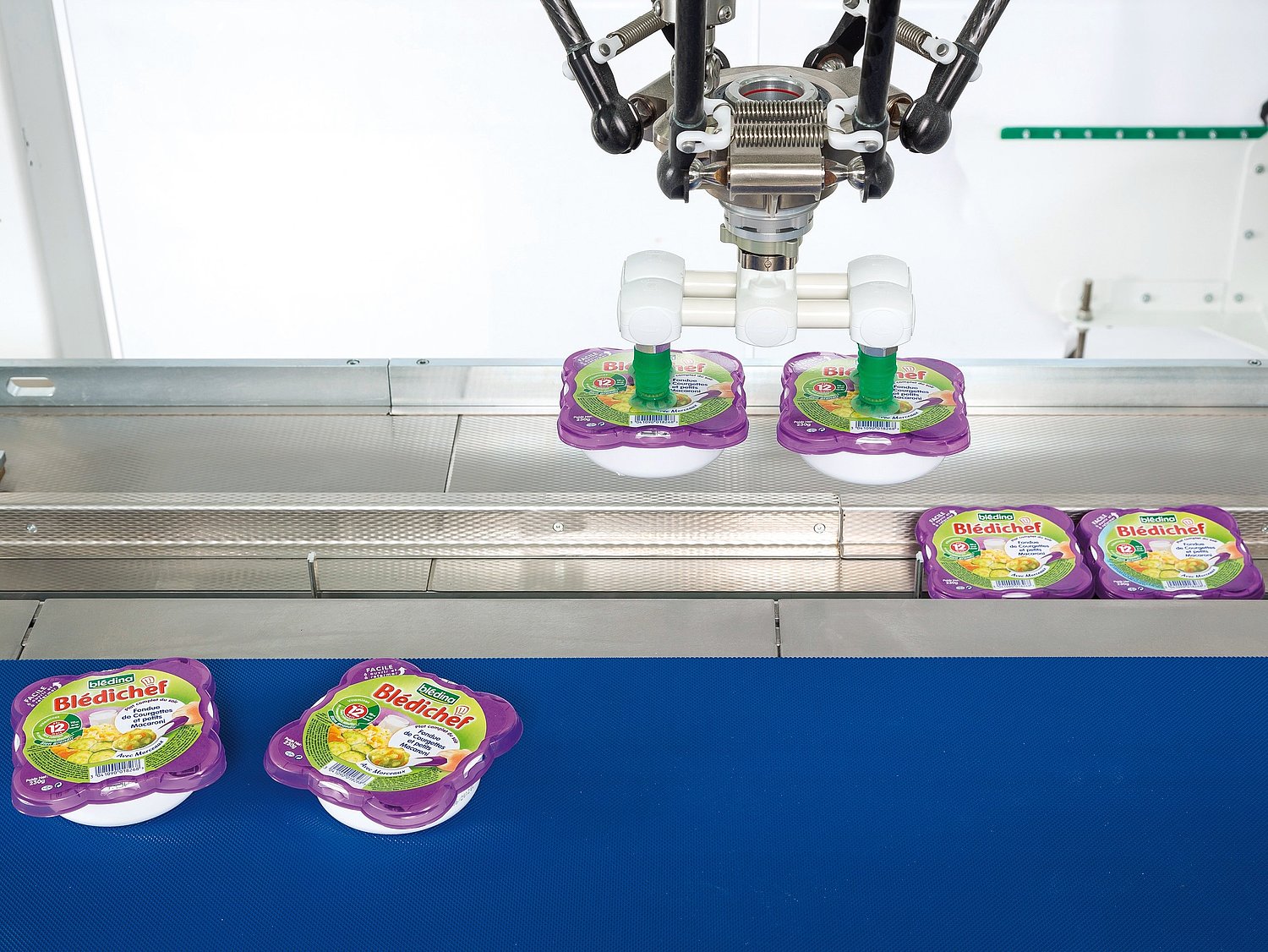

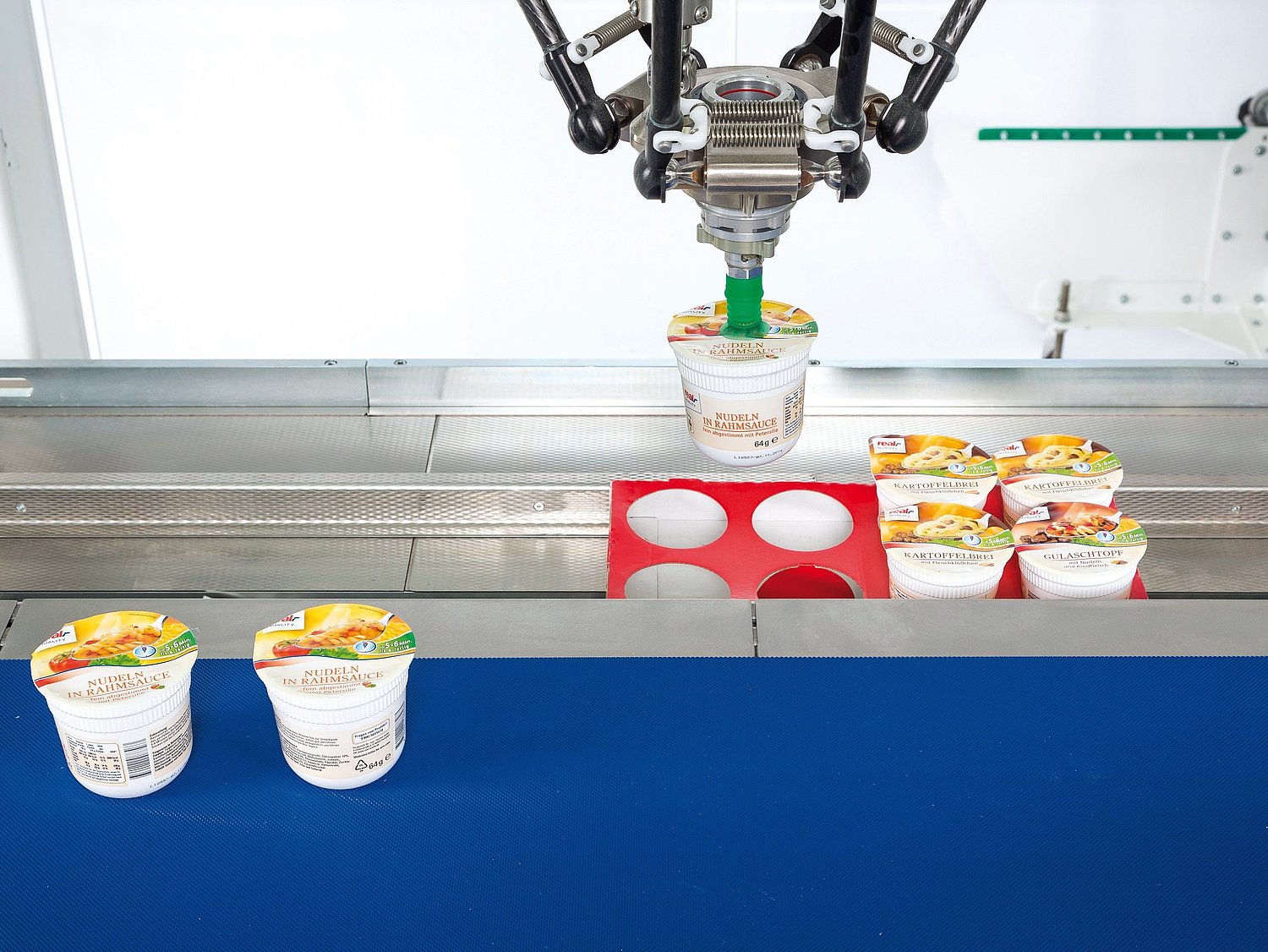

AUTOMATION – Robots and Handling SYSTEMS

Efficient and flexible automation solutions

Hugo Beck can claim a decade-long development tradition when it comes to automation. We offer support with our expertise throughout the entire automation process, from project planning and manufacture right through to integration into complex packaging lines. Handling systems such as portals, grouping solutions, stacking and counting devices, cross pusher to name but a few, are integrated reliably into the packaging solutions by our technicians.

Furthermore, various robots’ systems are used across many industries for the automated feeding of products, helping to for example grip, position, stack, group, stage products. From a parallel robot (also known as a spider robot) all the way through to a SCARA robot – anything is flexibly possible and delivered fully integrated according to each customer ‘s needs.

Both robots and handling systems can all be purchased independently of Hugo Beck packaging machines.

Benefits

- Complete solutions from a single source

- Flexible technology options

- Customised handling systems

- Integration of robot systems from a variety of manufacturers

- Integration into existing and projected packaging lines